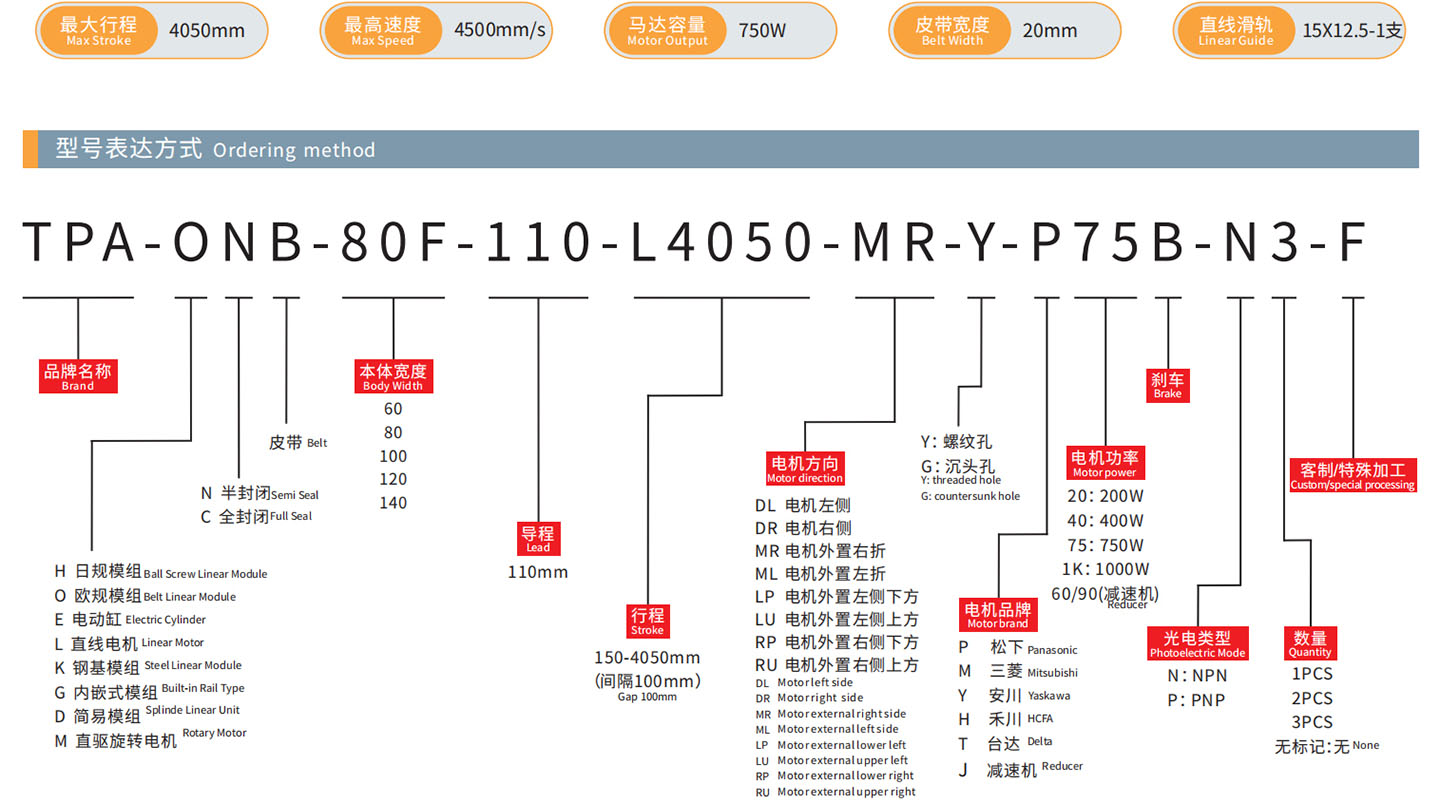

TPA ONB-F series belt driven linear module adopts an integrated design combining servo motor and belt with semi-closed design, which converts the rotary motion of the servo motor into linear motion, precisely controls the speed, position, and thrust of the slider, and realizes high precision automatic control.

The semi-closed belt-drives linear actuator, and the belt width is large and the profile is open. To some extent, the belt is used instead of the cover plate to prevent foreign objects from entering the module.

Features

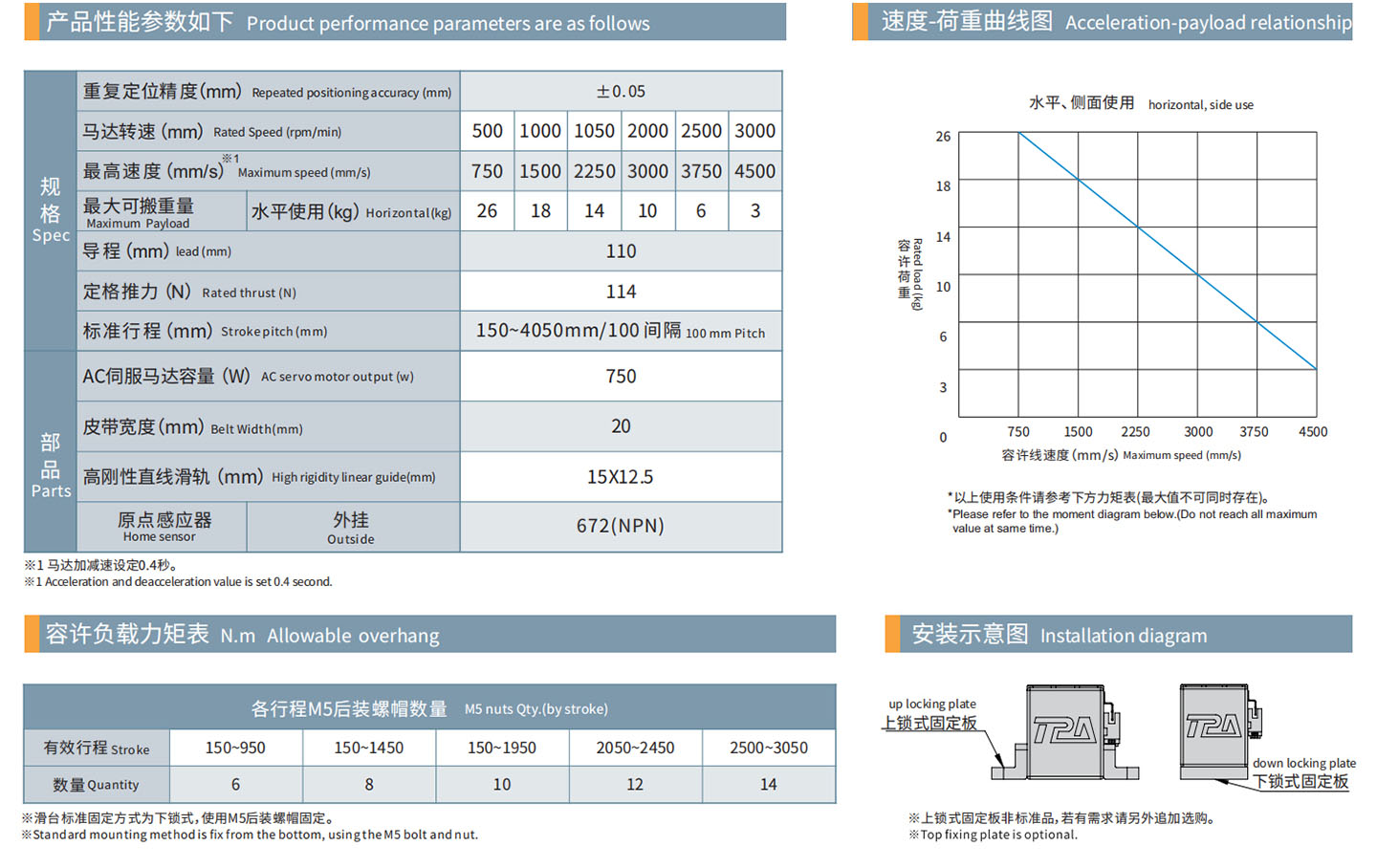

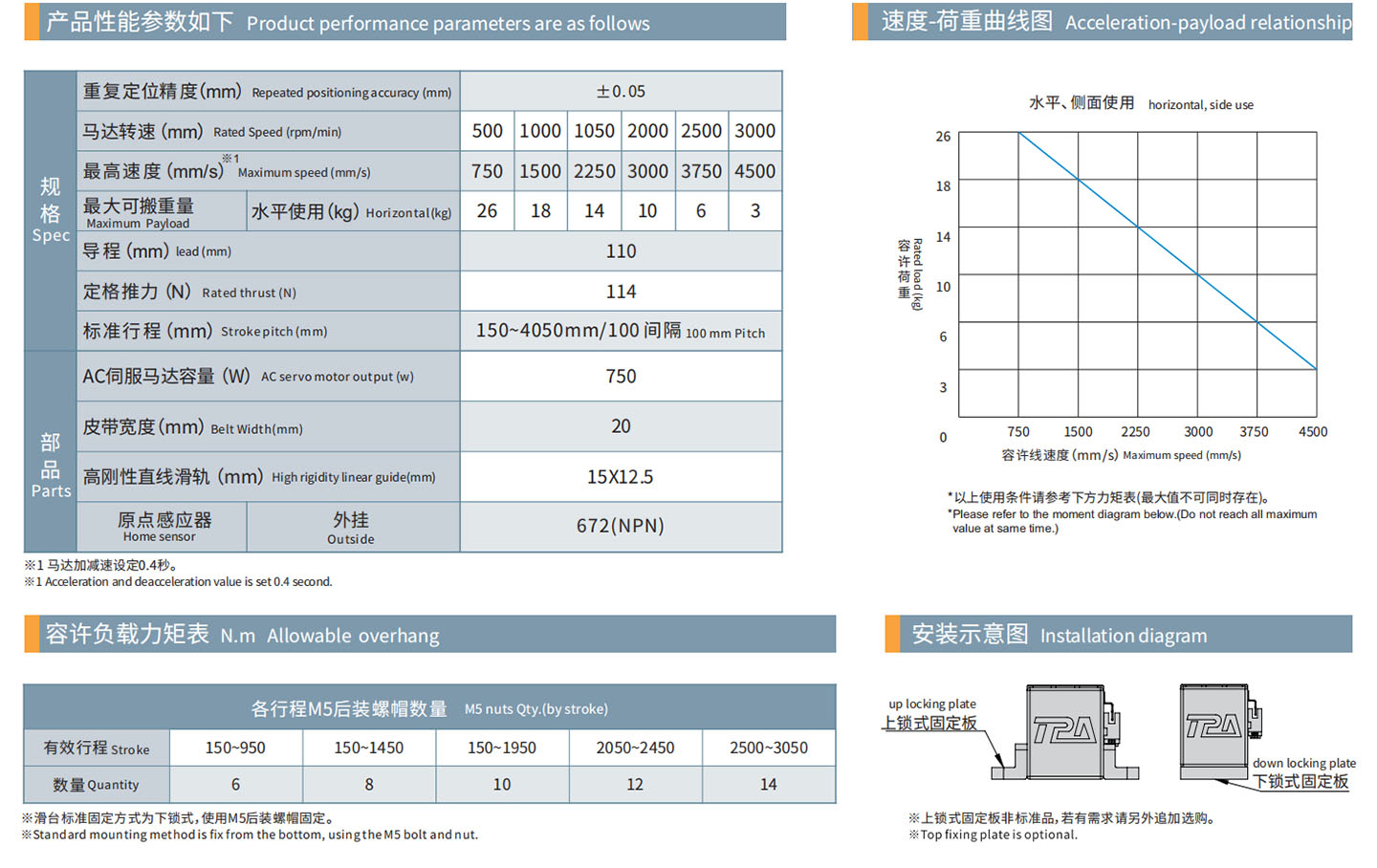

Repeated Positioning Accuracy: ±0.05mm

Max Payload(Horizontal): 230kg

Max Payload(Vertical): 90kg

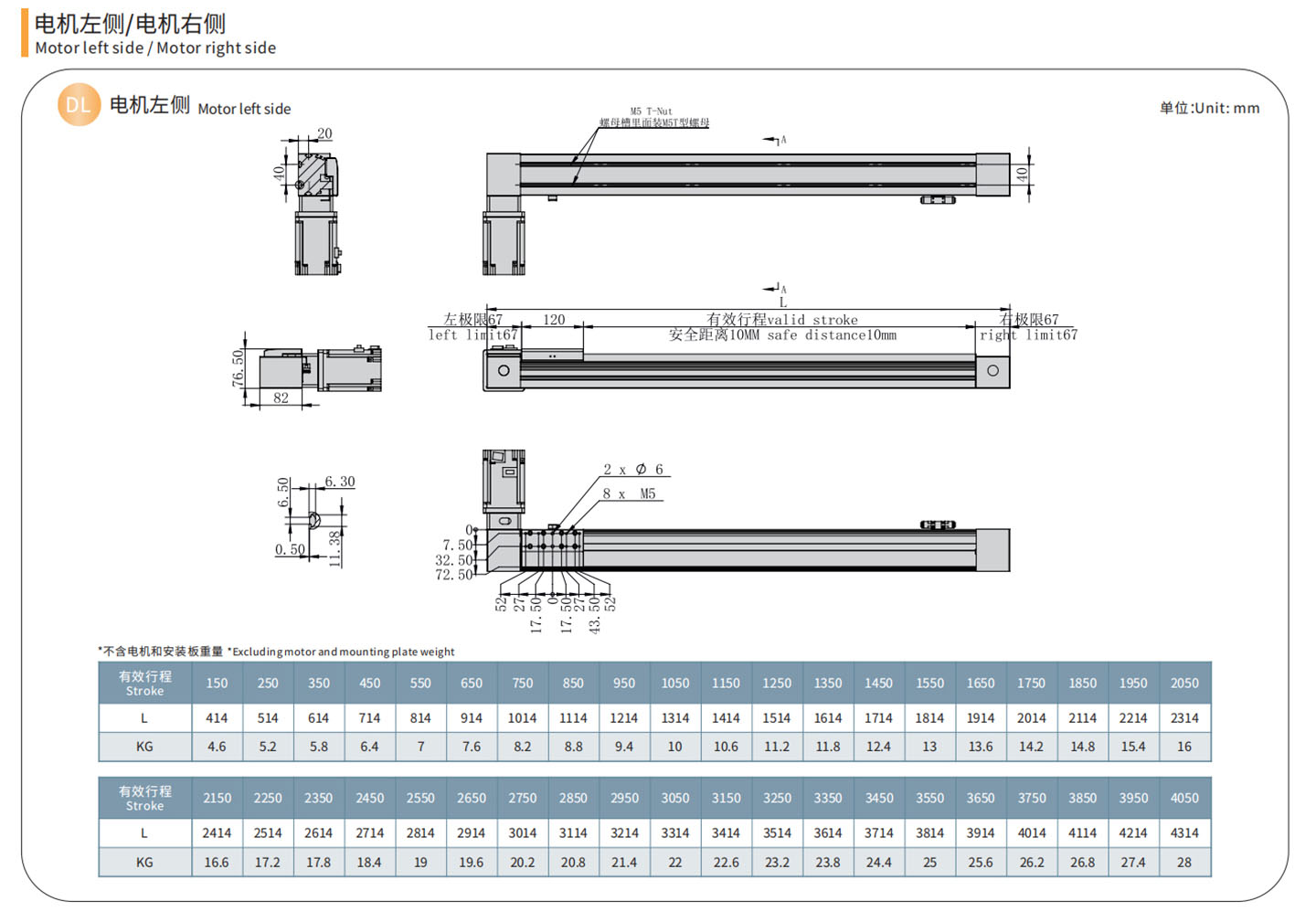

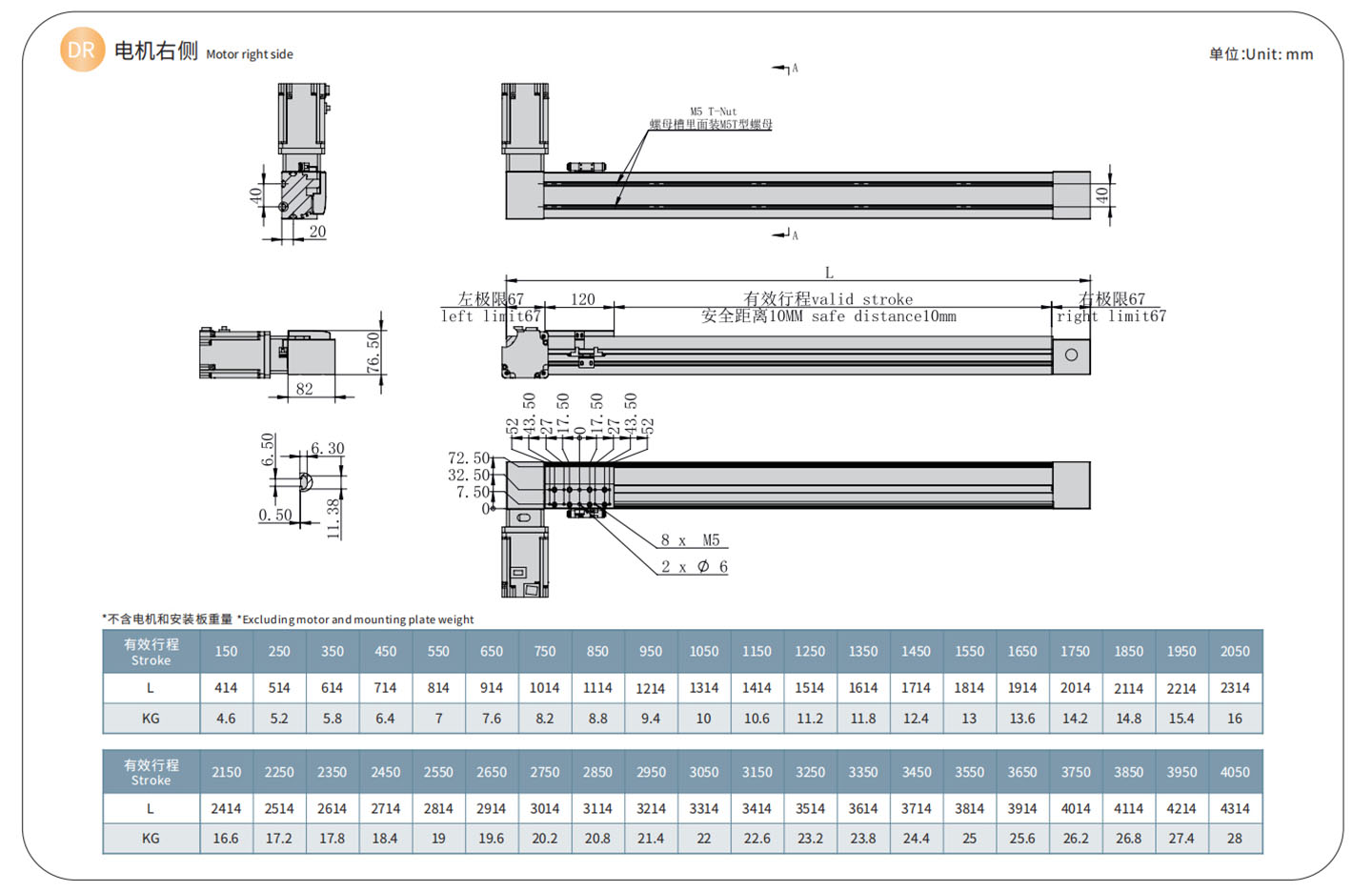

Stroke: 150 – 5050mm

Max Speed: 2300mm/s

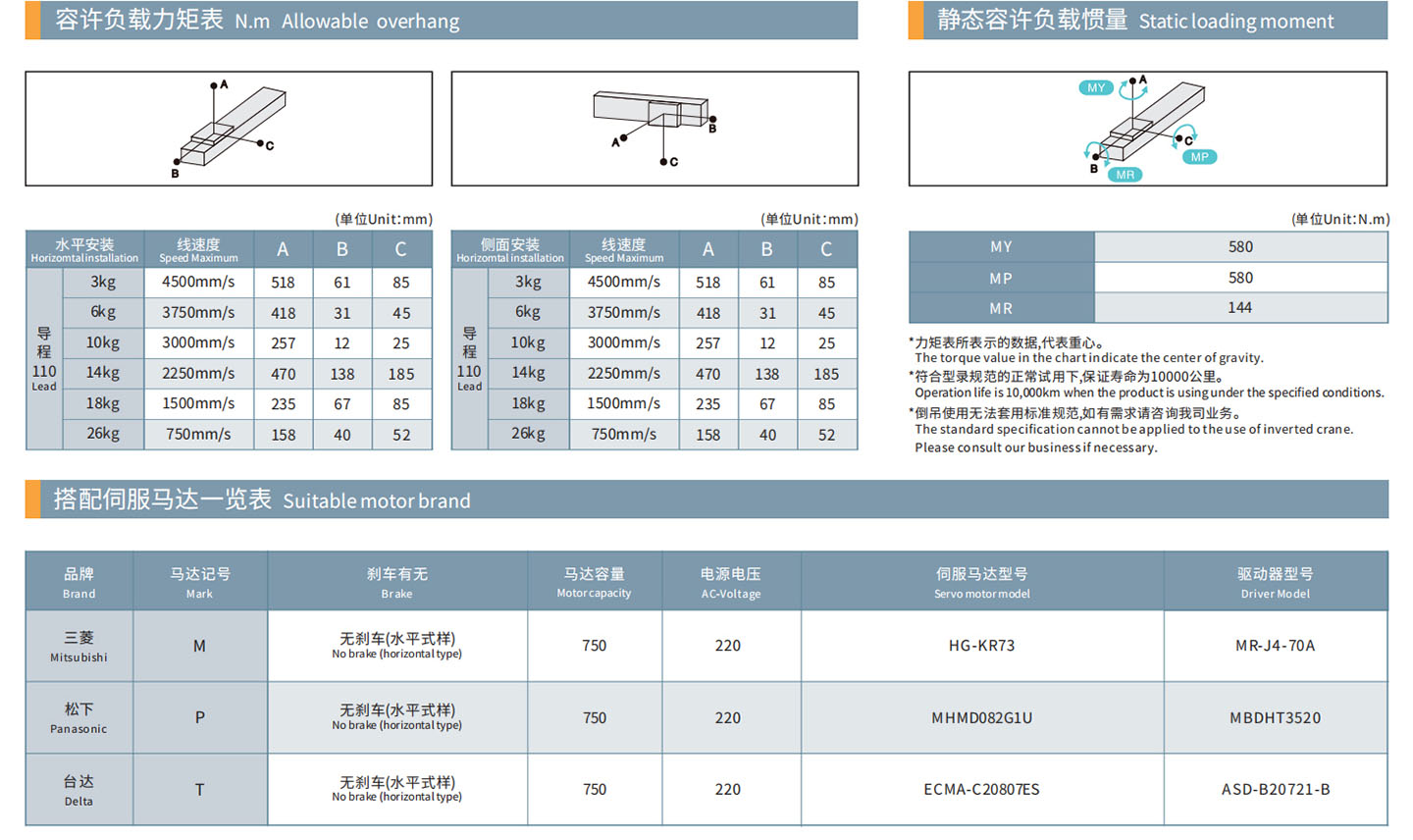

The profile design uses finite element stress analysis to simulate the rigidity and structural stability of the profile, reducing the volume and improving the load capacity.

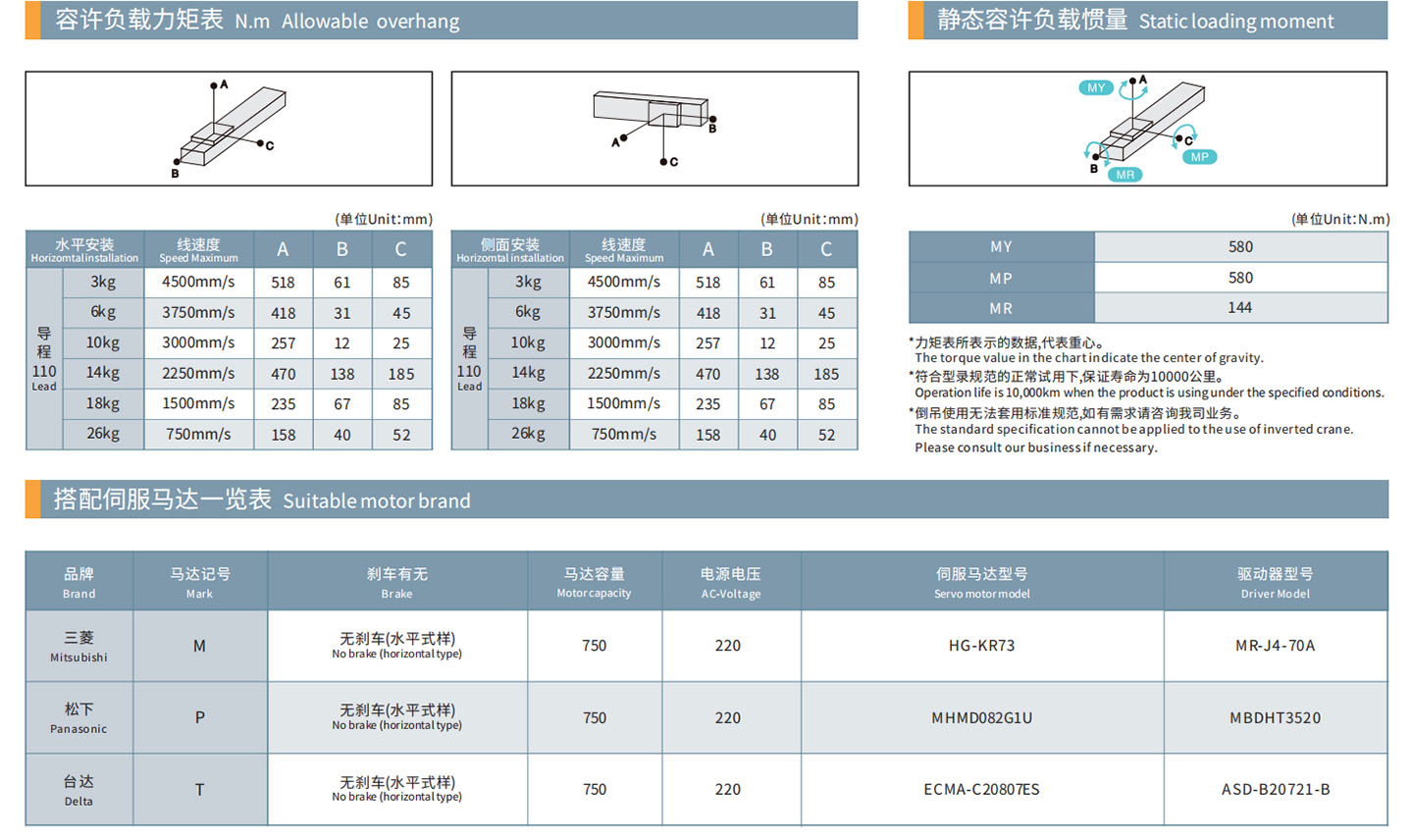

S5M and S8M series are used for the synchronous belt and synchronous wheel, with overload, super torque and super precision. The customer chooses circular arc tooth type for vertical use, T-shaped tooth type for horizontal high-speed running, and rubber open belt for high temperature, which can meet various applications of customers.

When the vertical and side loads are large, you can choose to install an auxiliary guide rail on the side of the profile to strengthen the lateral moment of the module, and can also increase the strength of the module and the stability of the module in use and operation.

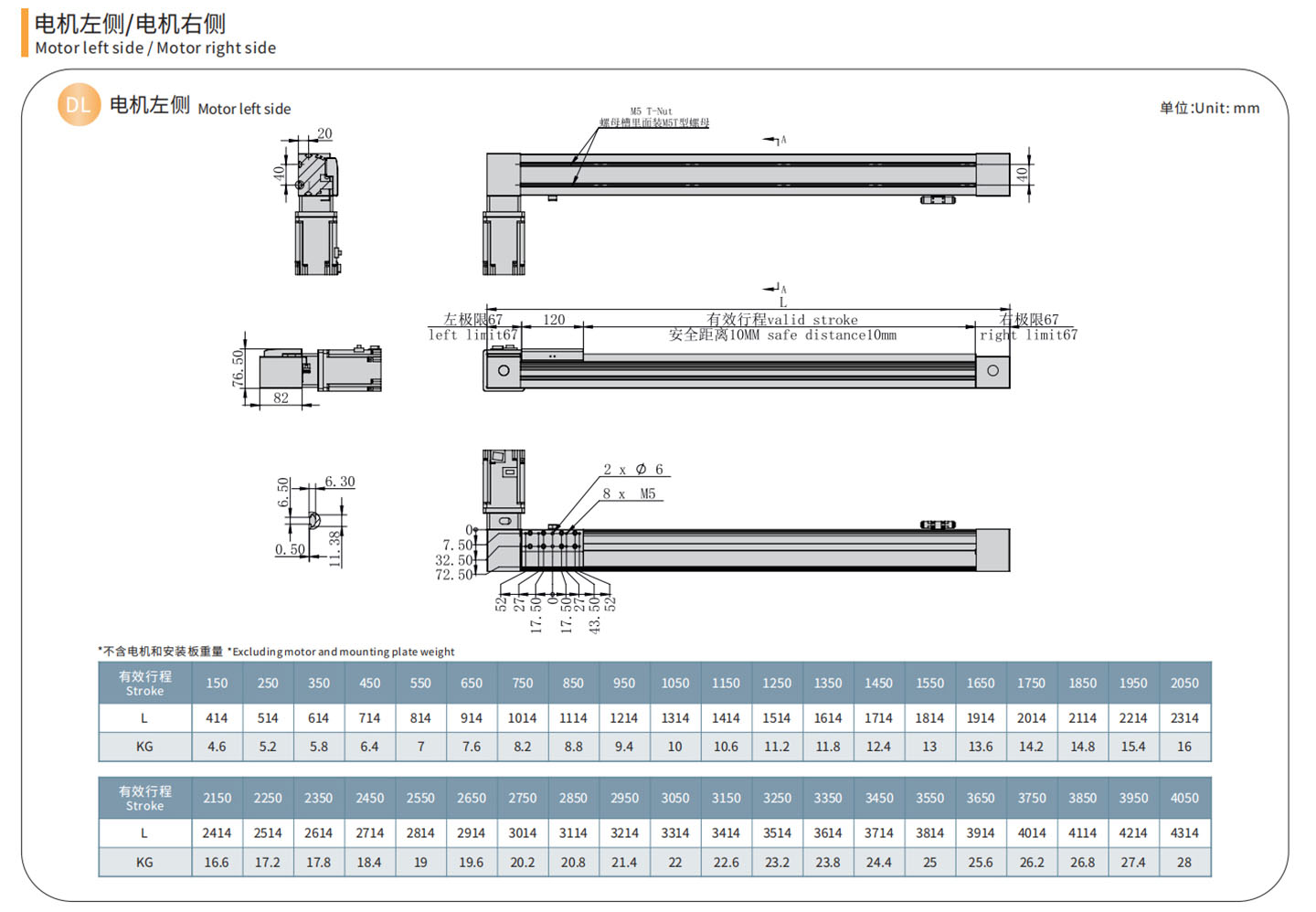

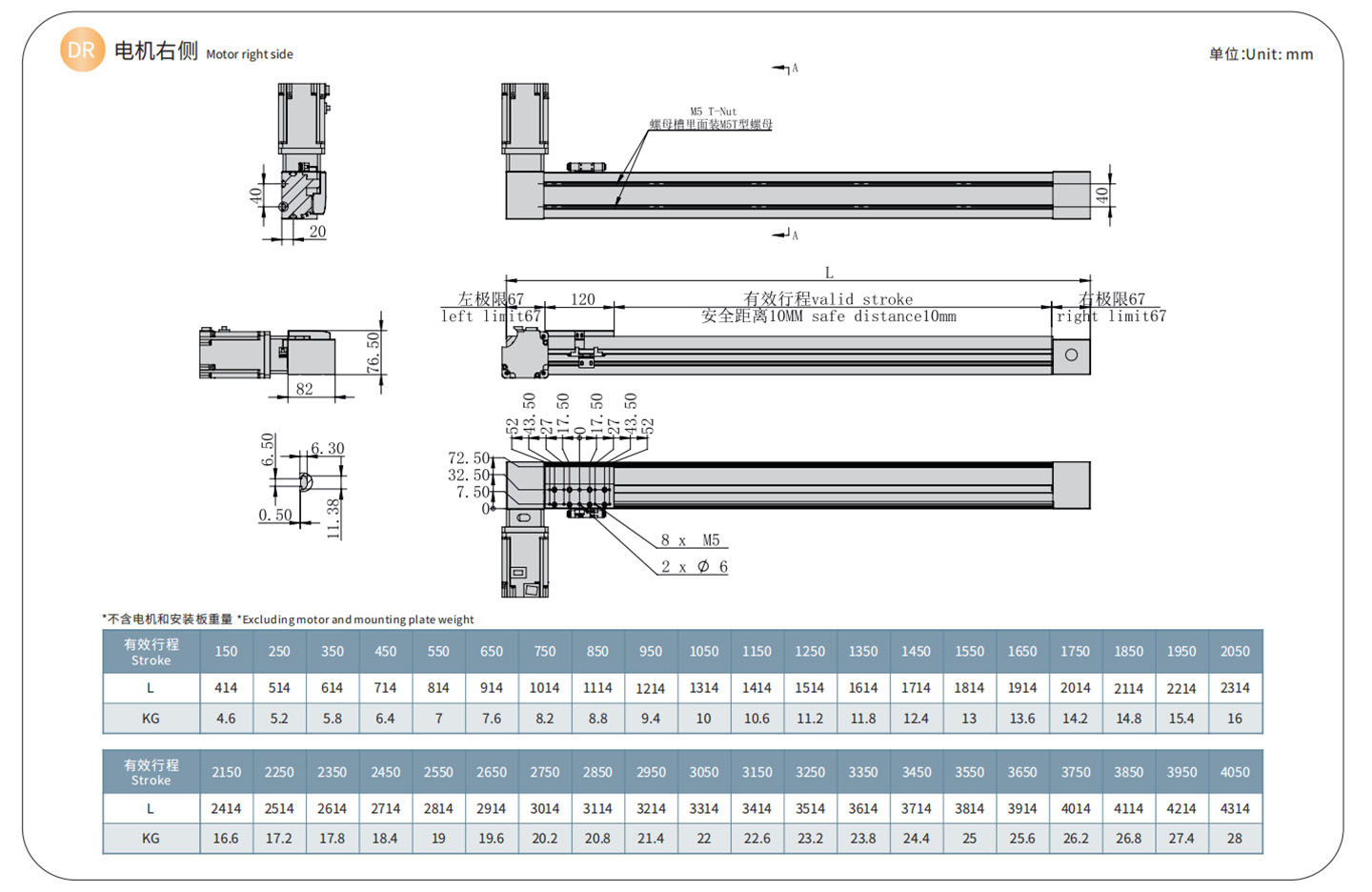

Easy installation, the three sides of the profile are designed with slider nut grooves, and any three sides can be installed.

More products