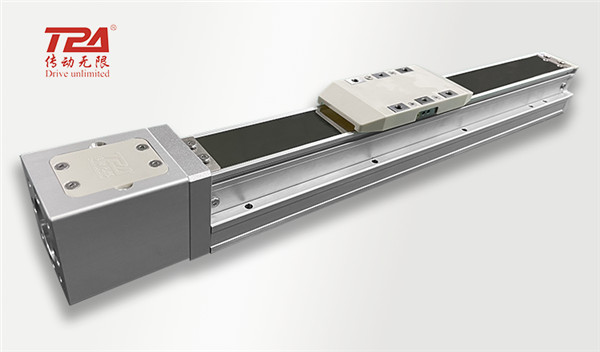

I-actuator yomugqa wohlobo lwesikulufu sebhola ikakhulukazi iqukethe isikulufu sebhola, umhlahlandlela womugqa, iphrofayela ye-aluminium alloy, isisekelo sokusekela isikulufu sebhola, ukuhlanganisa, injini, inzwa yomkhawulo, njll.

Isikulufu sebhola: Isikulufu sebhola silungele ukuguqula ukunyakaza okujikelezayo kube ukunyakaza okuqondile, noma ukunyakaza okuqondile kube ukunyakaza okujikelezayo. Isikulufu sebhola siqukethe isikulufu, inati nebhola. Umsebenzi wayo ukuguqula ukunyakaza kwe-rotary kube ukunyakaza okuqondile, okuyisandiso esengeziwe nokuthuthukiswa kwesikulufu sebhola. Ngenxa yokumelana kwayo okuncane nokungqubuzana, isikulufu sebhola sisetshenziswa kakhulu kumishini ehlukahlukene yezimboni namathuluzi anembayo. Ukunyakaza komugqa okunembayo okuphezulu kungafinyelelwa ngaphansi komthwalo omkhulu. Kodwa-ke, isikulufu sebhola asinalo ikhono lokuzikhiya lesikulufu se-trapezoidal, esidinga ukunakwa ngesikhathi sokusebenzisa.

Umhlahlandlela womugqa: umhlahlandlela womugqa, owaziwa nangokuthi umgwaqo wesilayidi, umhlahlandlela womugqa, isilayidi esiwumugqa, ngezikhathi zokunyakaza okuphindaphindayo, unesilinganiso somthwalo esiphezulu kunamabheringi aqondile, kuyilapho singathwala itorque ethile, singaba esimweni somthwalo omkhulu ukuze sifinyelele ukunemba okuphezulu komugqa ukunyakaza, ngaphezu kwezinye izikhathi zokunemba okuphansi kungashintshwa futhi kufakwe ibhokisi elinomugqa, kodwa kufanele kuqashelwe ukuthi kumthamo we-torque kanye nomthamo wokulinganisa ukulayisha Ngokwegayidi empofu kuneyomugqa.

Iphrofayili ye-aluminium alloy module: i-module aluminium alloy profile sliding table ukubukeka okuhle, ukuklama okunengqondo, ukuqina okuhle, ukusebenza okuthembekile, izindleko zokukhiqiza eziphansi zivame ukusetshenziswa emishinini ye-automation yezimboni, ngokuqeda ukuhlanganiswa ku-module rigidity, ukuguqulwa okushisayo kuncane, ukuqina kokuphakelayo kuphezulu, ngaleyo ndlela kuqinisekiswe ukunemba okuphezulu nokuzinza okuphezulu kokusebenza kumishini ye-automation.

Isihlalo sokusekela isikulufu sebhola: Isihlalo sokusekela isikulufu sebhola siyisihlalo sokusekela esithwele ukusekela ukuxhumana phakathi kwesikulufu kanye nenjini, isihlalo sokusekela sivame ukuhlukaniswa sibe: uhlangothi olungaguquki kanye neyunithi yokusekela, uhlangothi olungaguquki lweyunithi yokusekela lufakwe i-angular elungiswe ngaphambilini. ukuxhumana namabhola. Ikakhulukazi, ohlotsheni lwe-ultra-compact, ibhola elihlangene le-angular elihlangene eline-engeli yokuxhumana engu-45° ethuthukiswe izikulufu zebhola ezihlangene kakhulu isetshenziselwa ukuzuza ukusebenza okuzinzile kokujikeleza okuqinile nokunemba okuphezulu. Ama-deep groove ball bearings asetshenziswa kuyunithi yokusekela ohlangothini lokusekela. Ukuthwala kwangaphakathi kweyunithi yokusekela kugcwele inani elifanele le-lithium-based grease-based grease futhi livalwe nge-gasket ekhethekile yokuvala, okuvumela ukufakwa okuqondile nokusetshenziswa isikhathi eside. I-angular bear iyamukelwa uma kucatshangelwa ibhalansi yokuqina ngesikulufu sebhola, kanye nebhola lokuxhumana elingu-angular elinokuqina okuphezulu kanye ne-torque ephansi (i-contact angle 30°, inhlanganisela yamahhala) isetshenziswa. Futhi, iyunithi yokwesekwa kwe-ultra-compact ifakwe i-ultra-compact angular yebhola yokuxhumana eyenzelwe izikulufu zebhola ezihlangene. Lolu hlobo lokuthwala lune-engeli yokuxhumana engu-45°, ububanzi bebhola elincane kanye nenani elikhulu lamabhola, futhi liyibhola lokuxhumana le-angular elincane kakhulu elinokuqina okuphezulu nokunemba okuphezulu, futhi lingathola ukusebenza kokubulala okuzinzile. Ukuma kweyunithi yokusekela kutholakala kuhlobo lwe-angular nochungechunge lohlobo oluyindilinga, olungakhethwa ngokuya ngohlelo lokusebenza. Encane futhi kulula ukuyifaka, iyunithi yokusekela iklanyelwe ngosayizi omncane ocabangela isikhala esizungeze ukufakwa. Ngesikhathi esifanayo, ama-bearings angaphambi kokucindezela angafakwa ngqo ngemva kokulethwa, ukunciphisa isikhathi somhlangano kanye nokuthuthukisa ukunemba komhlangano. Yiqiniso, uma kudingekile ukulondoloza umklamo wezindleko, ungenza futhi izingxenye zakho ezingezona ezijwayelekile ezithwala izindlu, ngokuhlanganiswa kwe-outsourcing okuhlanganisa ibe iyunithi yokusekela, isicelo se-batch sinenzuzo kakhulu ngokwezindleko.

Ukuhlanganisa: Ukuhlanganisa kusetshenziselwa ukuxhuma ama-shafts amabili ndawonye ukuze kudluliswe ukunyakaza kanye ne-torque, umshini uyayeka ukugijima ukuze uhlanganise noma uhlukanise idivayisi. Amashafu amabili ahlanganiswe ukuhlanganisa ngokuvamile awaqinisekiswanga ukuthi aqondaniswe ngokuqinile ngenxa yamaphutha okukhiqiza nawokufaka, ukuwohloka ngemva kokuthwala, kanye nomthelela wokushintsha kwezinga lokushisa, njll., kodwa kunezinga elithile lokufuduka okuhlobene. Lokhu kudinga idizayini yokuhlanganisa ukuthi ithathe izinyathelo ezihlukahlukene ezihlukene kusukela esakhiweni, ukuze ibe nokusebenza okuzivumelanisa nohlu oluthile lokugudluzwa okuhlobene. Ukuhlanganisa okuvame ukusetshenziswa ku-actuator yomugqa wemishini engajwayelekile ukuhlanganisa okuvumelana nezimo, futhi izinhlobo ezivamile ukuhlangana kwegroove, ukuhlanganisa ama-slide esiphambano, ukuhlanganisa iplamu, ukuhlanganisa i-diaphragm.

Ungakhetha kanjani i-coupling ye-actuator yomugqa:

Ukuhlanganisa okujwayelekile kokuzenzakalela okungajwayelekile.

Uma i-zero backlash idingeka, khetha uhlobo lwe-diaphragm noma uhlobo lwe-groove.

Lapho ukuhanjiswa kwetorque ephezulu kuyadingeka, khetha uhlobo lwe-diaphragm, umumo wesiphambano, umumo we-plummer.

Ama-Servo motors ahlome kakhulu uhlobo lwe-diaphragm, ama-stepper motors akhethwa kakhulu uhlobo lwe-groove.

Okumise okwesiphambano okuvamise ukusetshenziswa kusilinda noma ezenzakalweni zezimoto ezisongayo, ukusebenza okunembayo kungaphansi kancane (hhayi izidingo eziphezulu).

Nciphisa inzwa

Inzwa yomkhawulo ku-actuator yomugqa ngokuvamile izosebenzisa i-slot yohlobo lwe-photoelectric switch, i-slot uhlobo lwe-photoelectric switch empeleni iwuhlobo lokushintshwa kwe-photoelectric, ebizwa nangokuthi i-U-type photoelectric switch, iyimikhiqizo kagesi yokungeniswa kwe-infrared, ngeshubhu le-infrared transmitter kanye ne-infrared. inhlanganisela yeshubhu eyamukelayo, kanye nobubanzi be-slot ukunquma amandla emodeli yokwamukela ukungeniswa kanye nebanga lesiginali eyamukelwe ukuze ikhanye njengemaphakathi, ngokukhanya kwe-infrared phakathi komzimba okhanyayo nomzimba owamukela ukukhanya. i-medium, kanye nokukhanya kwe-infrared phakathi kwe-emitter nomamukeli kuyamukelwa futhi kuguqulwe ukuze kubonakale indawo yento. Iswishi yezithombe zikagesi ofakwe endaweni efanayo ayithinteki, ayiphoqwanga wumzimba wokuhlonza, kanye nebanga elide lokutholwa, ukunemba kokutholwa kwebanga elide (amamitha angamashumi amabili) kungathola izinto ezincane ezibanzi kakhulu zezinhlelo zokusebenza.

2. Izinzuzo nezinkinga ze-actuator yebhola

Uma kuncane ukuhola kwe-actuator ewumugqa, lapho ukuphonswa kwenjini ye-servo kukhulu kuya phezulu, ngokuvamile kuba kuncane ukuhola kwe-actuator ewumugqa, kulapho ukuhlohla kukhulu. Ngokuvamile esetshenziswa embonini yamandla amakhulu nomthwalo, njenge-servo emandleni angu-100W okulinganiselwe u-0.32N ngokusebenzisa isikulufu esiholayo esingu-5mm sebhola kungakhiqiza cishe u-320N thrust.

Ukusetshenziswa okujwayelekile kwe-axis ye-Z ngokuvamile kuvamise ukuba yi-actuator ye-screw linear, i-screw linear actuator kukhona esinye isici senzuzo ukunemba kwayo okuphezulu uma kuqhathaniswa nezinye izindlela zokudlulisela, i-actuator yomugqa evamile ephinda ukunemba kokubeka indawo ± 0.005 a ± 0.02mm, ngokuya ngokwangempela. izidingo zokukhiqizwa kwekhasimende, ngenxa ye-screw linear actuator etholwe isikulufu sebhola ingxenye encane yemikhawulo, isikulufu esijwayelekile se-actuator stroke are Ngeke ibe yinde kakhulu, 1/50 yobubanzi/ingqikithi yobude inani eliphezulu, ukulawula ngaphakathi kwalobu bubanzi, ngaphezu kobude bekesi dinga ukunciphisa isivinini sokugijima ngokumaphakathi. Ngaphezu kobude besilinganiso esincane se-actuator ngokusebenzisa i-servo motor high-speed rotation, i-resonance ye-filament izokhiqiza ukuchezuka kokudlidliza okubangelwa umsindo omkhulu nobungozi, ukuhlanganiswa kwe-ball screw kusekelwa kuzo zombili iziphetho, i-filament yinde kakhulu ngeke. kubangela kuphela ukuhlangana kalula ukuxegisa, kukhona ukunemba actuator, impilo yesevisi ukwehla. Thatha i-Taiwan ku-activator ye-KK esiliva njengesibonelo, i-resonance ingase yenzeke lapho i-stroke ephumelelayo idlula u-800mm, futhi isivinini esiphezulu kufanele sehliswe ngo-15% lapho ukushaya kukhuphuka ngo-100mm ngakunye.

3. Ukusetshenziswa kwe-screw actuator yebhola

I-motor ten linear actuator mechanism inesenzo esibushelelezi, ukunemba okuhle nokusebenza kokulawula (ingakwazi ukuma ngokuqondile kunoma iyiphi indawo ngaphakathi kwe-stroke), futhi isivinini sokugijima sinqunywa isivinini semoto kanye ne-screw pitch kanye nomklamo we-actuator, okungaphezulu. ilungele izikhathi zokushaywa unhlangothi ezincane nezimaphakathi, futhi iyindlela yomshini esetshenziswa amarobhothi amaningi alandelanayo. Embonini ye-automation imishini isetshenziswa kakhulu ku-semiconductor, LCD, PCB, medical, laser, 3C electronics, amandla amasha, izimoto nezinye izinhlobo zemishini ezishintshayo.

4. Incazelo yamapharamitha ahlobene we-screw actuator

Phinda ukunemba kokuma: Isho izinga lokuvumelana kwemiphumela eqhubekayo etholwe ngokusebenzisa okukhiphayo okufanayo ku-actuator efanayo nokuqedela ukubeka okuphindaphindiwe izikhathi ezimbalwa. Ukuphinda ukunemba kokumisa kuthonywa izici zesistimu ye-servo, ukucaciswa kanye nokuqina kwesistimu yokuphakelayo nezici zokungqubuzana. Ngokuvamile, ukunemba kokuma okuphindayo kuyiphutha lethuba elinokusabalalisa okuvamile, okuthinta ukuvumelana kokunyakaza okuningi kwe-actuator futhi kuyinkomba yokusebenza ebaluleke kakhulu.

Umhlahlandlela we-Ballscrew: Ibhekisela ekuphakameni kwentambo yesikulufu kusethi ye-screw die, futhi imele ibanga eliwumugqa (ngokuvamile ngo-mm: mm) lapho inadi liqhubekela phambili entanjeni ekuphendukeni ngakunye kwesikulufu.

Isivinini esiphezulu: isho isivinini esiphezulu somugqa esingafinyelelwa yi-actuator enobude obuhlukene bomhlahlandlela

Isisindo esiphezulu esiphathekayo: isisindo esiphezulu esingalayishwa yingxenye ehambayo ye-actuator, izindlela zokufaka ezihlukene zizoba namandla ahlukene

I-thrust elinganiselwe: I-thrust elinganiselwe engafinyelelwa lapho i-actuator isetshenziswa njengendlela yokududula.

Ukushaya okujwayelekile, isikhawu: Inzuzo yokuthengwa kwe-modular ukuthi ukukhethwa kuyashesha futhi kusesitokweni. Okubi ukuthi i-stroke isezingeni. Nakuba kungenzeka uku-oda osayizi abakhethekile nomkhiqizi, izinga linikezwa umenzi, ngakho-ke ukushaywa okujwayelekile kubhekisela kumodeli yesitoko somkhiqizi, futhi isikhawu siwumehluko phakathi kokushaywa okujwayelekile okuhlukile, ngokuvamile kusukela ku-stroke enkulu njengomkhawulo omkhulu. inani, phansi ngochungechunge lomehluko olinganayo. Isibonelo, uma i-stroke evamile ingu-100-1050mm futhi isikhawu singu-50mm, khona-ke ukushaywa okujwayelekile kwemodeli yesitoko kungu-100/150/200/250/300/350...1000/1050mm.

5. Inqubo yokukhetha ye-actuator ewumugqa

Nquma uhlobo lwe-actuator ngokuya ngezimo zokusebenza zohlelo lokusebenza lokuklama: isilinda, isikulufu, ibhande lesikhathi, i-rack ne-pinion, i-linear motor actuator, njll.

Bala futhi uqinisekise ukunemba kokuma okuphindayo kwe-actuator: qhathanisa ukunemba kokuma okuphindayo kwesidingo kanye nokunemba kokuma okuphindayo kwe-actuator, bese ukhetha i-actuator yokunemba efanele.

Bala isivinini sokugijima somugqa esiphezulu se-actuator bese unquma ububanzi bomhlahlandlela: Bala isivinini sokusebenza sezimo zohlelo lokusebenza oluklanyelwe, khetha i-actuator efanelekile ngesivinini esiphezulu se-actuator, bese unquma usayizi webanga lomhlahlandlela we-actuator.

Nquma indlela yokufaka kanye nesisindo somthwalo esiphezulu: Bala isisindo somthwalo kanye ne-torque ngokwendlela yokufaka.

Bala ukushaywa kwesidingo kanye ne-stroke evamile ye-actuator: Qondanisa ukushaywa okujwayelekile kwe-actuator ngokuya nge-stroke elinganiselwe yangempela.

Qinisekisa i-actuator ngohlobo lwemoto kanye nezinsiza: noma ngabe injini ibhuleki, ifomu lesifaki khodi, kanye nohlobo lwemoto.

Izici nokusetshenziswa kwe-actuator ye-KK

6. Incazelo yemojuli ye-KK

Imojula ye-KK iwumkhiqizo wohlelo olusezingeni eliphezulu osuselwe kumojula yomugqa wesikulufu sebhola, eyaziwa nangokuthi irobhothi le-axis eyodwa, okuyinkundla ehambayo eshayelwa yinjini, ehlanganisa isikulufu sebhola kanye nomhlahlandlela wesilayidi esiwumugqa ongu-U, isihlalo saso esislayidayo zombili. inadi elishayelayo lesikulufu sebhola kanye nesilayidi somhlahlandlela se-linear strain gauge, nesando senziwa ngesikulufu sebhola eliphansi ukuze kufezwe ukunemba okuphezulu.

7. Izici zemojuli ye-KK

Idizayini enemisebenzi eminingi: Ukuhlanganisa isikulufu sebhola sokushayela kanye ne-U-track yomhlahlandlela, sinikeza ukunyakaza okuqondile okuqondile. Ingasetshenziswa futhi ngezesekeli zemisebenzi eminingi. Kulula kakhulu ukwethula idizayini yohlelo lokusebenza enezinjongo eziningi, futhi ingafinyelela isidingo sokudluliswa okunembayo okuphezulu.

Usayizi omncane nesisindo esincane: I-U-track ingasetshenziswa njengethrekhi yomhlahlandlela kanye nesakhiwo seplathifomu ukuze kwehliswe kakhulu ivolumu yokufaka, futhi indlela yesici esilinganiselwe isetshenziselwa ukuklama isakhiwo esithuthukisiwe ukuze kutholwe isilinganiso esingcono kakhulu sokuqina nesisindo. Amandla e-torque kanye ne-inertia ephansi yokunyakaza kokumisa kahle kunganciphisa ukusetshenziswa kwamandla.

Ukunemba okuphezulu nokuqina okuphezulu: Ukuhlaziywa kwe-deformation yesikhundla sokuxhumana sebhola lensimbi ngomthwalo ohlangothini ngalunye kubonisa ukuthi le module eqondile yomugqa inezici zokunemba okuphezulu nokuqina okuphezulu. Idizayini yesakhiwo ethuthukisiwe ngendlela yesici esilinganiselwe ukuze uthole ukuqina okuhle kakhulu nesilinganiso sesisindo.

Kulula ukuhlola futhi ifakwe: kulula ukuhlola imisebenzi yokunemba kokubeka, ukubeka kabusha ukukhiqizwa, ukuhambisana kohambo kanye ne-torque yokuqala.

Kulula ukuhlanganisa nokunakekela: Umhlangano ungaqedwa ngaphandle kwesidingo sabasebenzi abanekhono. Ivikela uthuli futhi igcoba kahle, kulula ukuyinakekela futhi iphinde isetshenziswe ngemva kokuba umshini ulahliwe.

Ukuhlukahluka kwemikhiqizo, kungahambisana nesidingo sokukhetha:

Imodi yeDrayivu: ingahlukaniswa ibe isikulufu sebhola, ibhande le-synchronous

Amandla emoto: ozikhethela i-servo motor, noma i-stepper motor

Ukuxhumana kwezimoto: ngqo, phansi, ngaphakathi, kwesokunxele, kwesokudla, kuye ngokusetshenziswa kwendawo

I-stroke esebenzayo: 100-2000mm (ngokomkhawulo wejubane lesikulufa)

Ukwenza ngokwezifiso kungenziwa ngokuya ngezidingo zekhasimende: ucezu olulodwa noma inhlanganisela yomklamo okhethekile nokwakhiwa, i-eksisi eyodwa ingahlanganiswa ibe ukusetshenziswa kwe-multi-eksisi

8. Izinzuzo zemojuli ye-KK uma iqhathaniswa nemojuli yesikulufu esijwayelekile

Kulula ukuklama nokufaka, usayizi omncane nesisindo esincane

Ukuqina okuphezulu nokunemba okuphezulu (kufika ku-±0.003m)

Ifakwe ngokugcwele, ifaneleka kakhulu ukwakheka kwemodular

Kodwa kuyabiza futhi kuyabiza

9. Ukuhlelwa kwemojuli yerobhothi ye-axis eyodwa

Amamojula erobhothi e-axis eyodwa ahlukaniswa ngokwezinhlelo zokusebenza ezahlukahlukene njenge

I-KK (ukunemba okuphezulu)

SK (kuthule)

I-KC (i-integrated lightweight)

KA (lightweight)

I-KS (uthuli oluphezulu)

KU (high rigidity high dustproof)

I-KE (i-dustproof elula)

10. Ukukhetha izesekeli zemojuli ye-KK

Ukuze kuhambisane nezidingo ezihlukene zokusetshenziswa, amamojula e-KK ayatholakala futhi nekhava ye-aluminium, i-telescopic sheath (ikhava yesitho), i-flange yokuxhumeka kwemoto, kanye nokushintshwa komkhawulo.

Isembozo se-Aluminium ne-telescopic sheath (ikhava yesitho): ingavimbela izinto zangaphandle nokungcola ekungeneni kumojula ye-KK futhi kuthinte impilo yesevisi, ukunemba nokushelela.

I-flange yokuxhumeka kwezimoto: ingakhiya izinhlobo ezahlukene zamamotho kumojula ye-KK.

Ukushintsha komkhawulo: Ihlinzeka ngemikhawulo yokuphepha yokuma kwama-slide, indawo yokuqala futhi ivimbele isilayidi ukuthi singeqi ekuhambeni.

11. Izinhlelo zokusebenza zemojula ye-KK

Imojula ye-KK isetshenziswa ezinhlobonhlobo zemishini ezishintshayo. Ivamise ukusetshenziswa kule mishini elandelayo: umshini wokushisela ithini othomathikhi, umshini wokukhiya isikulufu, ukukhethwa kwebhokisi lezingxenye zeshalofu, imishini encane yokufakelwa kabusha, umshini wokumboza, ukukhethwa kwezingxenye kanye nokubamba indawo, ukunyakaza kwelensi yeCCD, umshini wokupenda othomathikhi, ukulayisha nokuthulula okuzenzakalelayo. idivayisi, umshini wokusika, izinto zokukhiqiza izingxenye ze-elekthronikhi, ulayini wokuhlanganisa omncane, umshini wokunyathelisa omncane, umshini wokushisela indawo, okokusebenza kokulambisa okuzenzakalelayo, umshini wokulebula othomathikhi, ukugcwalisa uketshezi nokukhipha, izingxenye nezingxenye zokusabalalisa, Ukugcwaliswa nokusabalalisa uketshezi, imishini yokuhlola izingxenye, umugqa wokukhiqiza. ukuqedwa kwe-workpiece, umshini wokugcwalisa izinto ezibonakalayo, umshini wokupakisha, umshini wokuqopha, ukufuduka kwebhande elihambisayo, imishini yokuhlanza i-workpiece, njll.

Isikhathi sokuthumela: Jun-18-2020