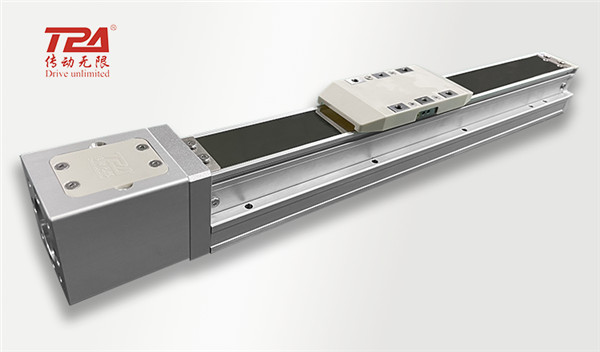

Ibhola Screw uhlobo lwe-actuator ye-linear ikakhulu iqulathe isikrufu sebhola, isikhokelo somgca, iprofayili ye-aluminium alloy, isiseko senkxaso ye-screw, ukudibanisa, i-motor, i-sensor yomda, njl.

Ibhola Screw: Ibhola Screw ilungele ukuguqula intshukumo ejikelezayo ibe sisindululo somgca, okanye intshukumo yomgama ibe yintshukumo ejikelezayo. Isikrufu sebhola siquka isikrufu, indongomane kunye nebhola. Umsebenzi wayo kukuguqula intshukumo ejikelezayo ibe sisinyanzelo somgca, esisisongezo esongezelelweyo kunye nophuhliso lwesijija sebhola. Ngenxa yokuchasana kwayo okuncinci, isikrufu sebhola sisetyenziswa ngokubanzi kwizixhobo ezahlukeneyo zemizi-mveliso kunye nezixhobo ezichanekileyo. Ukuchaneka okuphezulu kokuhamba komgca kunokufezekiswa phantsi komthwalo ophezulu. Nangona kunjalo, isikrufu sebhola asinaso isakhono sokuzivalela se-trapezoidal screw, esifuna ingqwalasela kwinkqubo yokusetyenziswa.

Isikhokelo somgca: Isikhokelo somgca, ekwaziwa ngokuba sisilayidi, isikhokelo somgca, isilayidi somgca, kwiziganeko zentshukumo eziphindaphindayo, inomlinganiselo ophezulu womthwalo kuneebheringi zomgca, ngelixa unokuthwala itorque ethile, unokuba kwimeko yomthwalo ophezulu ukufezekisa ukuchaneka okuphezulu. isindululo, ukongeza kwezinye iimeko ezichanekileyo ezisezantsi zinokutshintshwa kwakhona ngeebheringi zebhokisi, kodwa kufuneka kuqatshelwe ukuba kwitorque kunye nomthamo wokukala umthwalo Ngokubhekiselele kwisikhokelo esihlwempuzekileyo kunelayini.

Imodyuli ye-aluminium alloy profile: imodyuli ye-aluminium alloy iprofayili ye-sliding table inkangeleko entle, uyilo olufanelekileyo, ukuqina okuhle, ukusebenza okuthembekileyo, ixabiso eliphantsi lemveliso lihlala lisetyenziswa kwizixhobo zomatshini wokwenza izinto ezizenzekelayo, ngokugqibezela ukudibanisa kwimodyuli yokuqina, ukuguqulwa kwe-thermal kuncinci, ukondla uzinzo kuphezulu, ngaloo ndlela kuqinisekisa. ukuchaneka okuphezulu kunye nokuzinza okuphezulu kokusebenza kwizixhobo ezizenzekelayo.

Isihlalo senkxaso yebhola: Isihlalo sokuxhasa i-ball screw sisihlalo sokuxhasa ukuxhasa uxhulumaniso phakathi kwe-screw kunye ne-motor, isihlalo senkxaso sahlulwe ngokubanzi sibe: icala elisisigxina kunye neyunithi yenkxaso, icala elisisigxina leyunithi yenkxaso lixhotyiswe ngoxinzelelo lwangaphambili oluhlengahlengisiweyo. iibheringi zebhola zoqhagamshelwano. Ngokukodwa, kwi-ultra-compact type, i-ultra-compact angular contact ball ephethe i-angle yoqhagamshelwano ye-45 ° ephuhliswe kwi-screws ye-ultra-compact ibhola isetyenziselwa ukufezekisa ukusebenza okujikelezayo okuzinzileyo kunye nokuqina okuphezulu kunye nokuchaneka okuphezulu. Iibhodi zebhola ze-groove ezinzulu zisetyenziswa kwiyunithi yenkxaso kwicala lokuxhasa. Ukuthwala kwangaphakathi kweyunithi yenkxaso izaliswe ngexabiso elifanelekileyo le-lithium isepha-based grease kwaye itywinwe nge-gasket ekhethekileyo yokutywinwa, evumela ukunyuka ngokuthe ngqo kunye nokusetyenziswa kwexesha elide. I-optimum bearing yamkelwa ngokuqwalasela ibhalansi yokuqina kunye ne-screw yebhola, kunye ne-angular yokudibanisa ibhola ephethe i-rigidity ephezulu kunye ne-torque ephantsi (i-contact angle 30 °, inhlanganisela yamahhala) isetyenziswa. Kwakhona, iyunithi yenkxaso ye-ultra-compact ixhotyiswe nge-ultra-compact ye-angular yoqhagamshelwano yebhola ephuhliswe izikrufu zebhola ze-ultra-compact. Olu hlobo lokuthwala lune-angle yokudibanisa i-45 °, i-angle encinci yebhola kunye nenani elikhulu leebhola, kwaye i-ultra-incinci yebhola yokudibanisa i-angular ene-rigidity ephezulu kunye nokuchaneka okuphezulu, kwaye inokufumana ukusebenza okuzinzile kokubulala. Ubume beyunithi yenkxaso ifumaneka kuhlobo lwe-angular kunye nohlobo olujikelezayo, olunokuthi lukhethwe ngokwesicelo. Incinci kwaye kulula ukuyifaka, iyunithi yenkxaso yenzelwe ubungakanani obuncinci obuthatha ingqalelo indawo ejikeleze ukufakela. Ngexesha elifanayo, iibheringi zangaphambi koxinzelelo zinokuthi zifakwe ngokuthe ngqo emva kokunikezelwa, ukunciphisa ixesha lokudibanisa kunye nokuphucula ukuchaneka kwendibano. Kakade ke, ukuba kuyimfuneko ukugcina uyilo lweendleko, unokwenza kwakhona iindawo zakho ezingezizo eziqhelekileyo ezithwala izindlu, kunye nokudibanisa ukukhupha ngaphandle kwiyunithi yenkxaso, isicelo sebhetshi sinenzuzo kakhulu ngokweendleko.

Ukudibanisa: Ukudibanisa kusetyenziselwa ukudibanisa i-shafts ezimbini kunye nokudlulisa intshukumo kunye ne-torque, umatshini uyeka ukubaleka ukujoyina okanye ukwahlula isixhobo. Iishafu ezimbini ezidityaniswe ludibaniso zihlala zingaqinisekiswanga ukuba zilungelelaniswe ngokungqongqo ngenxa yeempazamo zokwenziwa kunye nofakelo, i-deformation emva kokuthwala, kunye nefuthe lokutshintsha kobushushu, njl. njl., kodwa kukho inqanaba elithile lokufuduswa. Oku kufuna ukuba uyilo lokudibanisa ukuthatha amanyathelo ahlukeneyo ahlukeneyo ukusuka kwisakhiwo, ukwenzela ukuba kube nokusebenza ukulungelelanisa uluhlu oluthile lokufuduka. Ukudibanisa okuqhelekileyo kusetyenziswa kwisixhobo esingaqhelekanga se-actuator ye-linear yi-flexible coupling, kwaye iintlobo eziqhelekileyo zidibanisa i-groove, i-cross slide coupling, i-plum coupling, i-diaphragm coupling.

Unokukhetha njani ukudityaniswa kwe-actuator yomgca:

Ukudibanisa okuqhelekileyo kwi-automation engekho-standard.

Xa i-zero backlash ifunekayo, khetha uhlobo lwe-diaphragm okanye uhlobo lwe-groove.

Xa kufuneka ukuhanjiswa kwetorque ephezulu, khetha uhlobo lwe-diaphragm, imilo yomnqamlezo, imilo ye-plum.

Iinjini ze-Servo zixhotyiswe kakhulu ngohlobo lwe-diaphragm, iimotor ze-stepper zikhethwa kakhulu luhlobo lwegroove.

Ubume obunqamlezileyo obusetyenziswa ngokuqhelekileyo kwi-cylinder okanye kwiziganeko ezijikelezayo zeemoto, ukusebenza okuchanekileyo kungaphantsi kancinci (kungekhona iimfuno eziphezulu).

Isivamvo somda

Isivamvo somda kwi-actuator yomgca ngokubanzi siya kusebenzisa i-slot yohlobo lwe-photoelectric switch, i-slot type ye-photoelectric switch eneneni luhlobo lwe-photoelectric switch, ekwabizwa ngokuba yi-U-type photoelectric switch, yimveliso ye-infrared infrared photoelectric, yityhubhu yokudlulisa i-infrared kunye ne-infrared. Umdibaniso wetyhubhu yomamkeli, kunye nobubanzi beslot kukuqinisekisa amandla emodeli yokufumana induction kunye nomgama wesignali efunyenweyo ekukhanyeni njengokukhanya okuphakathi, ngokukhanya kwe-infrared phakathi komzimba okhanyayo kunye nomzimba owamkela ukukhanya. i-medium, kunye nokukhanya kwe-infrared phakathi kwe-emitter kunye nomamkeli ifunyenwe kwaye iguqulelwe ukuqaphela indawo yento. I-slotted photoelectric switch kwi-souwitch proximity efanayo ayidibanisi, ingaphantsi kokunyanzeliswa ngumzimba wokufumanisa, kunye nomgama omde wokufumanisa, ukukhangela umgama omde (iimitha ezininzi) ukuchaneka kokufumanisa kunokubona izinto ezincinci ezibanzi kakhulu zezicelo.

2. Ibhola Screw actuator inzuzo kunye nokungalungi

Okukhona kuncinci ukukhokela kwe-actuator yomgca, kokukhona ukutyhala kwemoto ye-servo ukuya kowona mgangatho uphezulu, ngokuqhelekileyo incinci isikhokelo se-actuator yomgca, kokukhona ukutyhala okukhulu. Ngokuqhelekileyo esetyenziswa kushishino lwamandla amakhulu kunye nomthwalo, njenge-servo kumandla i-100W elinganiselwe i-thrust 0.32N nge-lead 5mm ibhola screw inokuvelisa malunga ne-320N thrust.

Ukusetyenziswa ngokubanzi kwe-Z-axis ngokuqhelekileyo yibhola Screw linear actuator, ibhola Screw linear actuator kukho omnye umba we-advanteji kukuchaneka kwayo okuphezulu xa kuthelekiswa nezinye iindlela zothumelo, i-actuator yomgca ngokubanzi iphinda ukuchaneka kokubeka indawo ± 0.005 a ± 0.02mm, ngokweyona nyani Iimfuno zemveliso yomthengi, ngenxa yebhola Screw linear actuator efunyenweyo ibhola screw esibhityileyo umlinganiselo, ngokubanzi ibhola screw linear actuator stroke are Ayinakuba mde kakhulu, 1/50 yobubanzi/ubude bubonke lixabiso eliphezulu, ulawulo phakathi kolu luhlu, ngaphaya kobude betyala kufuneka ukunciphisa isantya sokubaleka ngokuphakathi. Ngaphezulu kobude be-slim ratio ye-actuator ngokujikeleza kwe-servo motor-high-speed rotation, i-resonance ye-filament iya kuvelisa i-vibration deflection ebangelwa yingxolo enkulu kunye nobungozi, i-ball screw assembly ixhaswa kuzo zombini iziphelo, i-filament inde kakhulu ayiyi kuphela kubangela ukudibanisa lula ukukhulula, kukho ukuchaneka kwe-actuator, ubomi benkonzo buyancipha. Thatha iTaiwan kwi-actuator yesilivere ye-KK umzekelo, i-resonance ingenzeka xa i-stroke esebenzayo idlula i-800mm, kwaye isantya esiphezulu kufuneka sincitshiswe nge-15% xa i-stroke inyuka nge-100mm nganye.

3. Ukusetyenziswa kwe-screw actuator yebhola

Umtshini we-motor ten linear actuator inentshukumo egudileyo, ichanekile kwaye ilawula ukusebenza kakuhle (inokumisa ngokuchanekileyo nakweyiphi na indawo ngaphakathi kwesibetho), kwaye isantya sokubaleka simiselwa sisantya semoto kunye ne-screw pitch kunye noyilo lwe-actuator, engaphezulu. ilungele iziganeko ezincinci neziphakathi, kwaye ikwayindlela yomatshini esetyenziswa ziirobhothi ezininzi. Kwishishini le-automation izixhobo zisetyenziswa kakhulu kwi-semiconductor, i-LCD, i-PCB, unyango, i-laser, i-elektroniki ye-3C, amandla amatsha, iimoto kunye nezinye iintlobo zezixhobo ezizenzekelayo.

4. Inkcazo yeeparamitha ezinxulumene ne-screw actuator

Phinda ukuchaneka kokubeka: Ibhekisa kwiqondo lokungaguquguquki kweziphumo eziqhubekayo ezifunyenwe ngokusebenzisa isiphumo esifanayo kwi-actuator efanayo kunye nokugqiba ukubeka okuphindaphindiweyo amaxesha amaninzi. Ukuphindaphinda ukuchaneka kokumisa kuphenjelelwa ziimpawu zenkqubo ye-servo, ukucocwa kunye nokuqina kwenkqubo yokutya kunye neempawu zokukhuhlana. Ngokubanzi, ukuphinda ukuchaneka kokubekwa yimpazamo yethuba kunye nokusabalalisa okuqhelekileyo, okuchaphazela ukuhambelana kweentshukumo ezininzi ze-actuator kwaye sisalathiso esibaluleke kakhulu sokusebenza.

Ballscrew guide: Ibhekisa kwipitch yentambo yesikrufu kwiseti yesikrufu sokufa, kwaye ikwamele umgama womgama (ngokubanzi nge-mm: mm) ukuba i-nut iqhubela phambili kumsonto kwi-revolution nganye yesikrufu.

Esona santya siphezulu: ibhekisa kwisantya esiphezulu somgca esinokufikelelwa yi actuator enobude besikhokhelo obahlukeneyo

Ubunzima obuphathekayo obuphezulu: ubunzima obuninzi obunokulayishwa yinxalenye ehambayo ye-actuator, iindlela ezahlukeneyo zokufakela ziya kuba namandla ahlukeneyo

Ugxininiso olukalwe: Ithrasti elinganisiweyo enokuphunyezwa xa i-activator isetyenziswa njengendlela yokutyhala.

Ukubetha okuqhelekileyo, ikhefu: Inzuzo yokuthengwa kweemodyuli kukuba ukhetho lukhawuleza kwaye lusesitokhweni. Ukungalungi kukuba i-stroke isemgangathweni. Nangona kunokwenzeka uku-odola ubungakanani obukhethekileyo kunye nomenzi, umgangatho unikwe umenzi, ngoko ke i-stroke esemgangathweni ibhekisela kwimodeli yesitokhwe somenzi, kwaye ikhefu ngumahluko phakathi kwemivumbo ehlukeneyo eqhelekileyo, ngokuqhelekileyo ukusuka kwi-stroke ephezulu njengobuninzi. ixabiso, phantsi umahluko olinganayo uthotho. Ngokomzekelo, ukuba i-stroke esemgangathweni yi-100-1050mm kunye ne-interval yi-50mm, ngoko i-stroke ye-stock model yi-100/150/200/250/300/350...1000/1050mm.

5. Inkqubo yokukhetha i-actuator yomgca

Qinisekisa uhlobo lwe-activator ngokwemiqathango yokusebenza yesicelo soyilo: i-cylinder, screw, ibhanti lexesha, i-rack kunye ne-pinion, i-actuator yemoto ehambelanayo, njl.

Bala uze uqinisekise ukuchaneka kokuphinda-phinda kokubeka kwe-activator: thelekisa ukuphinda ukuchaneka kokubeka kwemfuno kunye nokuphinda ukuchaneka kokubeka kwe-activator, kwaye ukhethe i-actuator echanekileyo efanelekileyo.

Bala esona santya siphezulu somgama we-actuator kwaye umisele uluhlu lwesikhokelo: Bala isantya sokuqhuba semeko yesicelo esenziweyo, khetha i-actuator efanelekileyo ngesantya esiphezulu se-actuator, uze ugqibe ubungakanani boluhlu lwesikhokelo se-actuator.

Qinisekisa indlela yokufakela kunye nobunzima bomthwalo omkhulu: Bala ubunzima bomthwalo kunye netorque ngokwendlela yokufaka.

Bala i-stroke yemfuno kunye ne-standard stroke ye-actuator: Tshatisa i-stroke esemgangathweni ye-actuator ngokomlinganiselo oqikelelweyo we-stroke.

Qinisekisa i-actuator ngohlobo lwemoto kunye nezincedisi: nokuba imoto ibhulekiwe, ifom ye-encoder, kunye nohlobo lwemoto.

Iimpawu kunye nokusetyenziswa kwe-KK actuator

6. Inkcazo yemodyuli ye-KK

Imodyuli ye-KK yimveliso yomgangatho ophezulu wesicelo esekwe kwimodyuli yomgca webhola ekrwada, ekwaziwa ngokuba yirobhothi ye-axis enye, eyiqonga eliqhutywa yimoto, eliquka isikrufu sebhola kunye nesikhokelo sesilayidi esimilise u-U, esisitulo sokutyibilika zombini. i-nut yokuqhuba yebhola Screw kunye nesilayidi sesikhokelo se-linear strain gauge, kunye nehamile yenziwe ngesikrufu sebhola ephantsi ukuphumeza ukuchaneka okuphezulu.

7. Iimpawu zemodyuli ye-KK

Uyilo olunemisebenzi emininzi: Ukudibanisa isikrufu sebhola kwi-drive kunye ne-U-track yesikhokelo, inika intshukumo echanekileyo yomgca. Inokusetyenziswa kwakhona kunye nezixhobo ezininzi zokusebenza. Kulunge kakhulu ukwazisa uyilo lwesicelo seenjongo ezininzi, kwaye kunokufikelela kwimfuno yosasazo oluchanekileyo oluphezulu.

Ubungakanani obuncinci kunye nobunzima obulula: I-U-track ingasetyenziswa njengomzila wesikhokelo kwaye kunye nesakhiwo seqonga ukunciphisa kakhulu umthamo wofakelo, kwaye indlela ye-finite element isetyenziselwa ukuyila ulwakhiwo oluphuculweyo lokufumana owona bunzima kunye nobunzima. Amandla e-torque kunye ne-inertia ephantsi yentshukumo yokumisa egudileyo inokunciphisa ukusetyenziswa kwamandla.

Ukuchaneka okuphezulu kunye nokuqina okuphezulu: Uhlalutyo lwe-deformation yesikhundla soqhagamshelwano lwebhola yensimbi ngomthwalo kwicala ngalinye lubonisa ukuba le modyuli echanekileyo yomgca ineempawu zokuchaneka okuphezulu kunye nokuqina okuphezulu. Uyilo lolwakhiwo olulungiselelwe ngendlela enomda ukuze ufumane okona kuqina kunye nobunzima.

Kulula ukuvavanya kunye nezixhobo: kulula ukuvavanya imisebenzi yokuchaneka kokubeka, ukubeka ukuveliswa kwakhona, ukuhamba ngokuhambelana kunye nokuqalisa i-torque.

Kulula ukudibanisa kunye nokugcina: Indibano ingagqitywa ngaphandle kwesidingo sabasebenzi abanobuchule. Ilungele uthuli kunye nokuthambisa, kulula ukuyigcina kunye nokusetyenziswa kwakhona emva kokuba umatshini ulahliwe.

Ukwahluka kweemveliso, kunokuhambelana nesidingo sokukhetha:

Imowudi yokuqhuba: inokwahlulwa ibe yibhola, ibhanti ye-synchronous

Amandla emoto: ozikhethelayo servo motor, okanye stepper motor

Uqhagamshelo lweMoto: ngqo, ngaphantsi, ngaphakathi, ekhohlo, ekunene, kuxhomekeke kusetyenziso lwendawo

I-stroke esebenzayo: 100-2000mm (ngokomda wesantya sokujija)

Ukwenza ngokwezifiso kunokwenziwa ngokweemfuno zomthengi: isiqwenga esinye okanye indibaniselwano yoyilo olukhethekileyo kunye nokuveliswa, i-axis enye inokudityaniswa kusetyenziso lwe-multi-axis.

8. Izinto eziluncedo zemodyuli ye-KK xa kuthelekiswa nemodyuli yesikrufu eqhelekileyo

Kulula ukuyila kunye nokuyifaka, ubungakanani obuncinci kunye nobunzima obulula

Ukuqina okuphezulu kunye nokuchaneka okuphezulu (ukuya kuthi ga ku-±0.003m)

Ixhotyiswe ngokupheleleyo, eyona ifanelekileyo kuyilo lweemodyuli

Kodwa kuyabiza kwaye kuyabiza

9. Ukuhlelwa kwemodyuli yerobhothi ene-axis enye

Iimodyuli zerobhothi ezine-axis enye zihlelwa ngokwezicelo ezahlukeneyo njenge

I-KK (echaneke kakhulu)

SK (cwaka)

KC (integrated lightweight)

KA (khaphukhaphu)

KS (uthuli oluphezulu)

KU (high rigidity high dustproof)

I-KE (ilula uthuli)

10. Ukhetho lwemodyuli ye-KK

Ukuze ihambelane neemfuno zokusetyenziswa ezahlukeneyo, iimodyuli ze-KK zikwafumaneka kunye ne-aluminium ikhava, i-telescopic sheath (i-organ cover), i-motor connection flange, kunye nokutshintsha umda.

Isigqubuthelo se-aluminium kunye ne-telescopic sheath (i-organ cover): inokuthintela izinto zangaphandle kunye nokungcola ekungeneni kwimodyuli ye-KK kunye nokuchaphazela ubomi benkonzo, ukuchaneka kunye nokugudiswa.

Iflange yoqhagamshelo lweMoto: inokutshixa iintlobo ezahlukeneyo zeenjini kwimodyuli ye-KK.

Ukutshintsha umda: Ibonelela ngemida yokhuseleko yokubeka izilayidi, indawo yokuqala kunye nokuthintela isilayidi ekugqithiseni uhambo.

11. Usetyenziso lwemodyuli ye-KK

Imodyuli ye-KK isetyenziswa kuluhlu olubanzi lwezixhobo ezizenzekelayo. Isetyenziswa ngokuqhelekileyo kwezi zixhobo zilandelayo: umatshini we-tin welding oluzenzekelayo, umatshini wokutshixa i-screw, i-shelf part box pick and place, izixhobo ezincinci zokutshintshela, umatshini wokugquma, iindawo zokukhetha kunye nokuphatha indawo, ukunyakaza kwe-CCD lens, umatshini wokupeyinta ngokuzenzekelayo, ukulayisha ngokuzenzekelayo kunye nokukhulula. isixhobo, umatshini wokusika, izixhobo zokuvelisa i-elektroniki, umgca wokuhlanganisana omncinci, umatshini omncinci wokushicilela, umatshini wokuwelda, izixhobo zokubeka umphezulu, umatshini wokuleyibhela ngokuzenzekelayo, ukuzaliswa kolwelo kunye nokuhanjiswa, iinxalenye kunye namacandelo okuhambisa, ukuzaliswa kolwelo kunye nokuhanjiswa, izixhobo zokuvavanya izixhobo, umgca wokuvelisa. ukugqiba umsebenzi, isixhobo sokuzalisa izinto eziphathekayo, umatshini wokupakisha, umatshini wokukrola, ukuhanjiswa kwebhanti yokuhambisa, izixhobo zokucoca izixhobo zokusebenza, njl.

Ixesha lokuposa: Jun-18-2020