KSR/KNR/KCR/KFR Series Single Axis Robots Steel Base

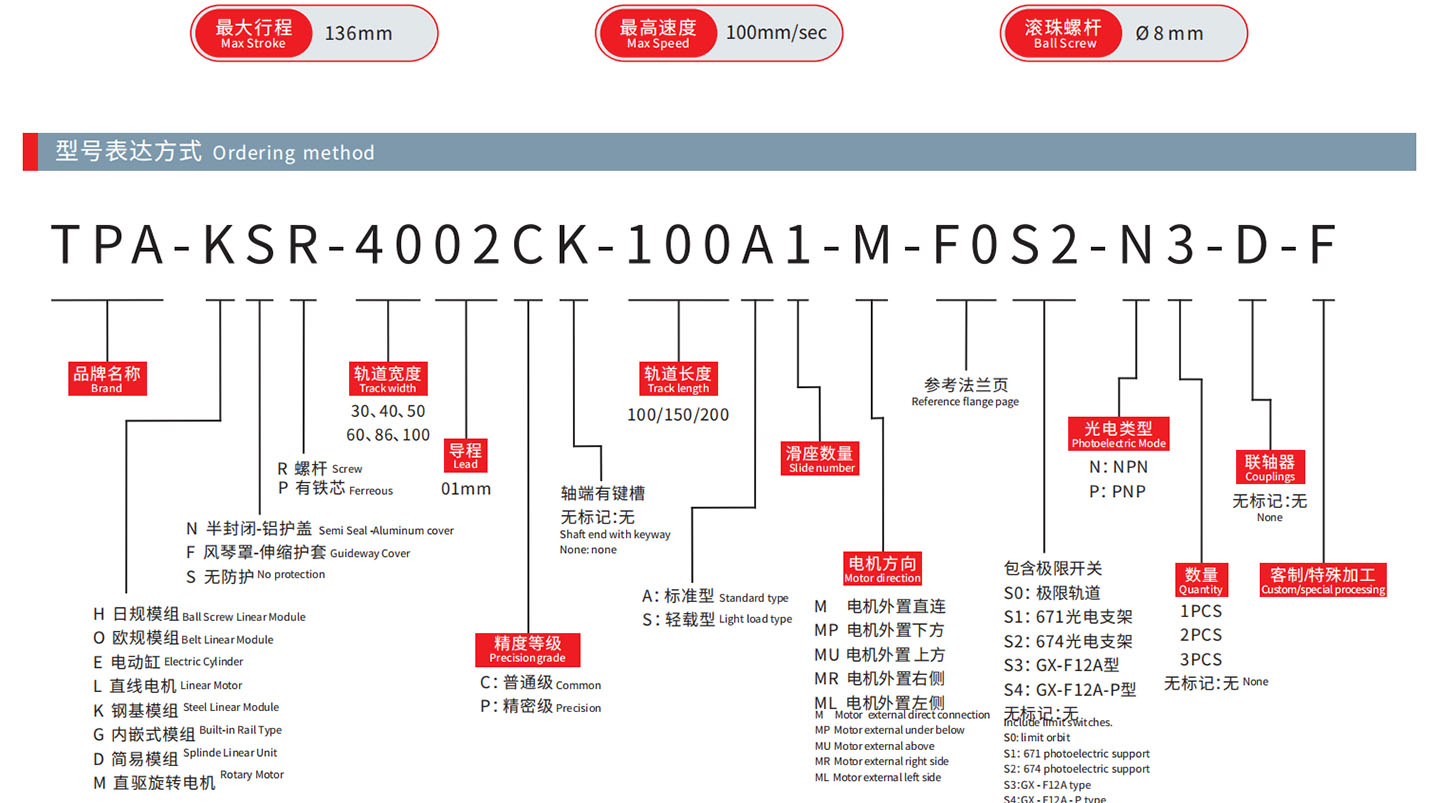

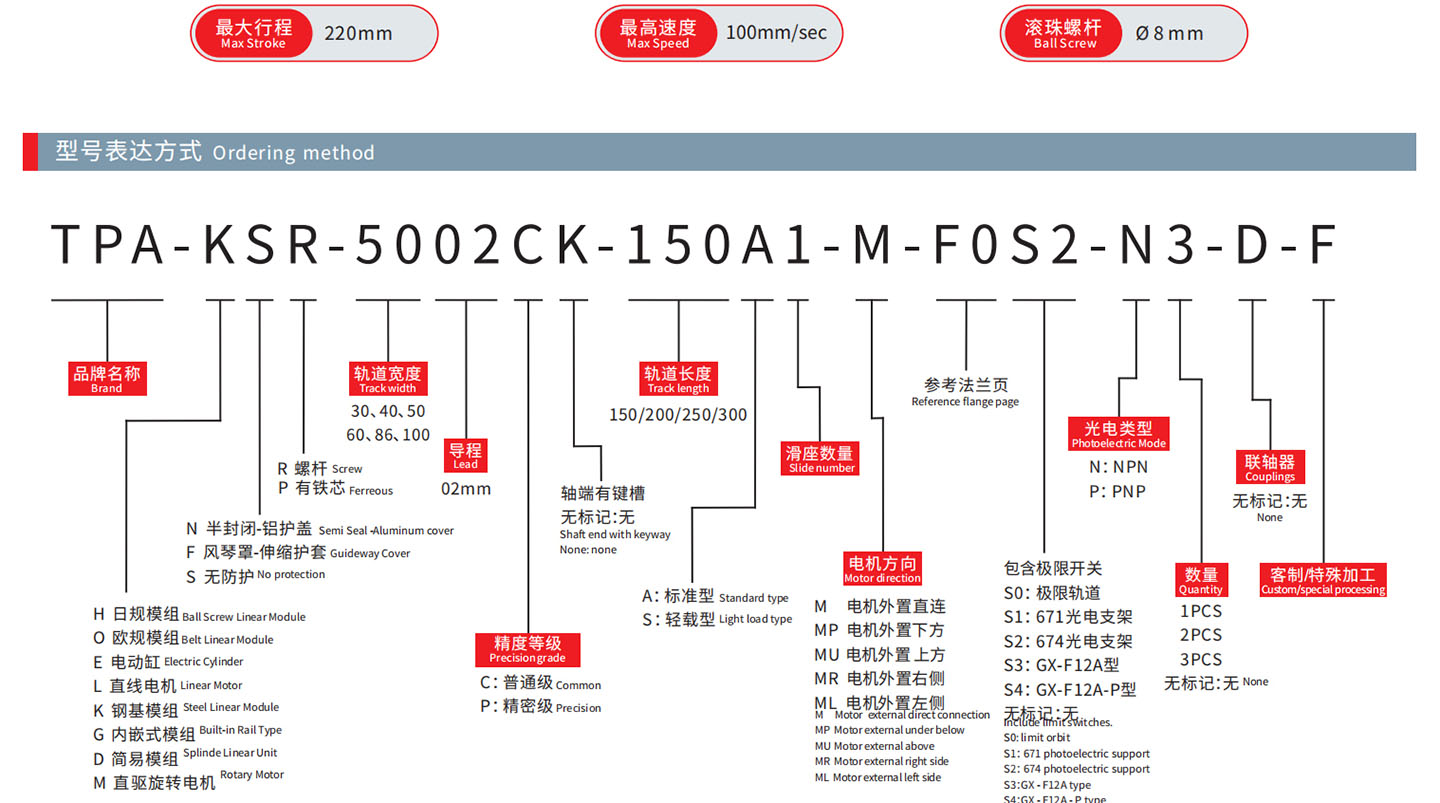

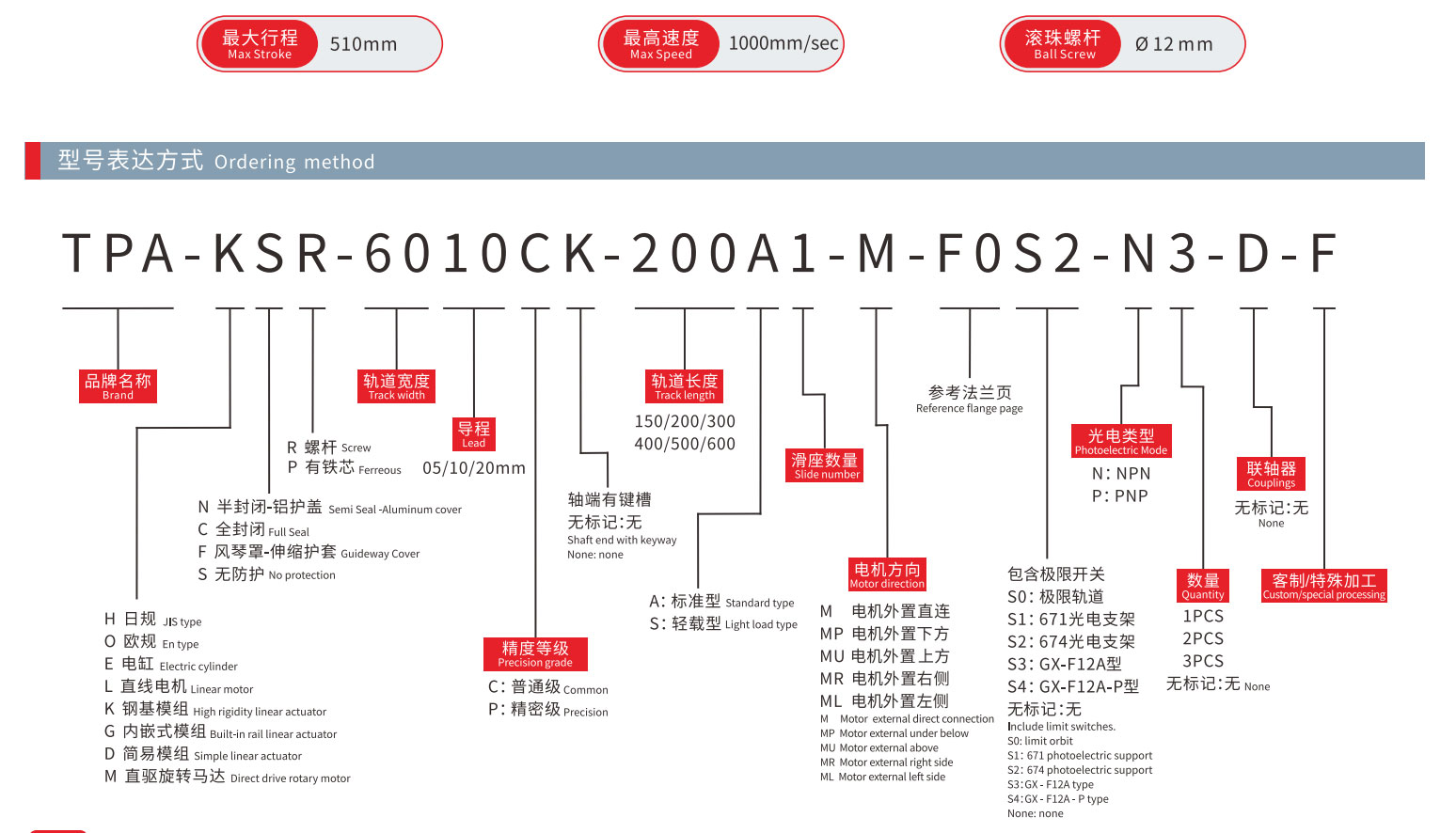

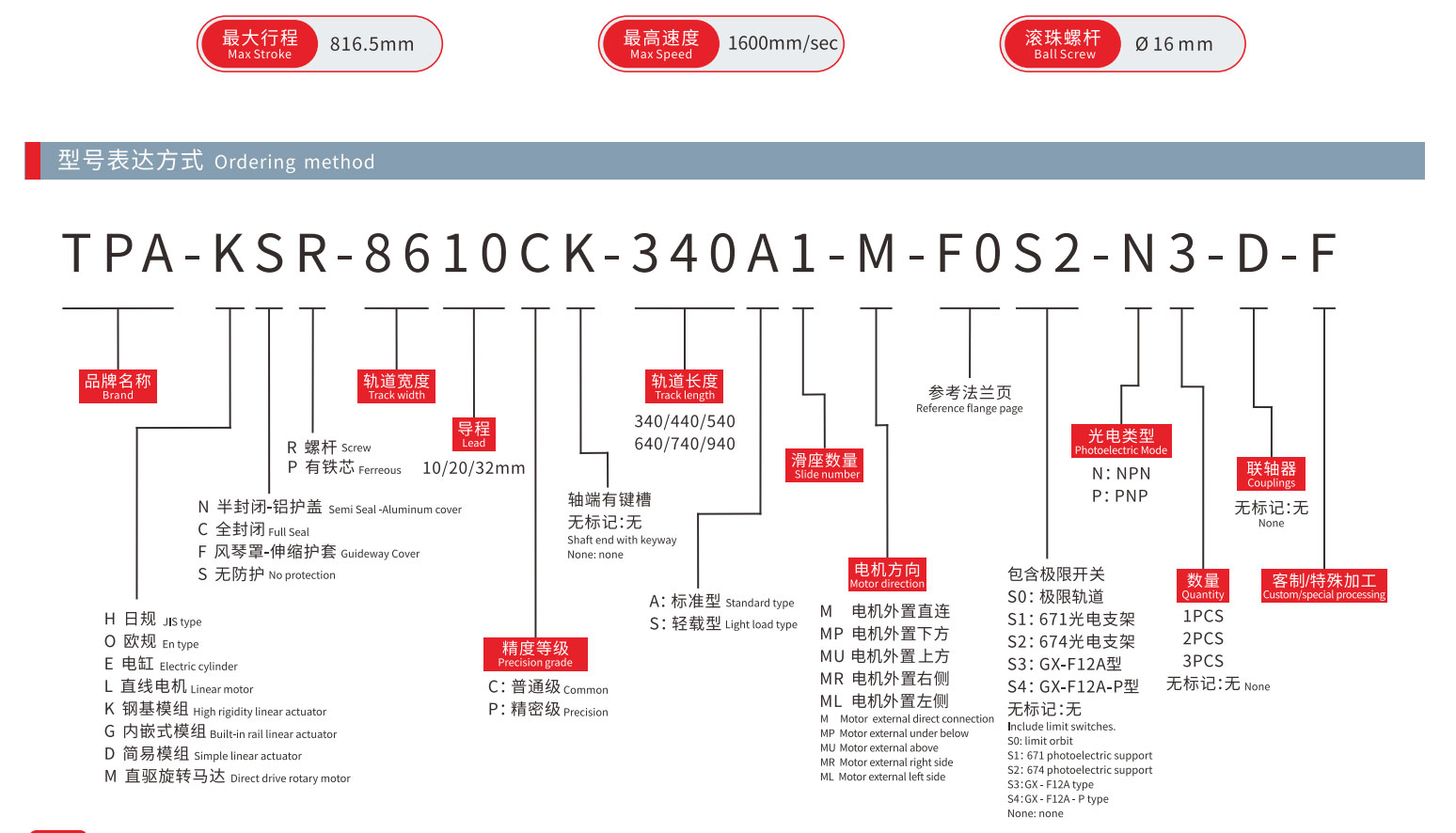

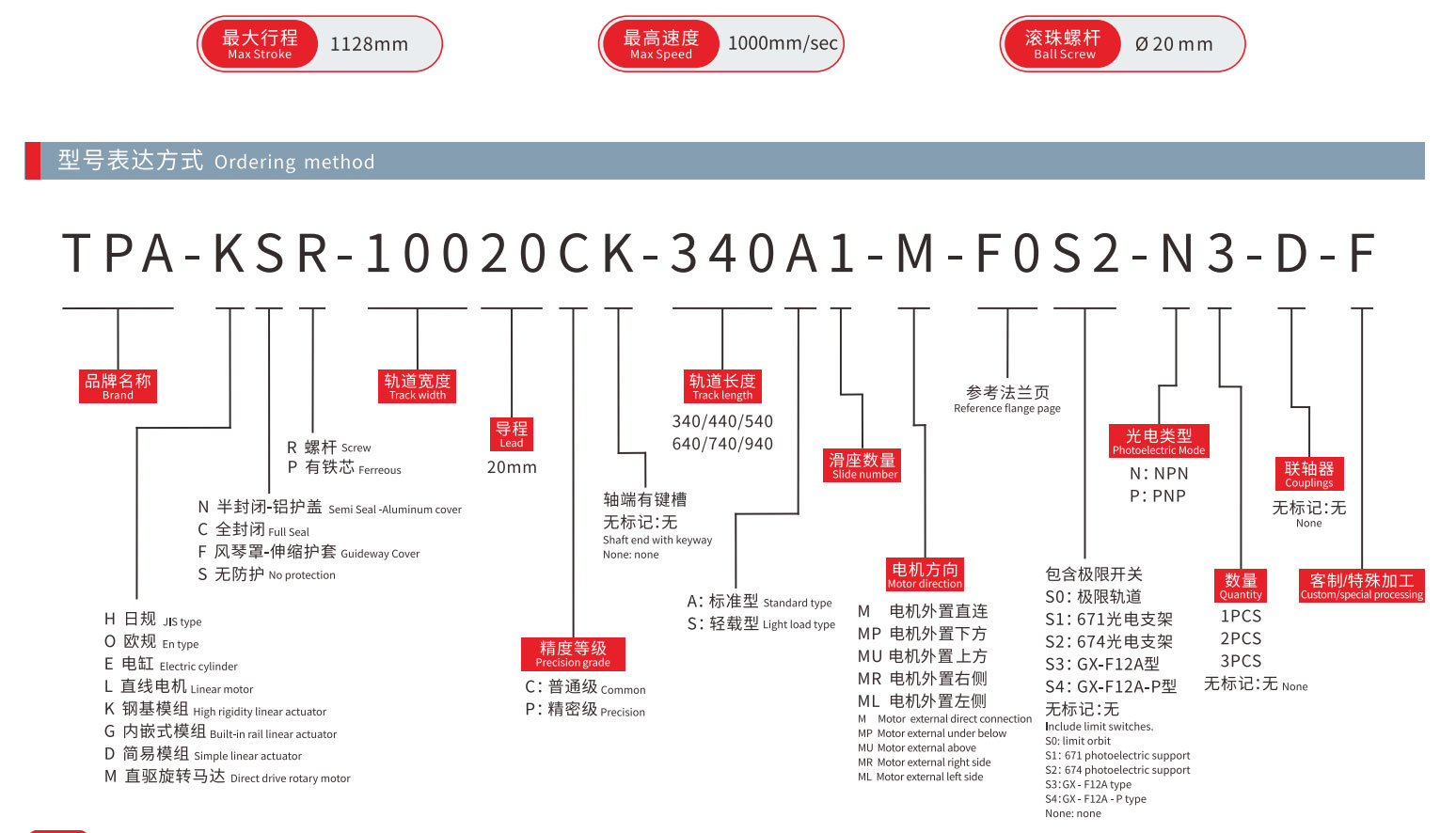

Model Selector

TPA-?-???-?-???-?-??-?-?

TPA-?-???-?-???-?-??-?-?

TPA-?-???-?-???-?-??-?-?

TPA-?-???-?-???-?-??-?-?

TPA-?-???-?-???-?-??-?-?

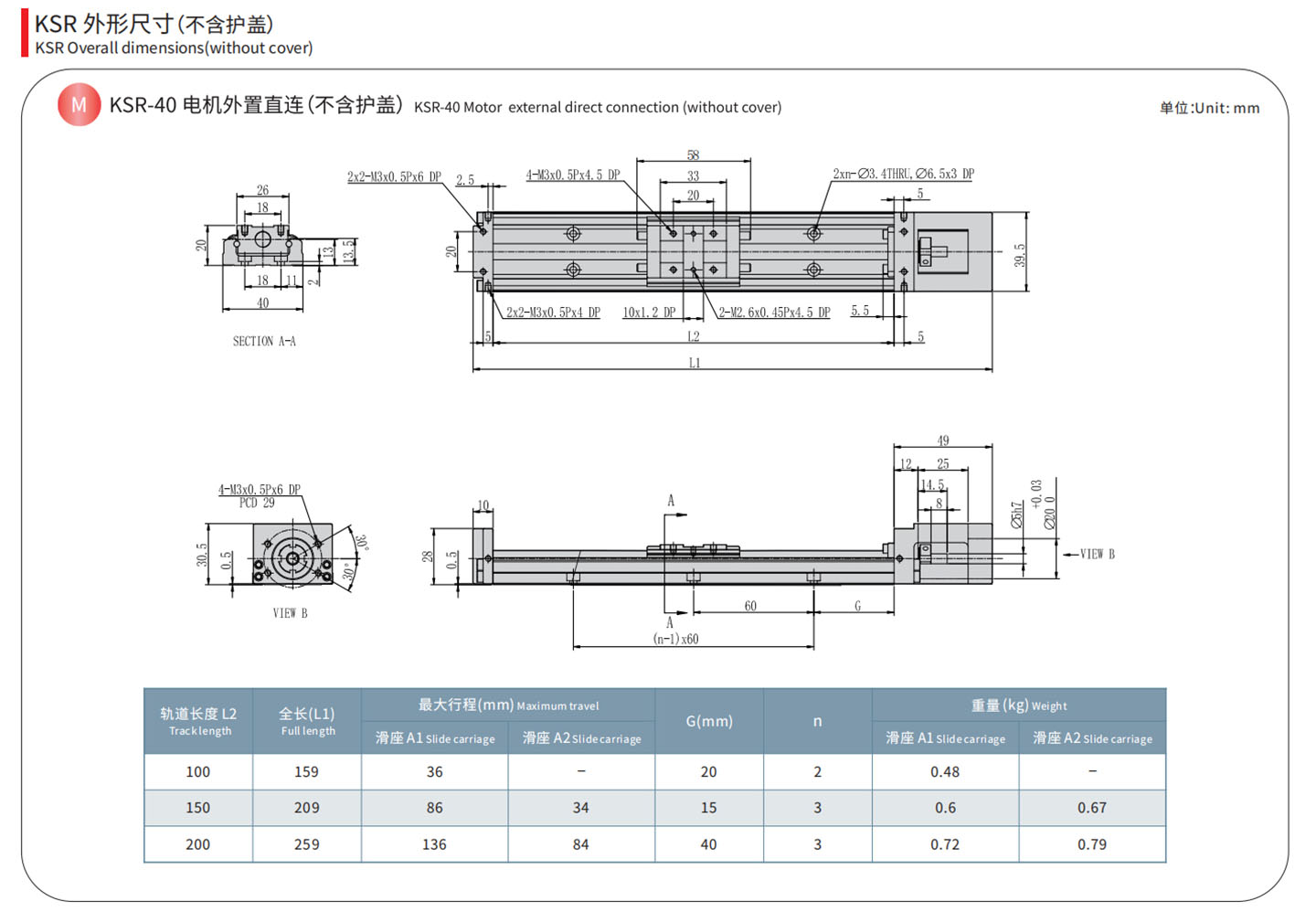

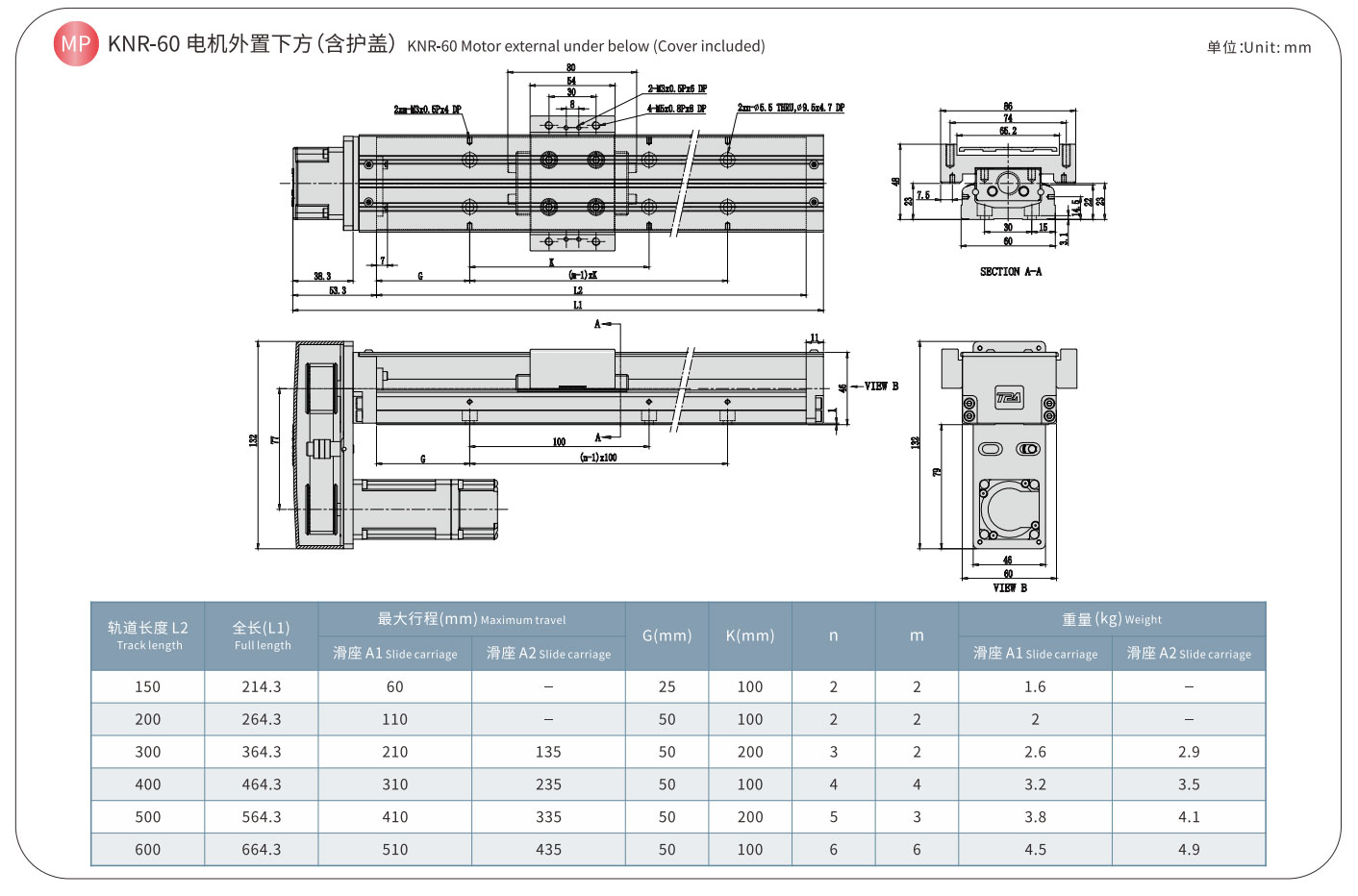

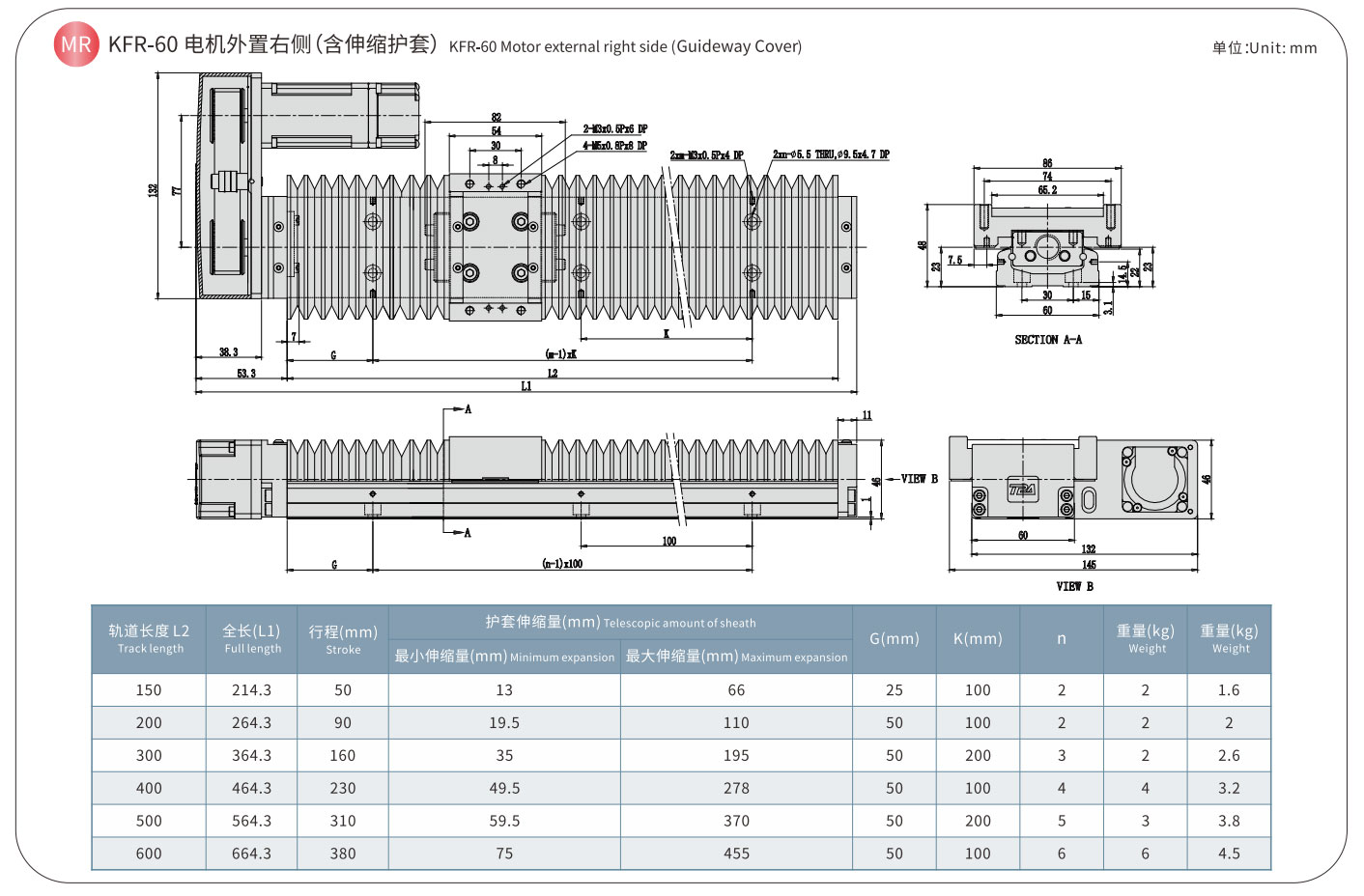

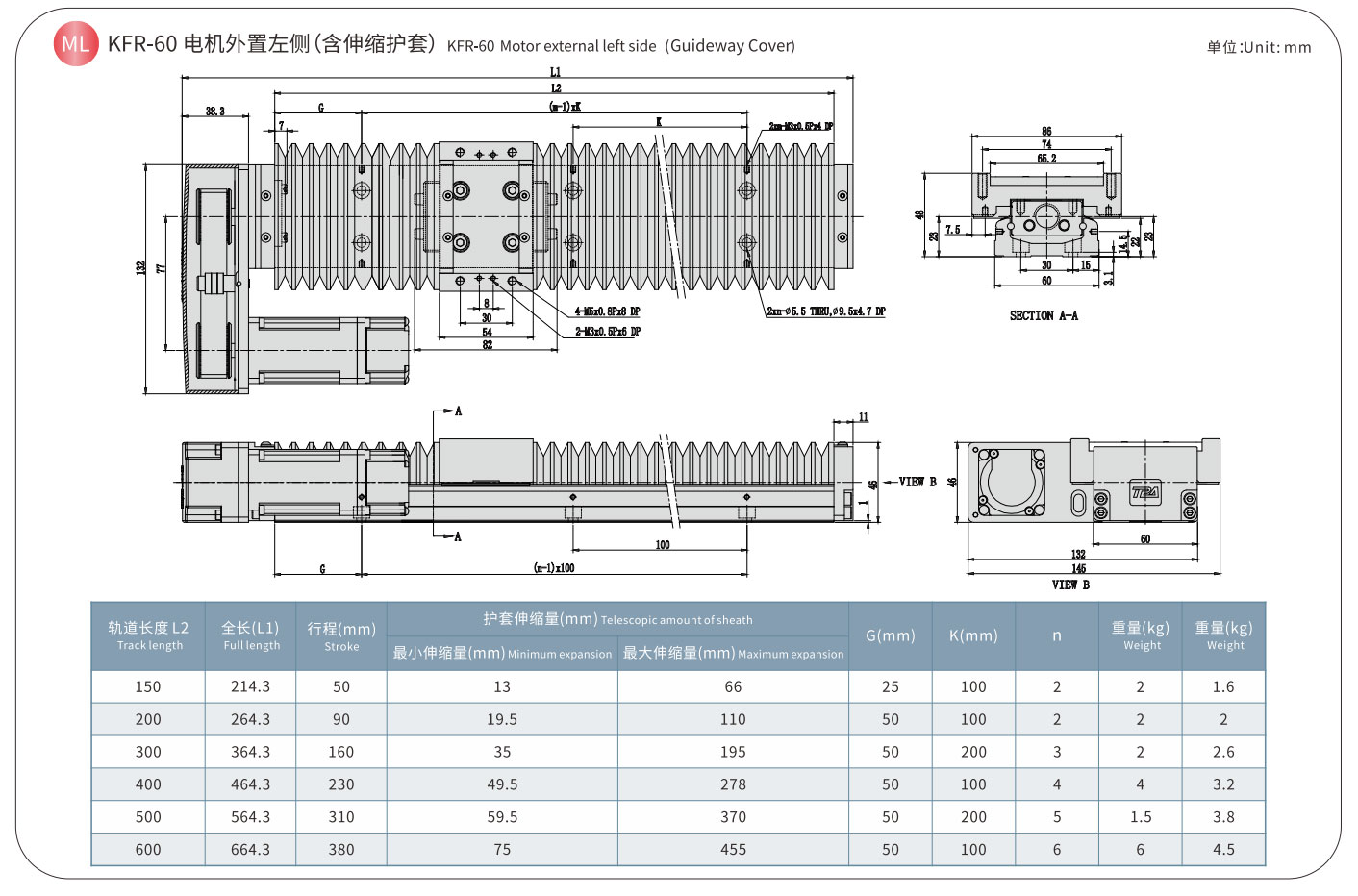

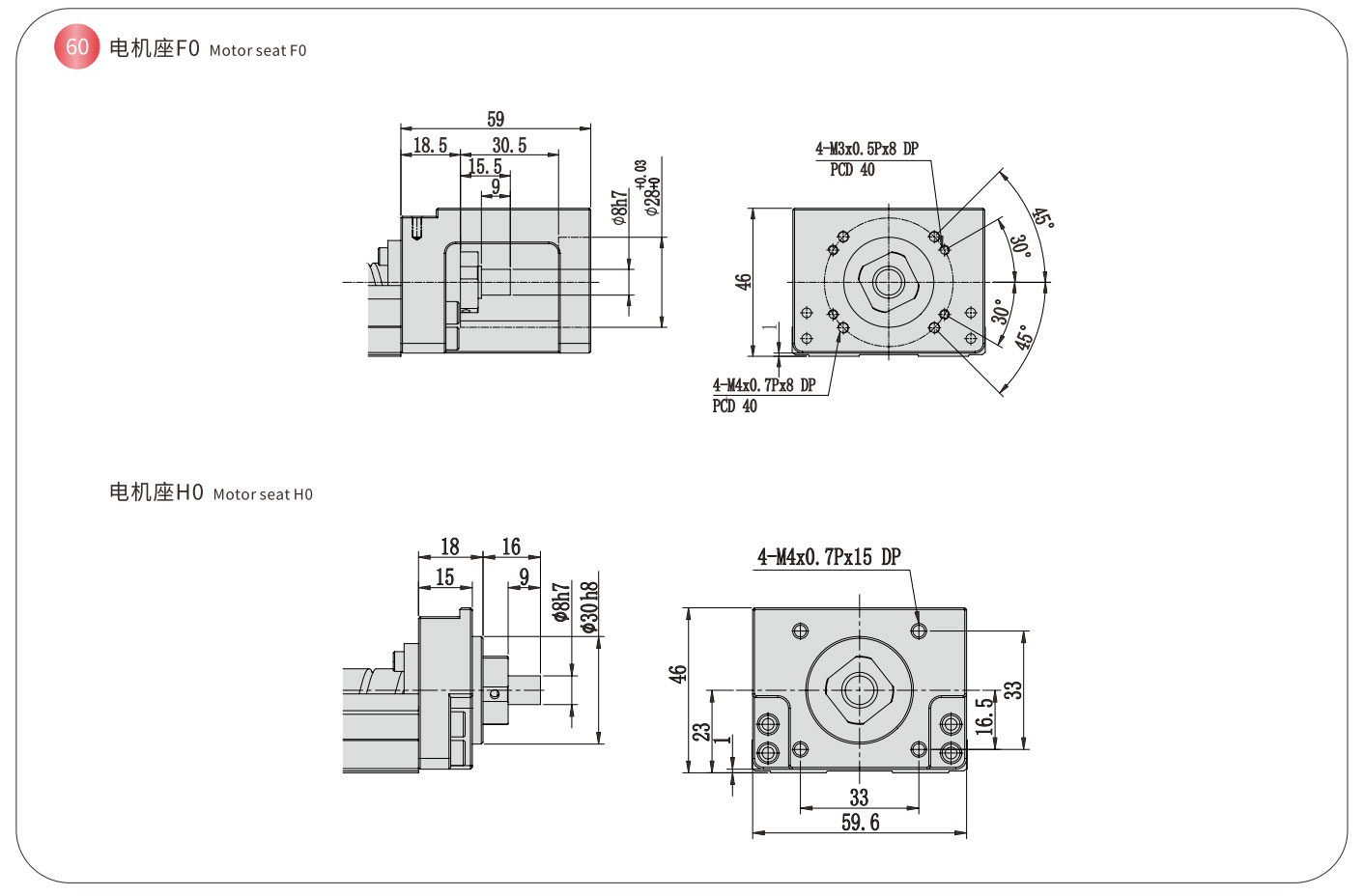

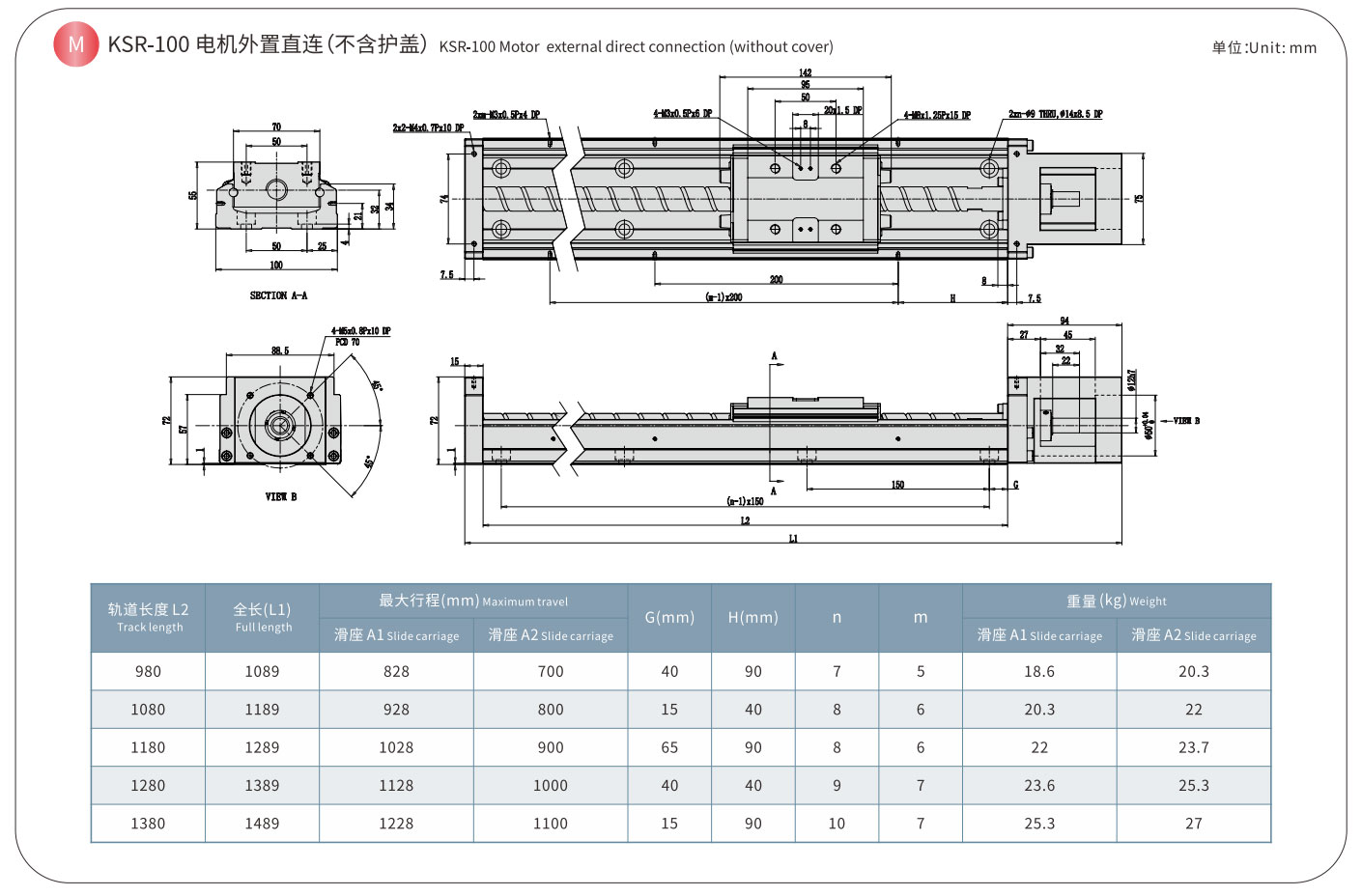

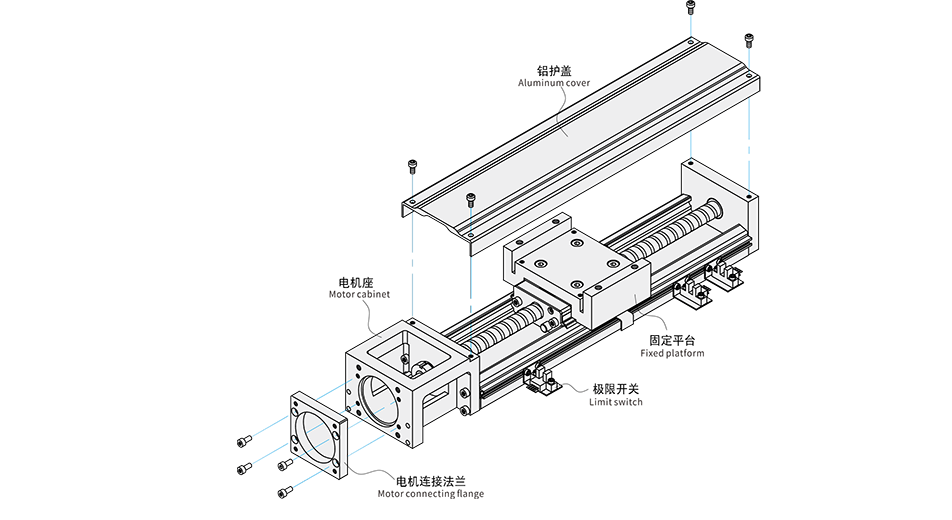

Product Detail

KK40

KK50

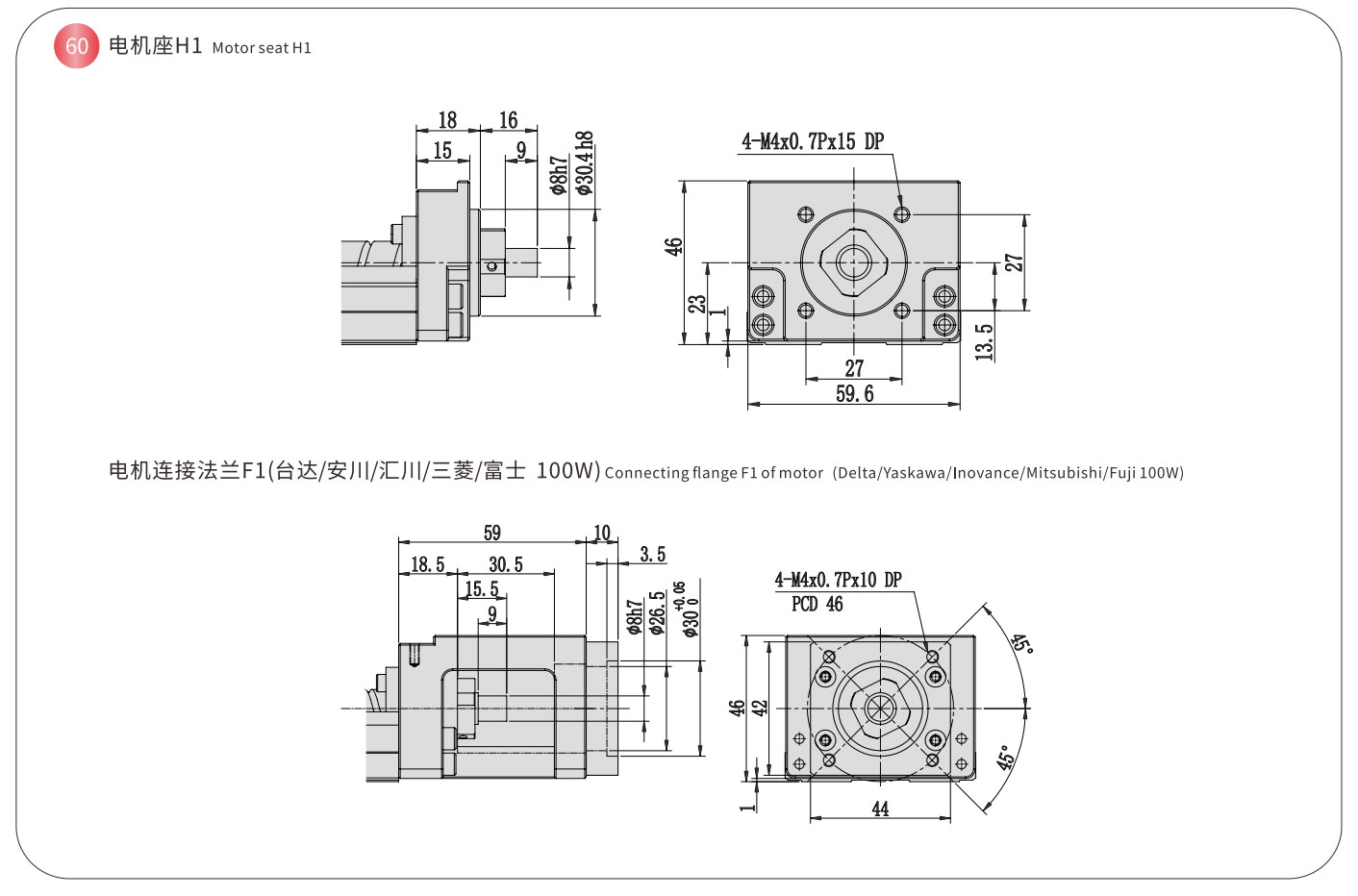

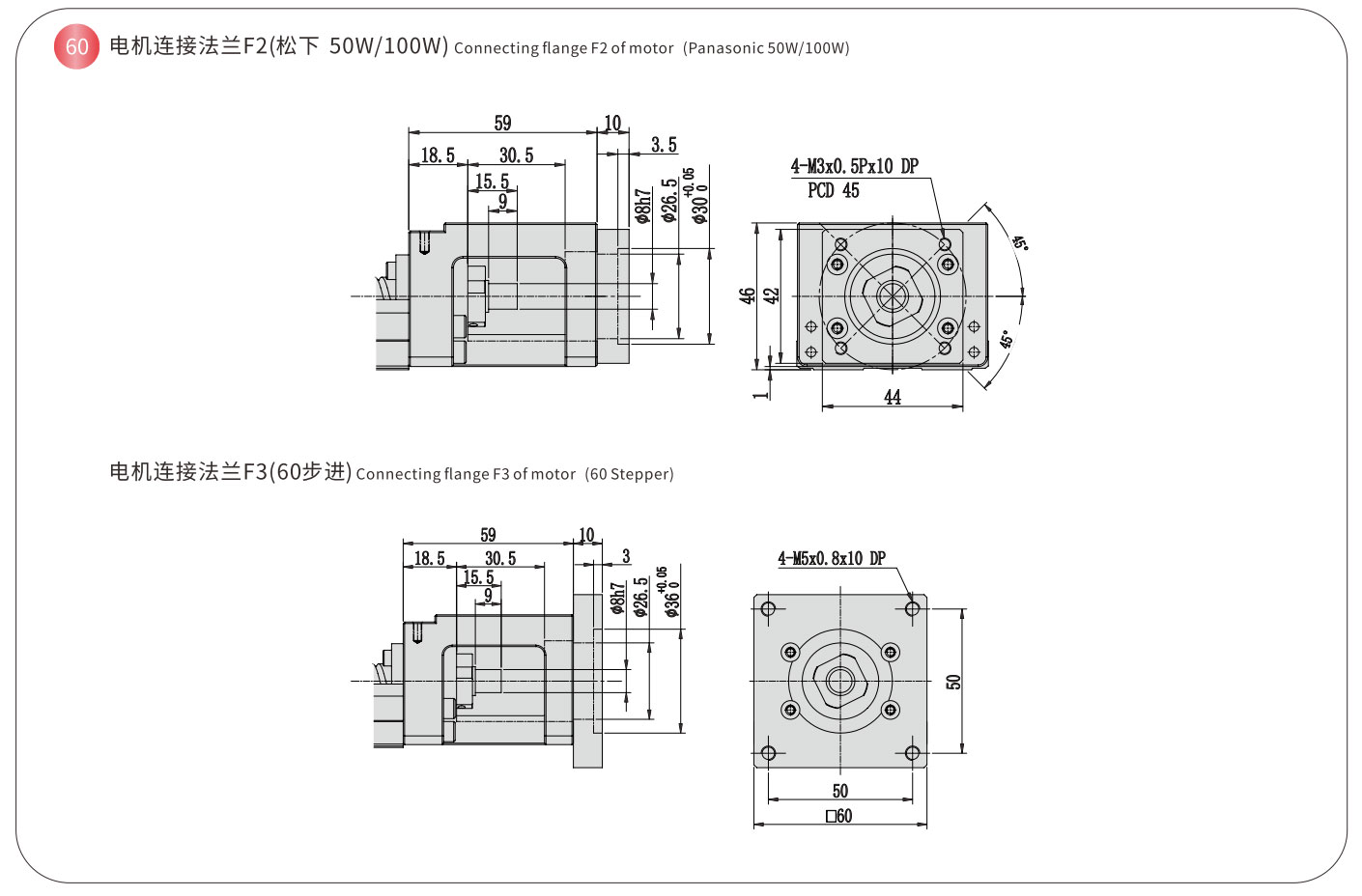

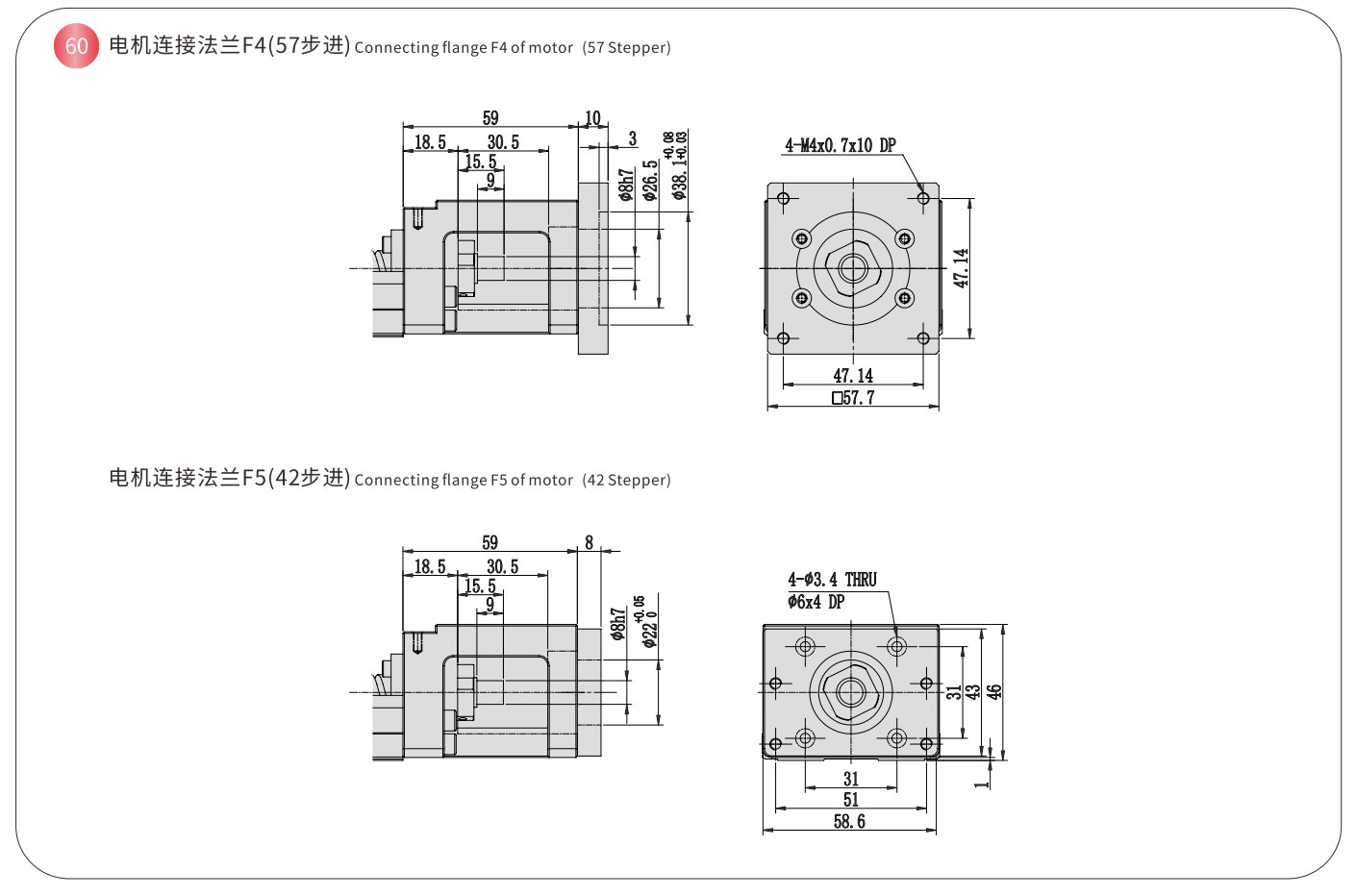

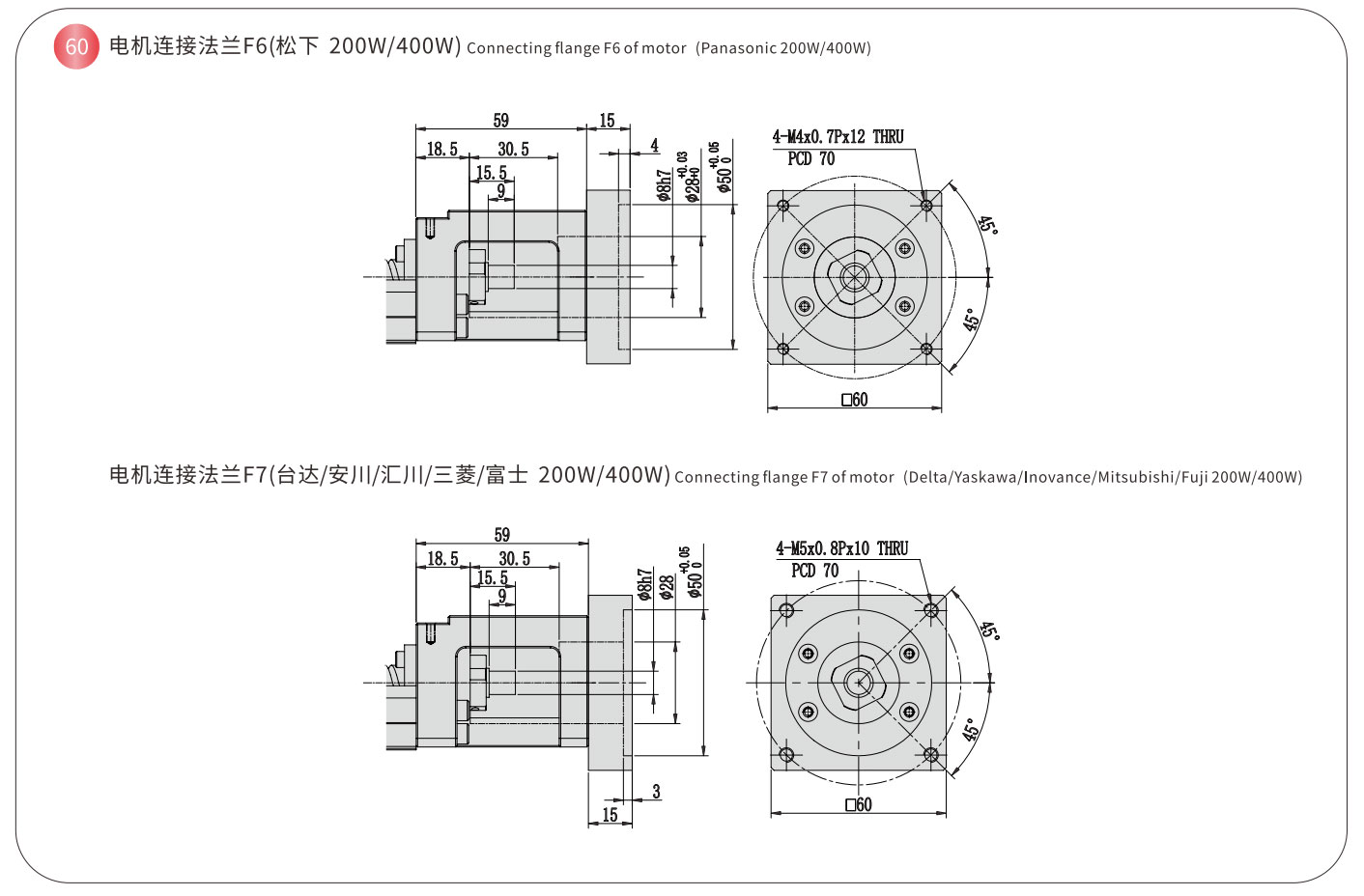

KK60

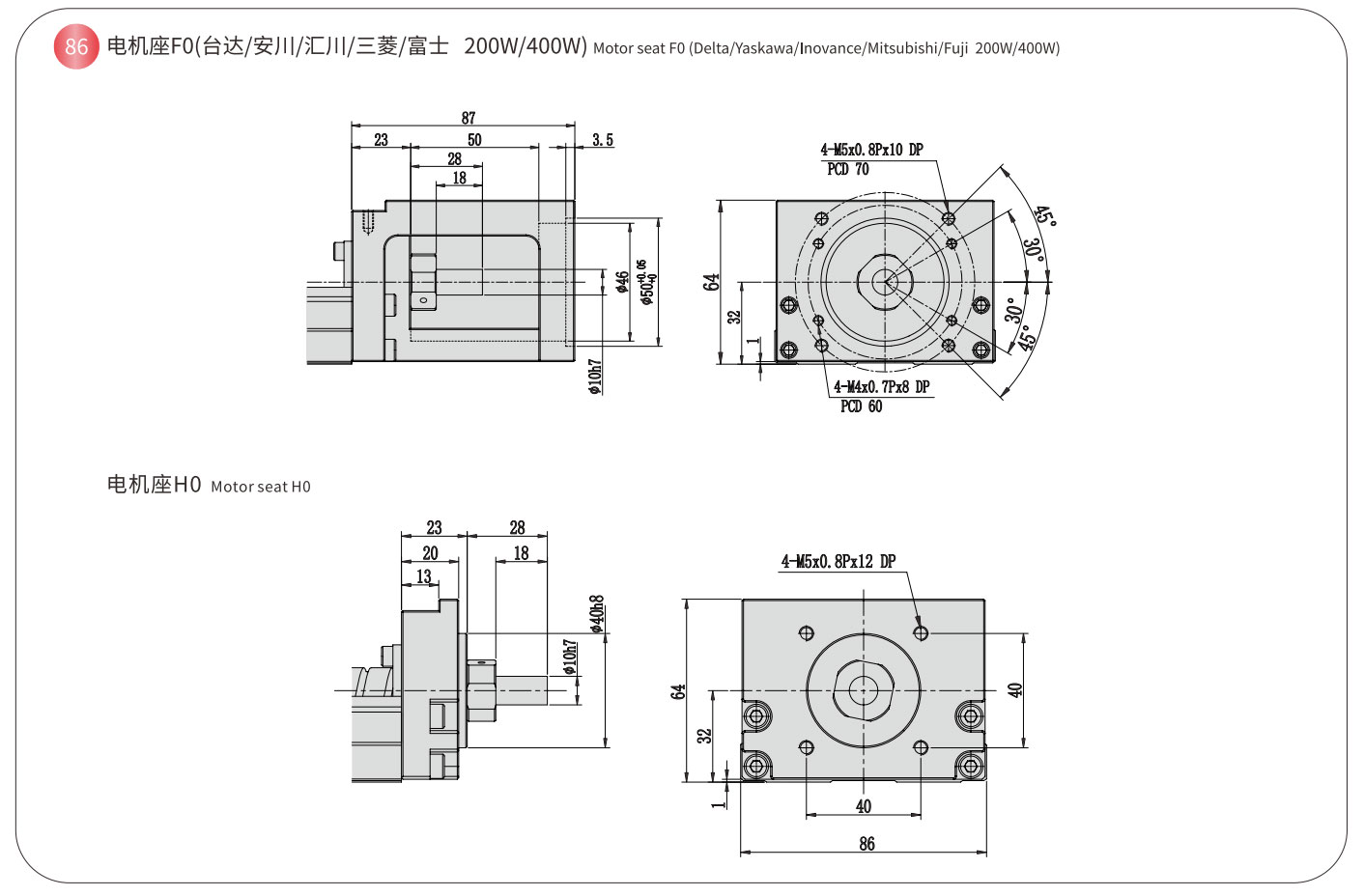

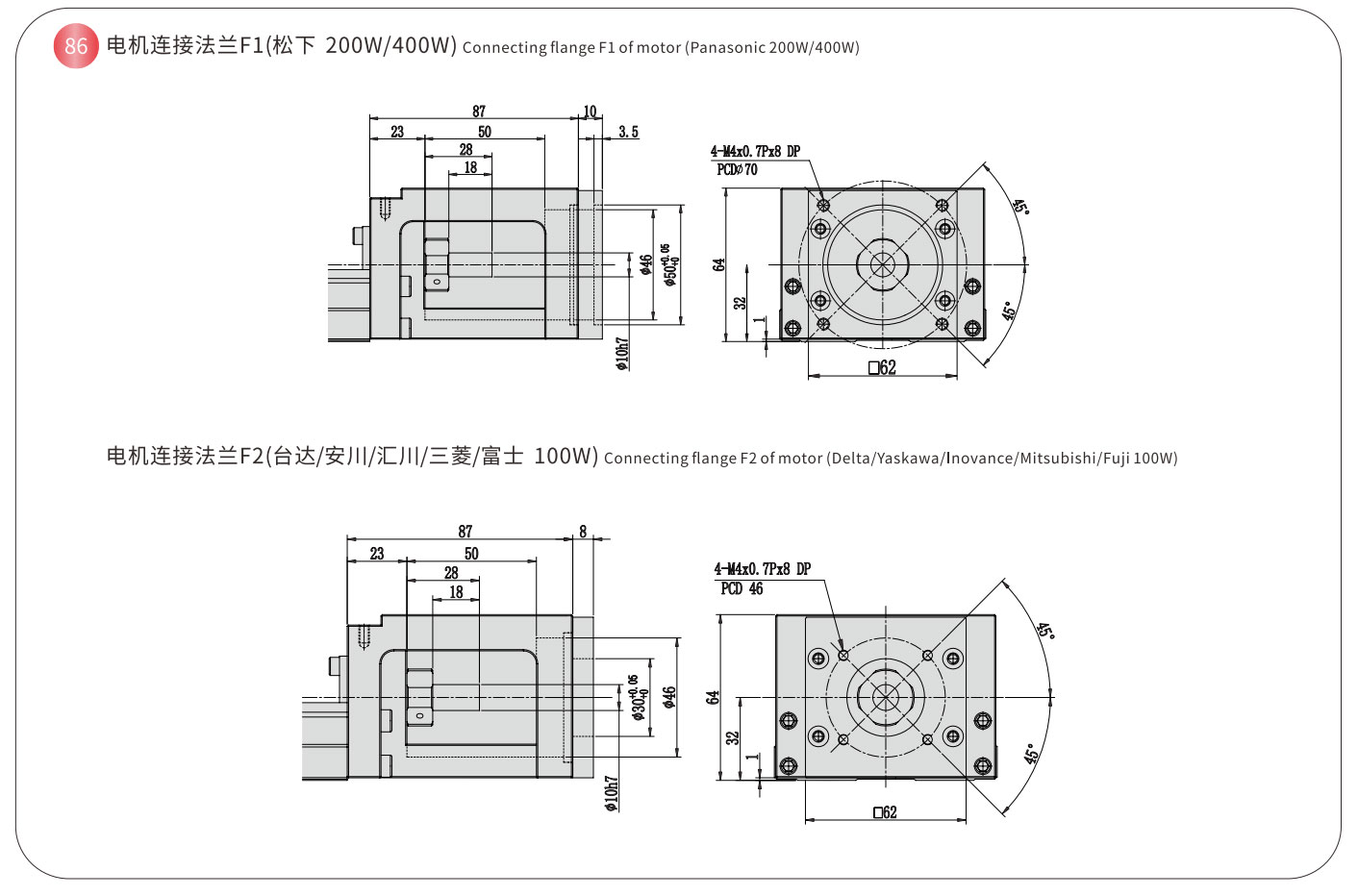

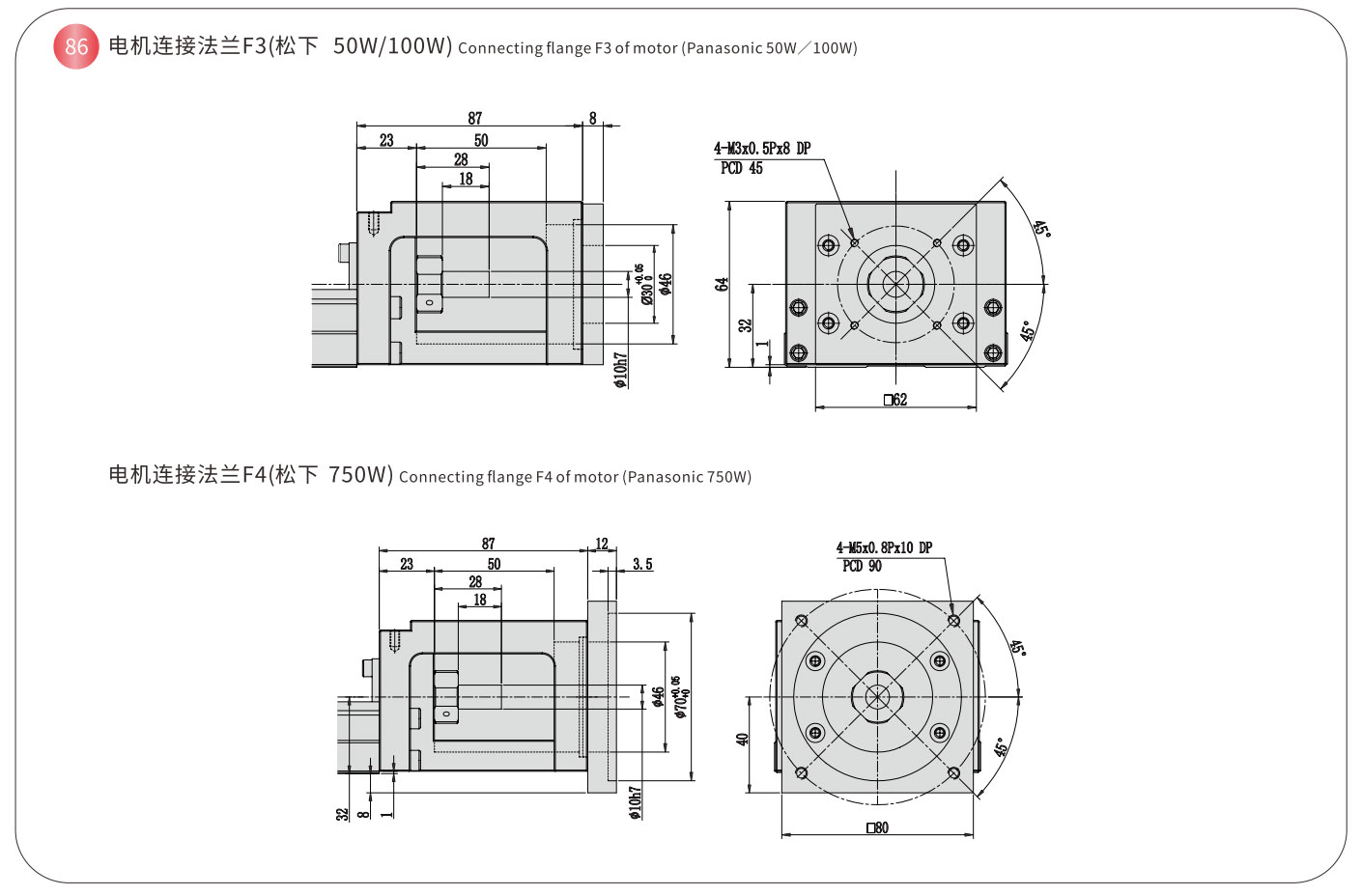

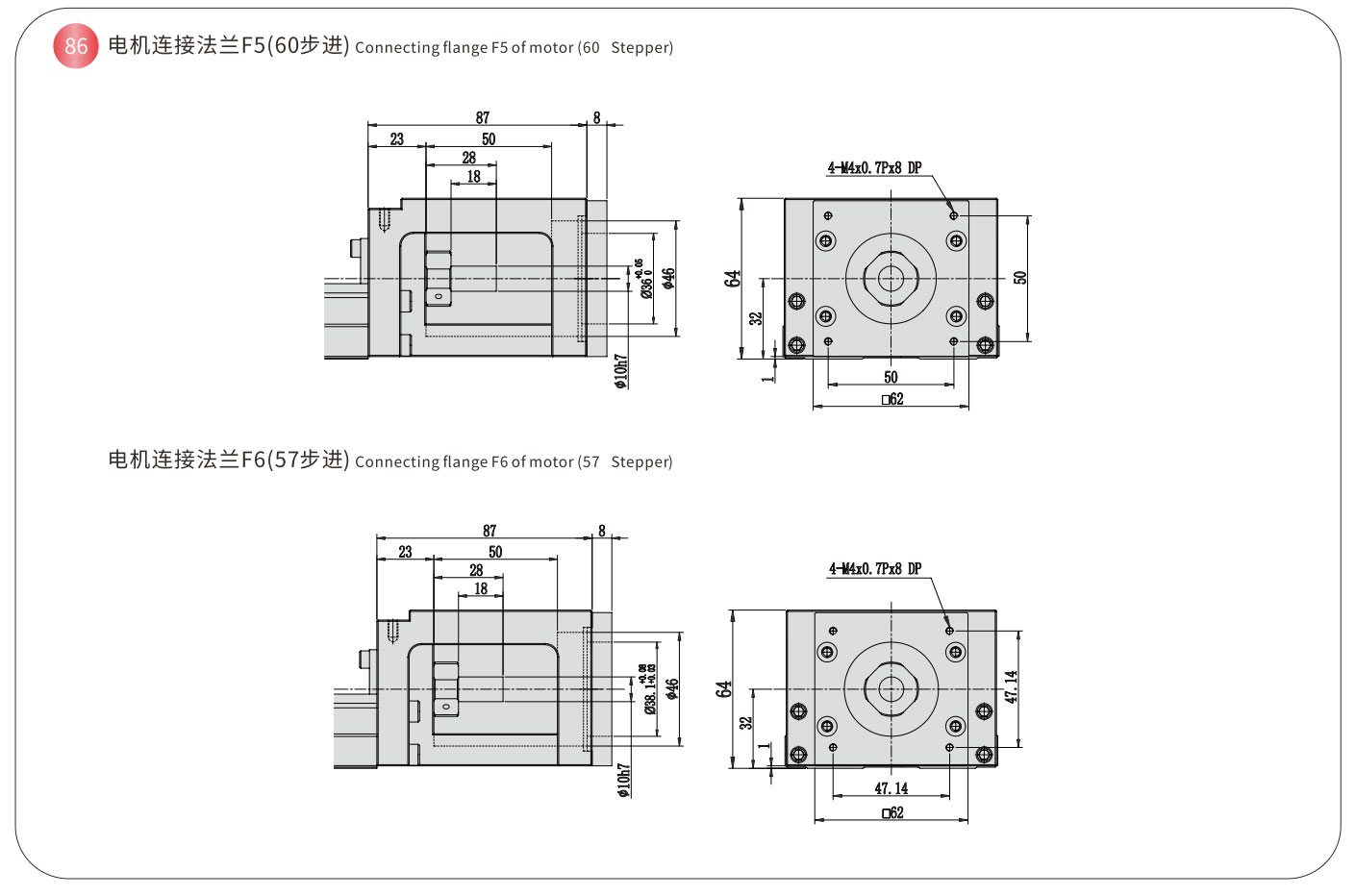

KK86

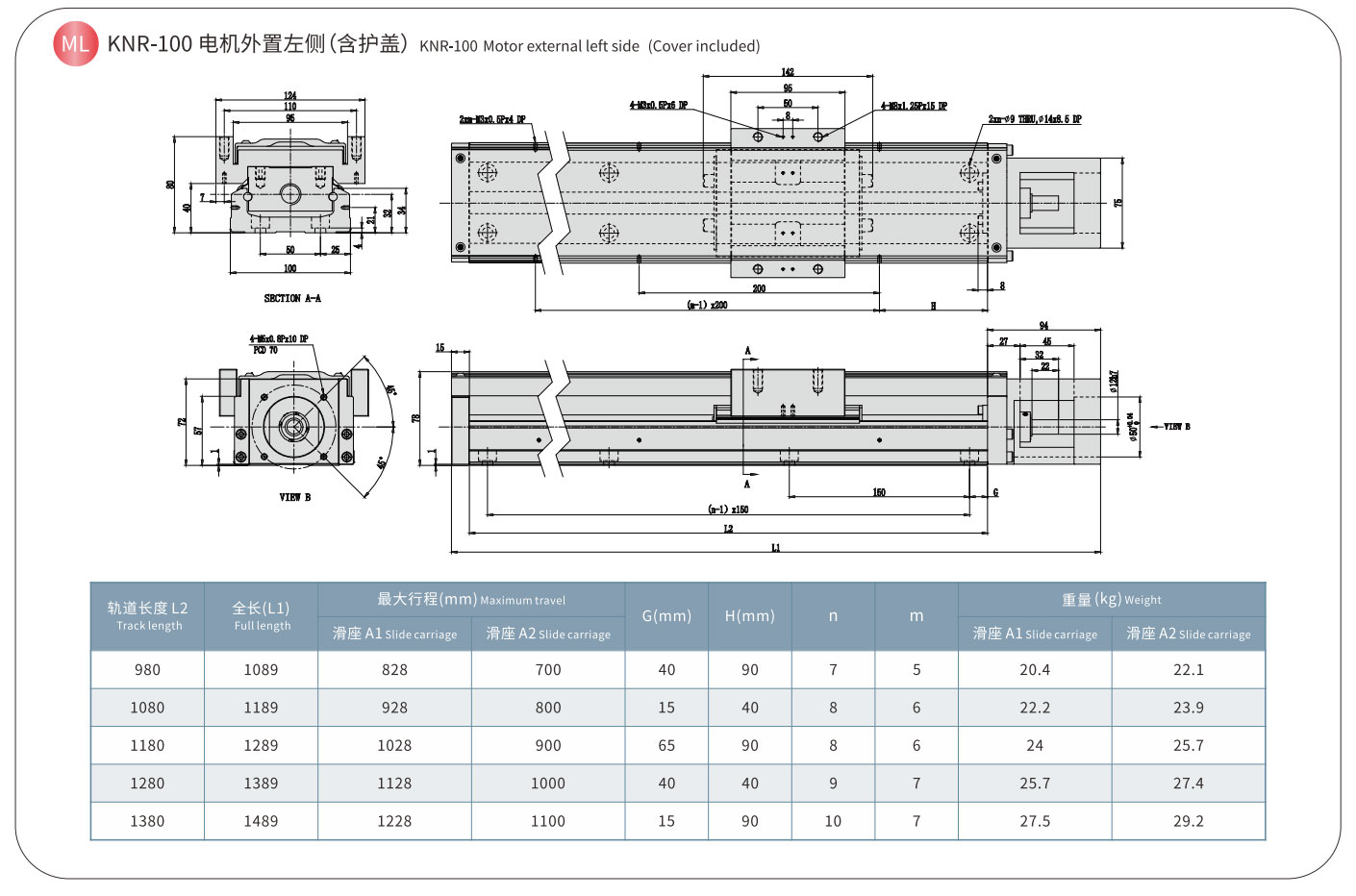

KK100

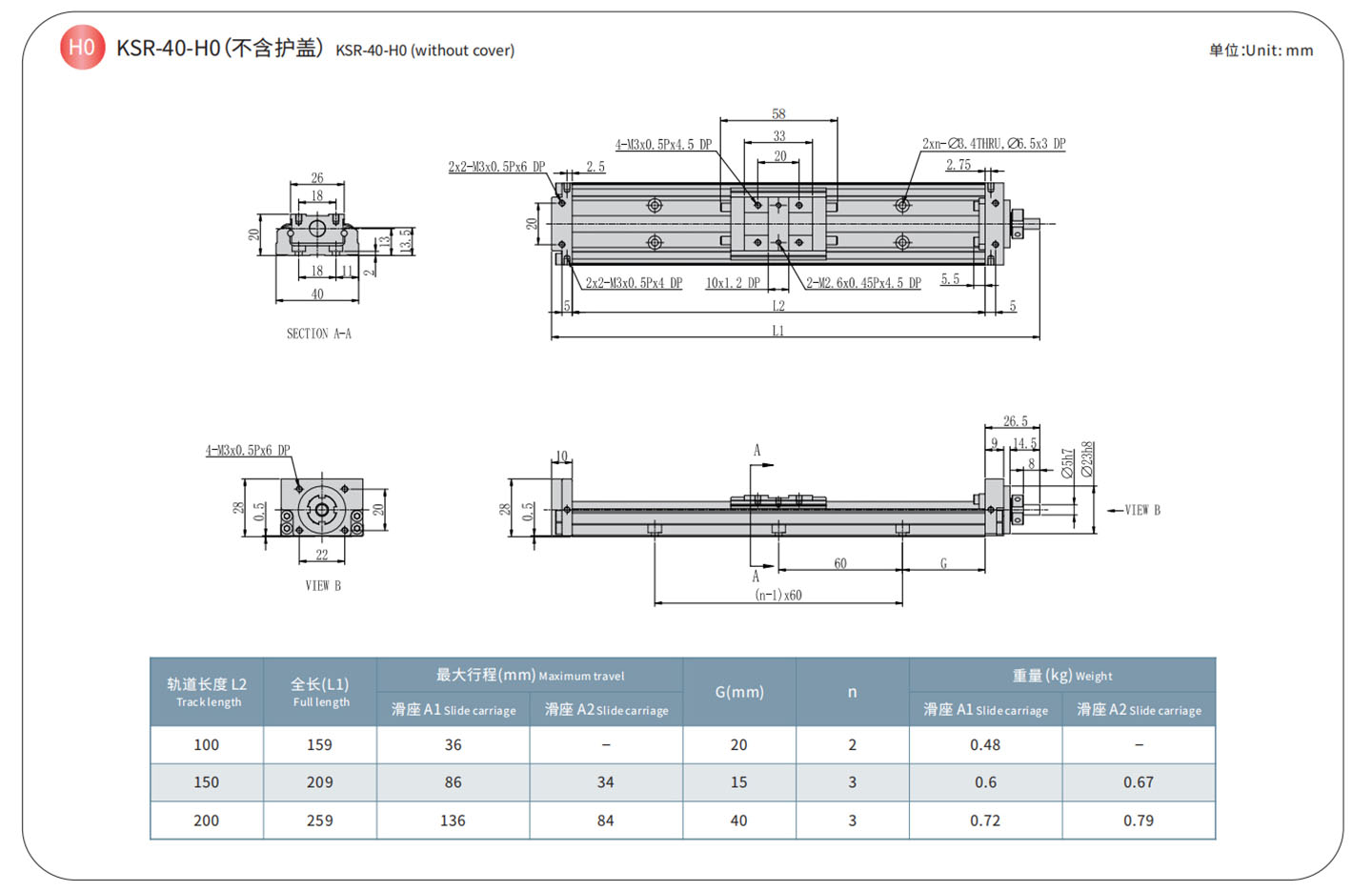

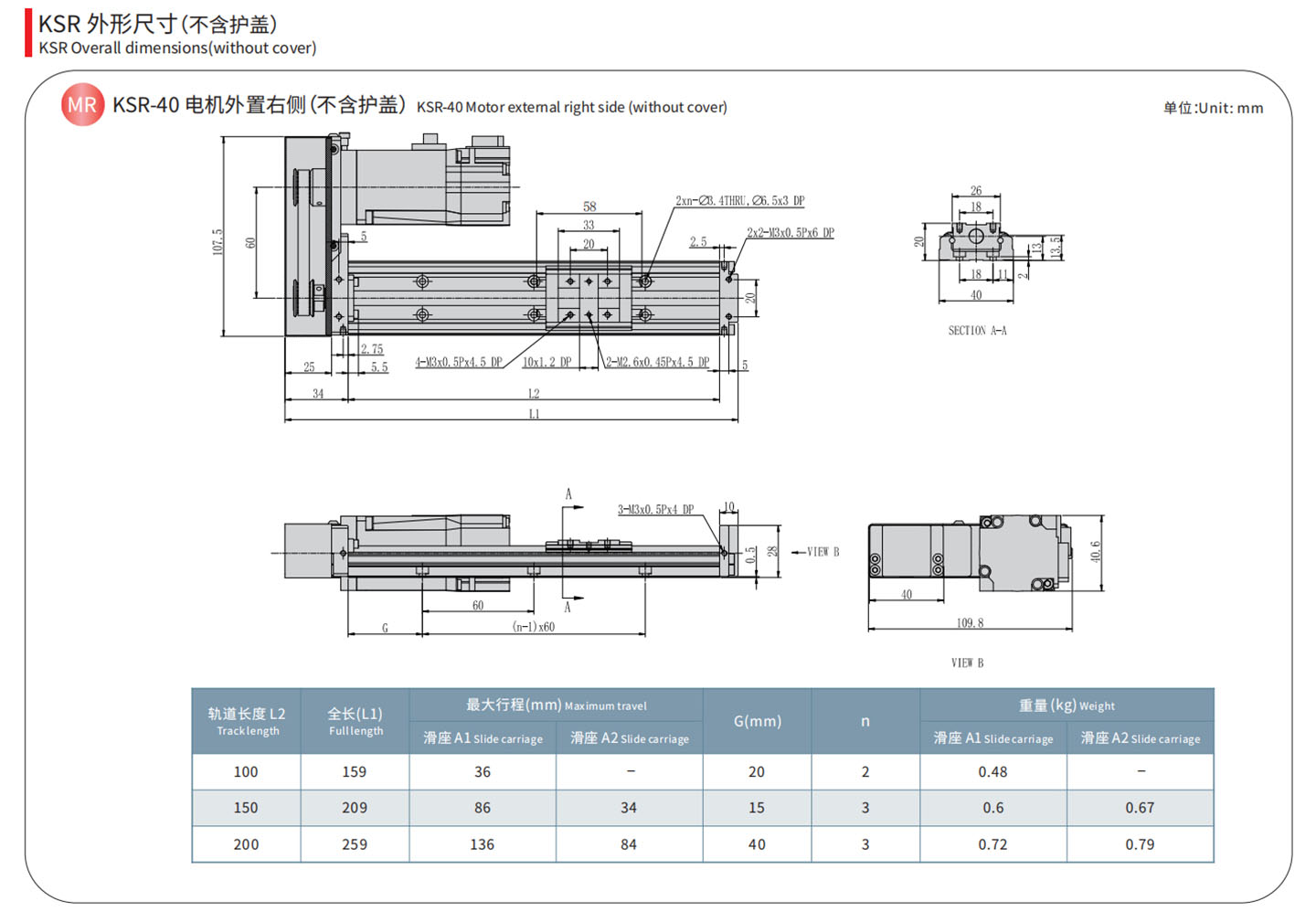

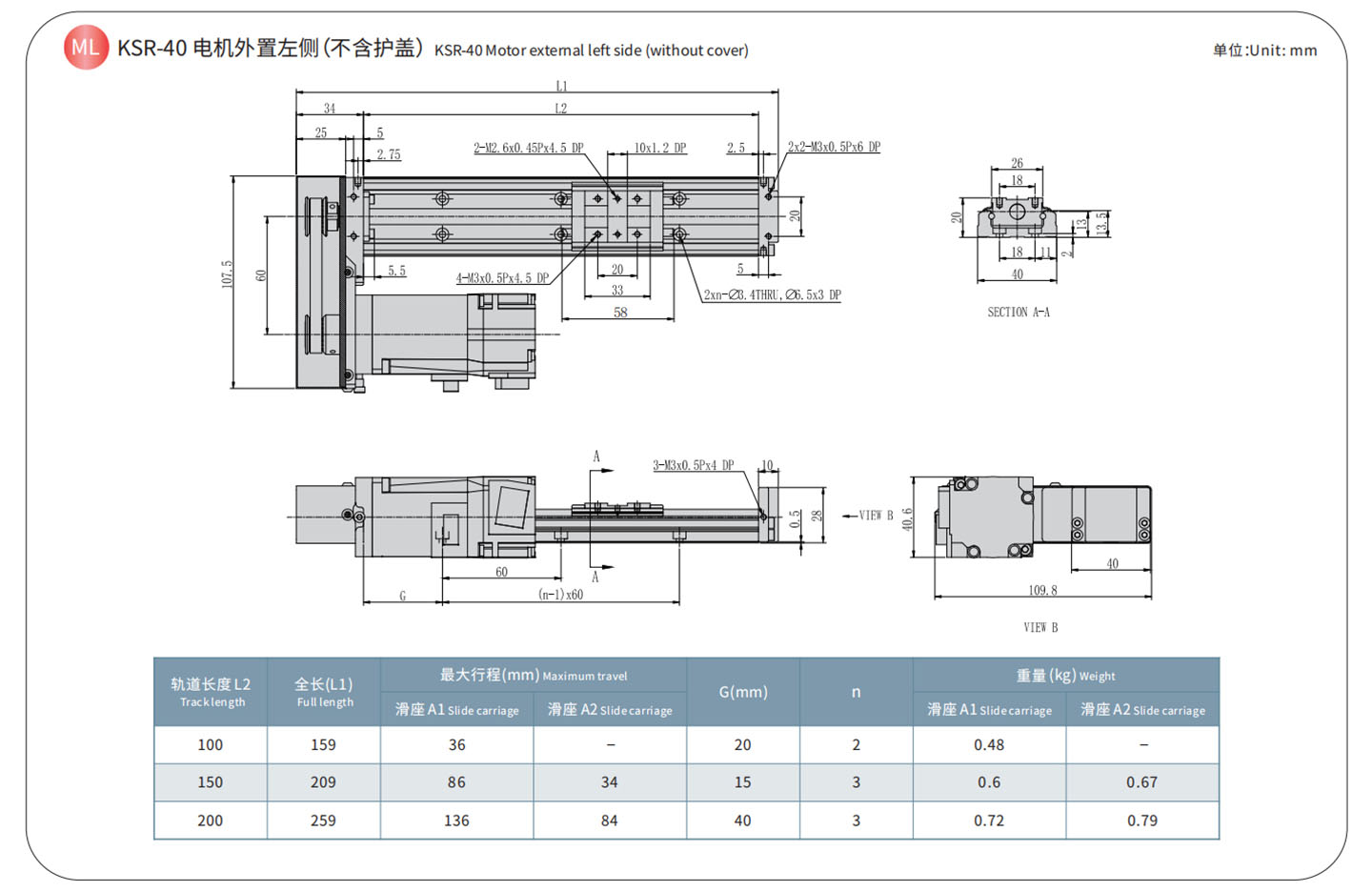

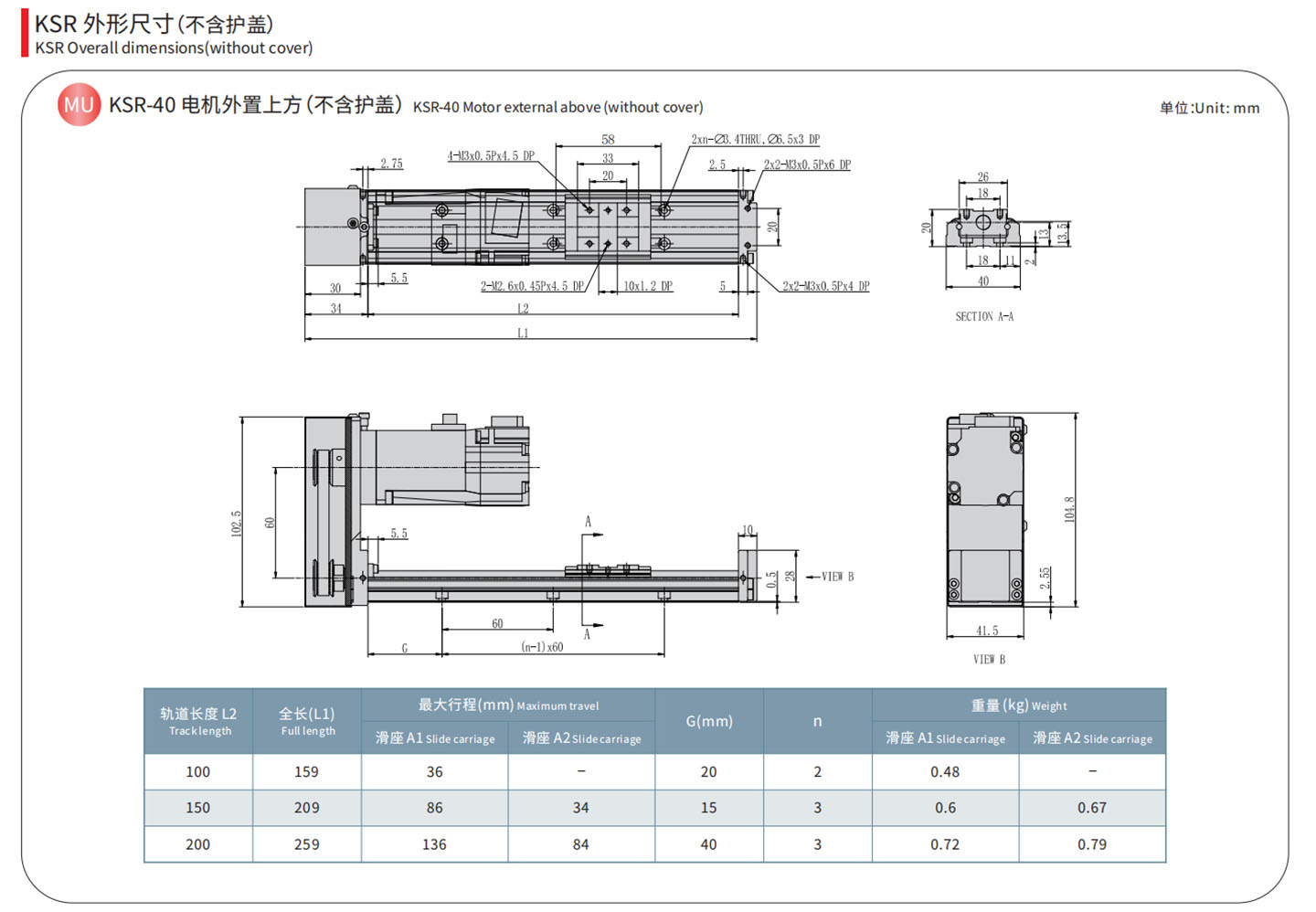

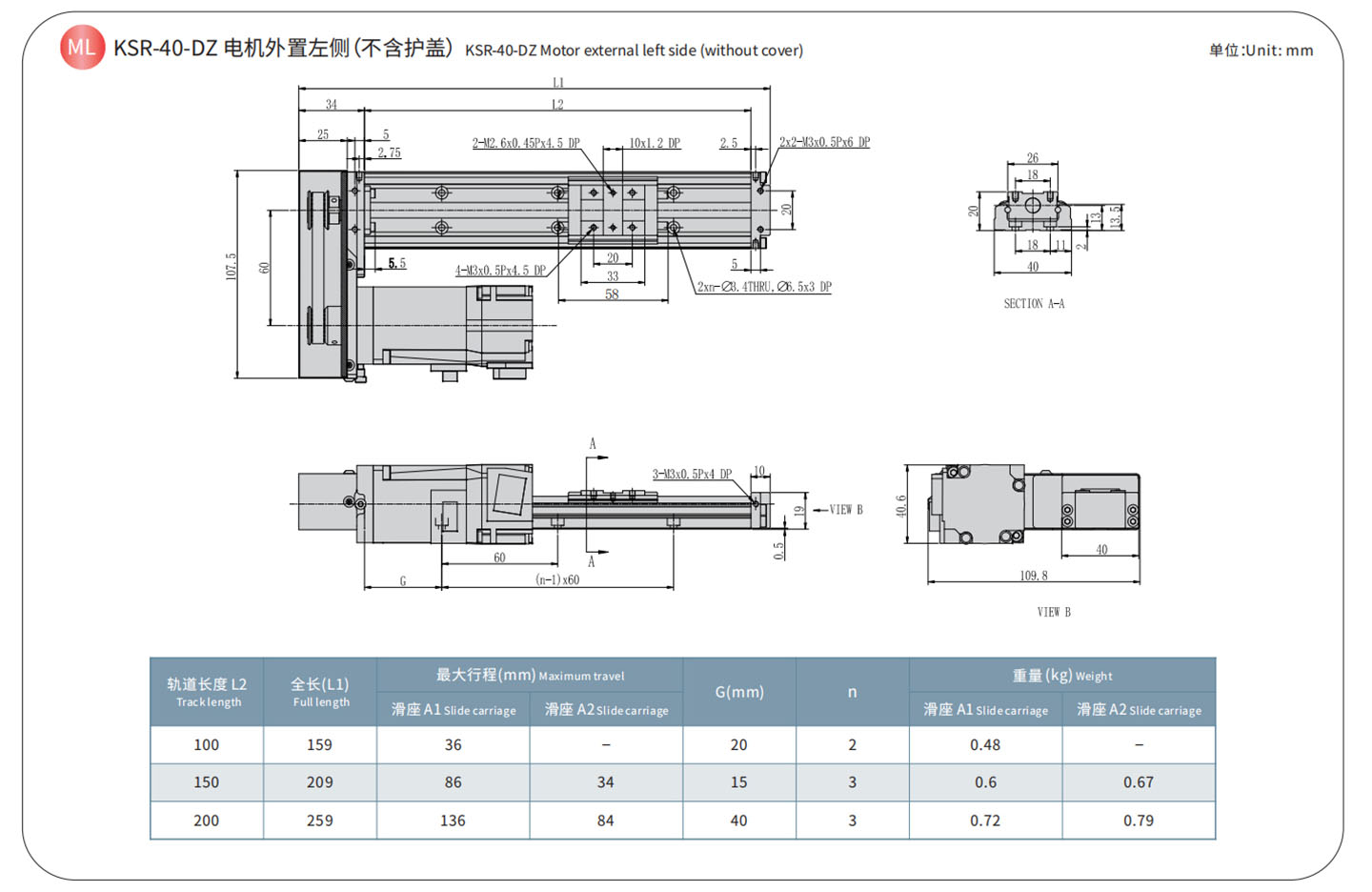

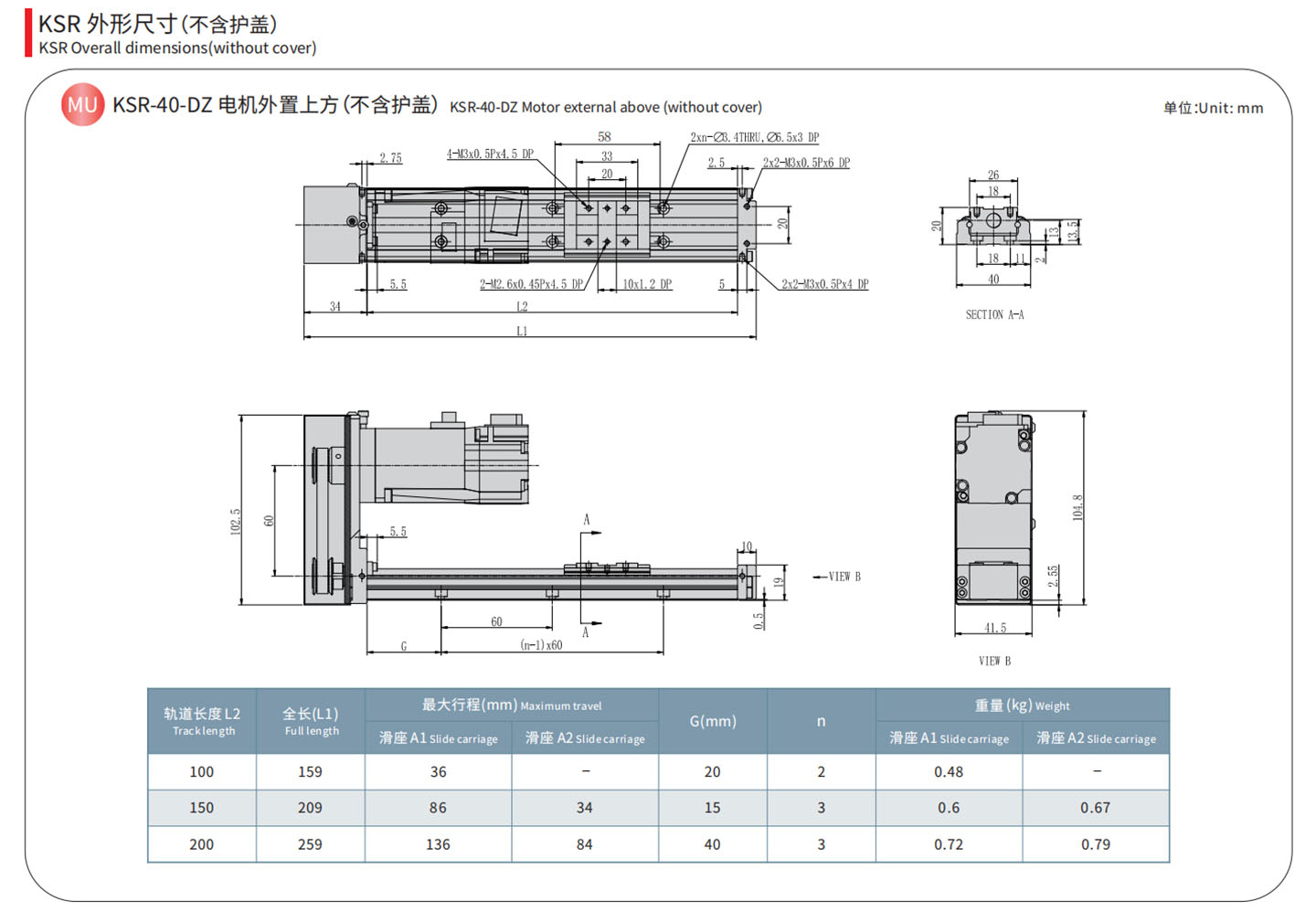

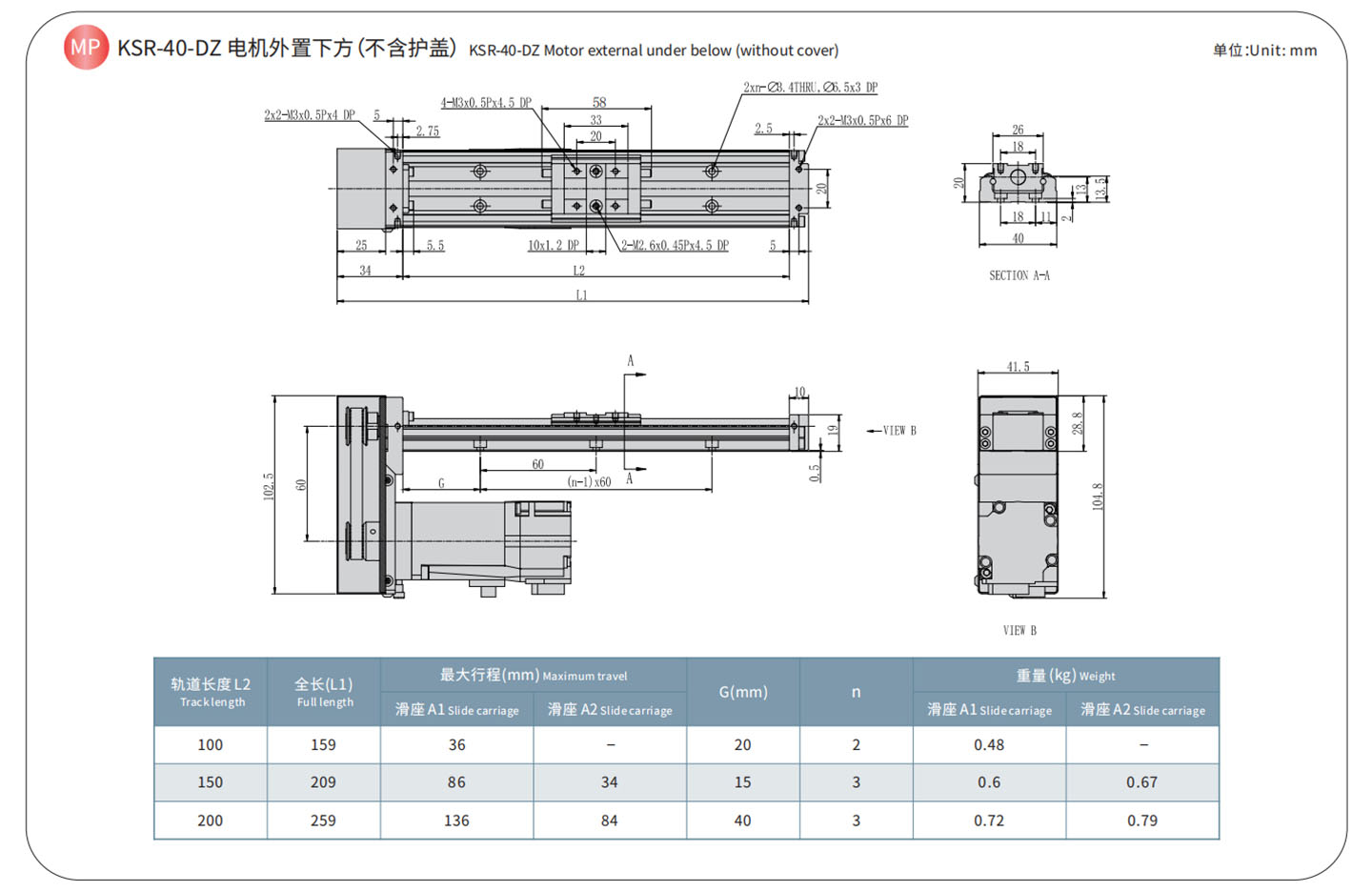

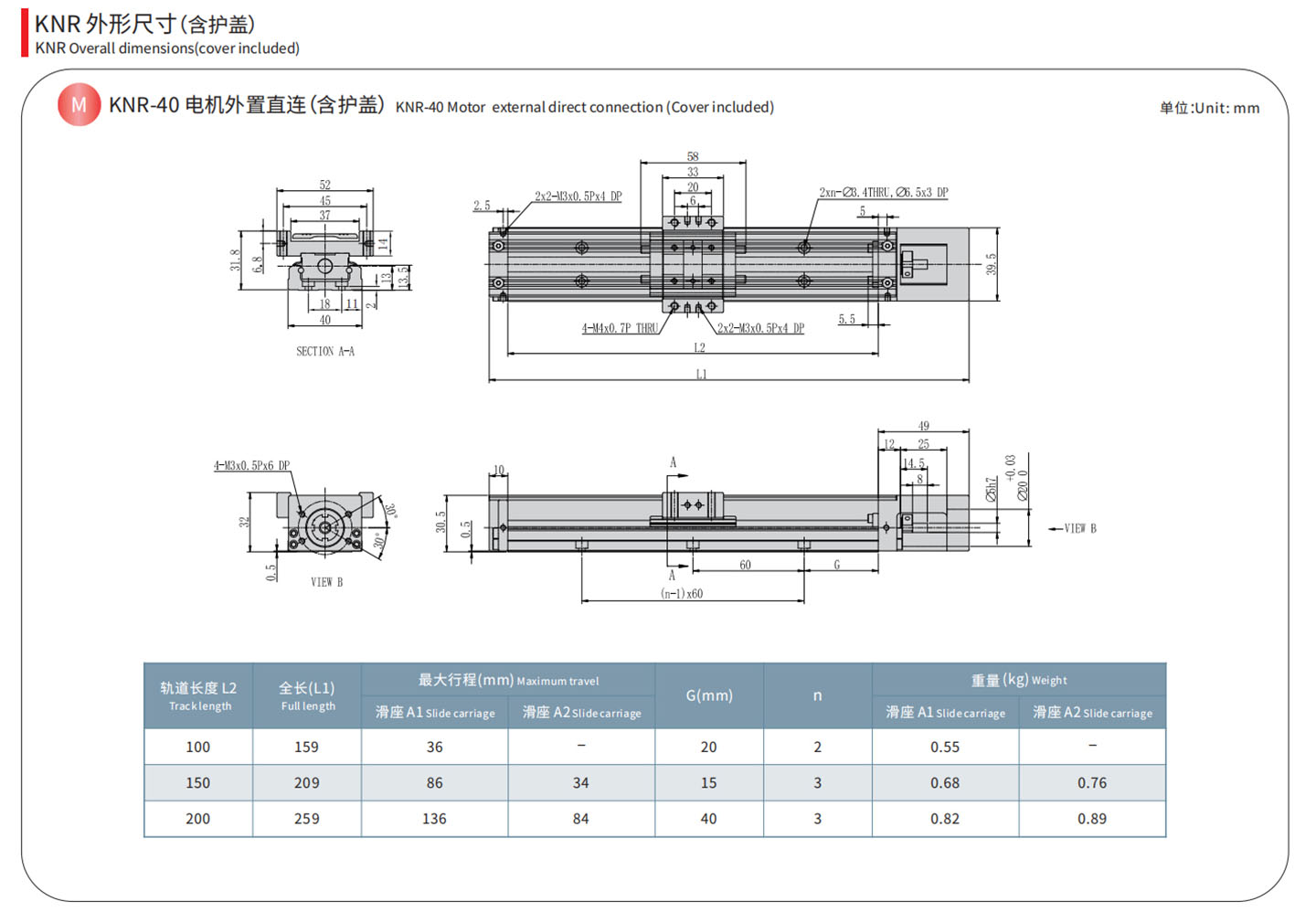

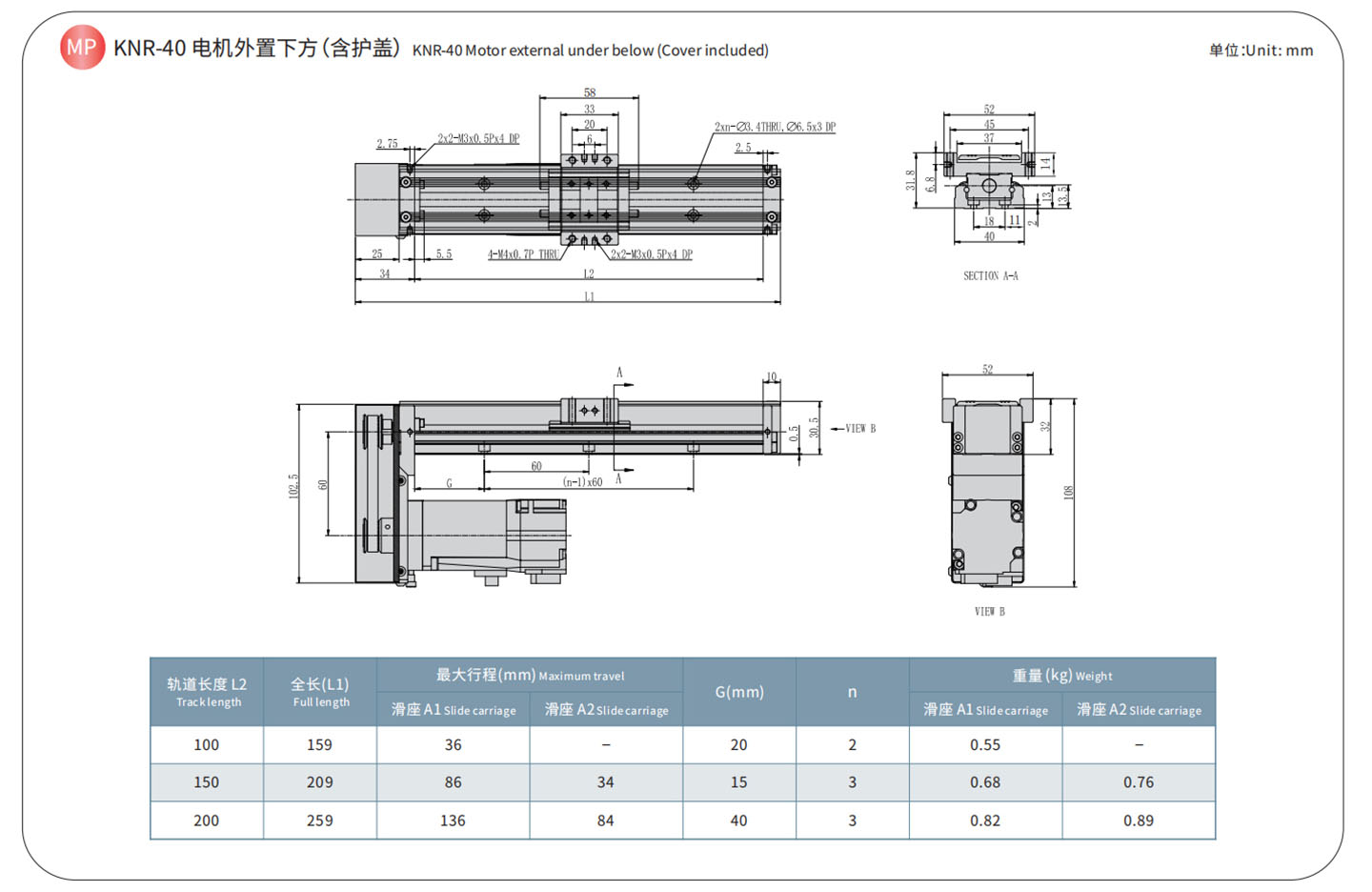

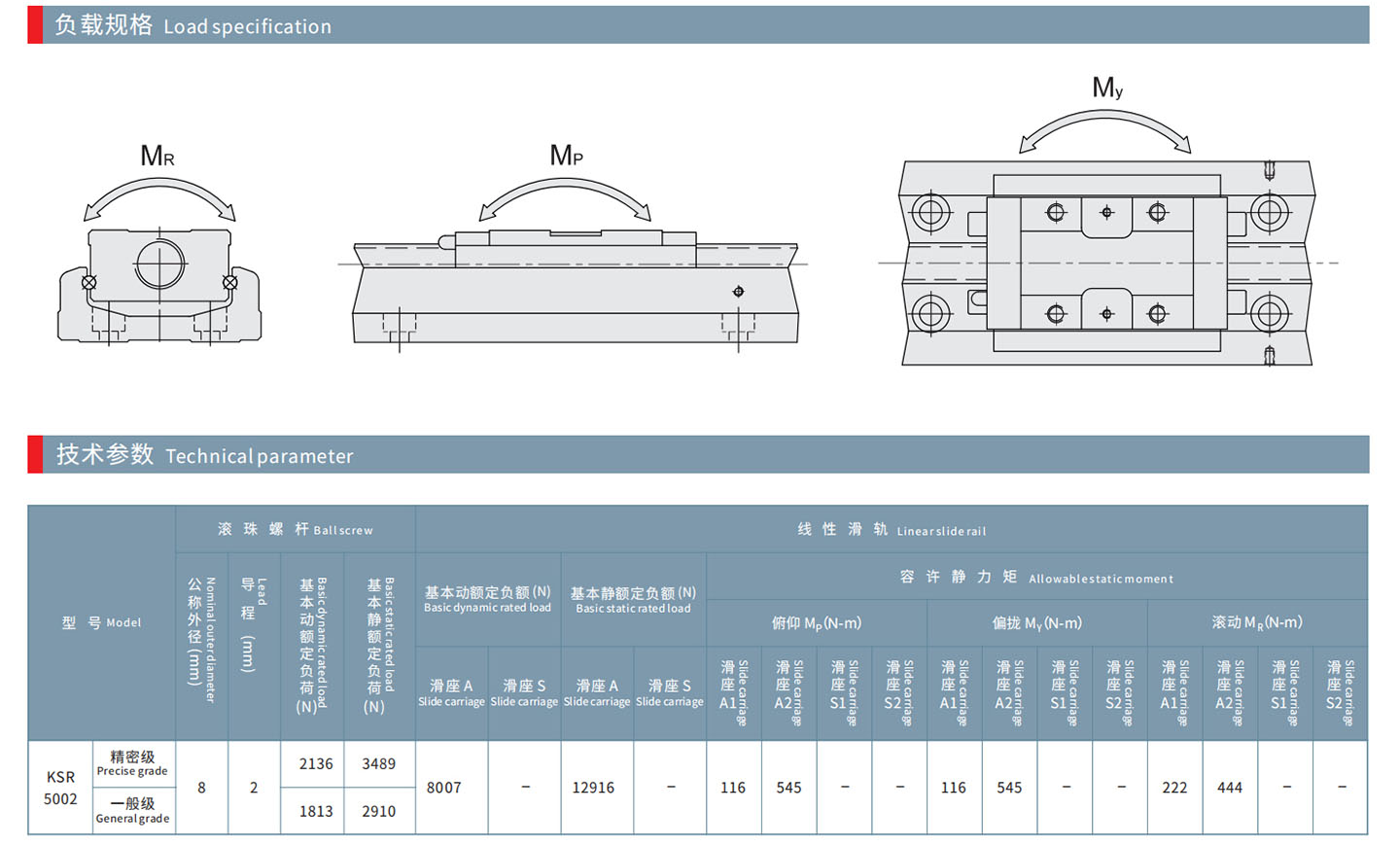

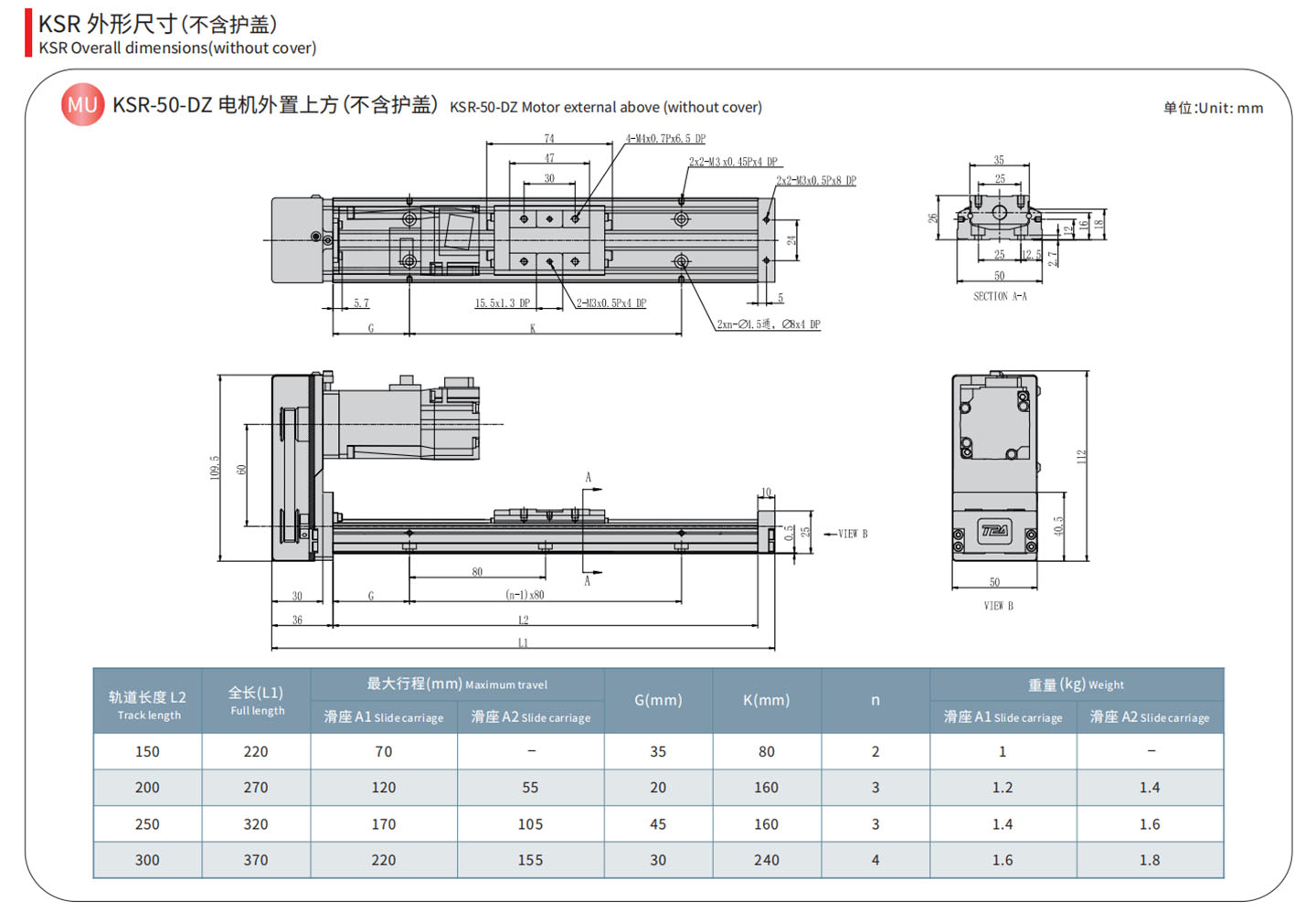

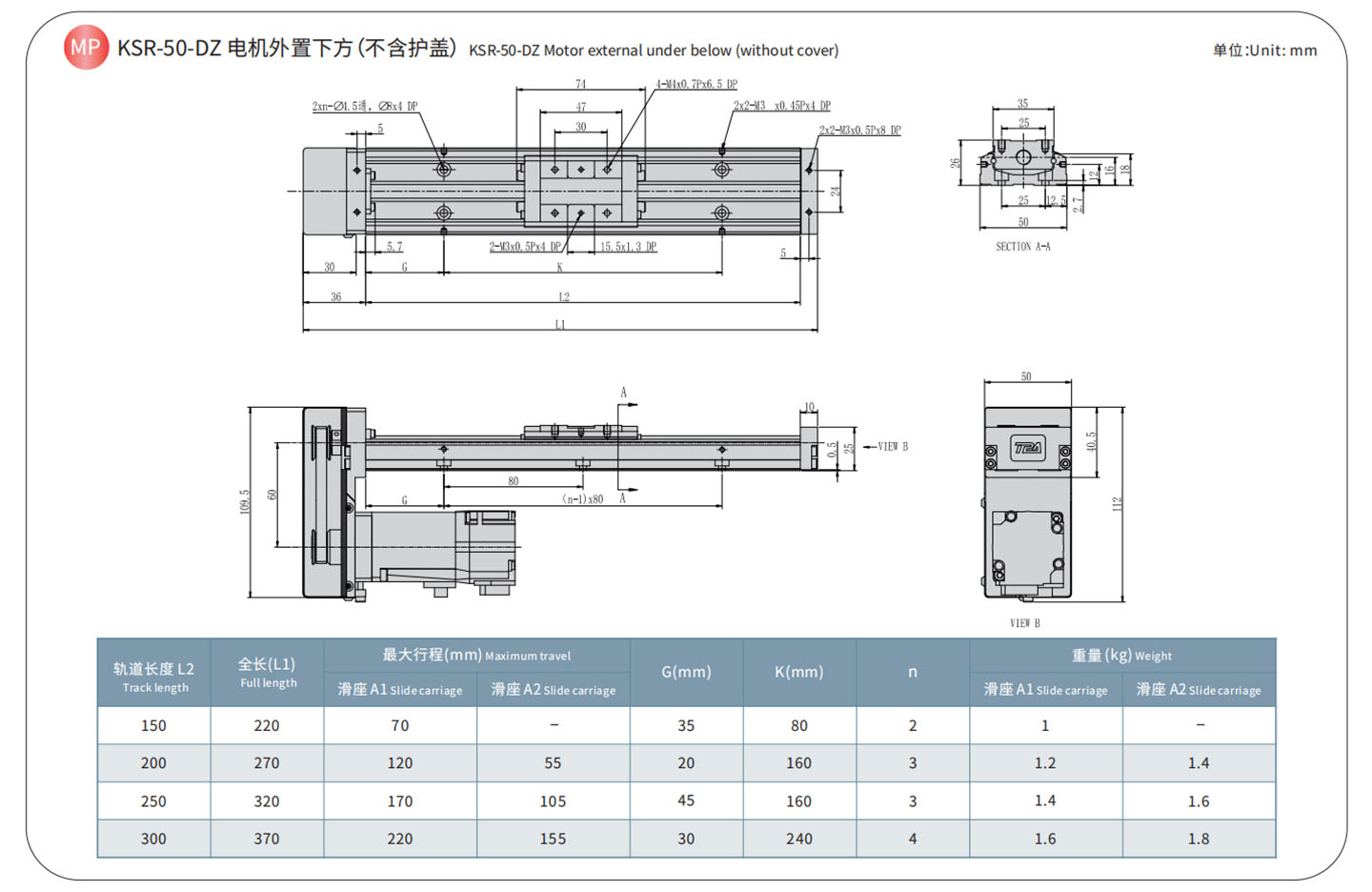

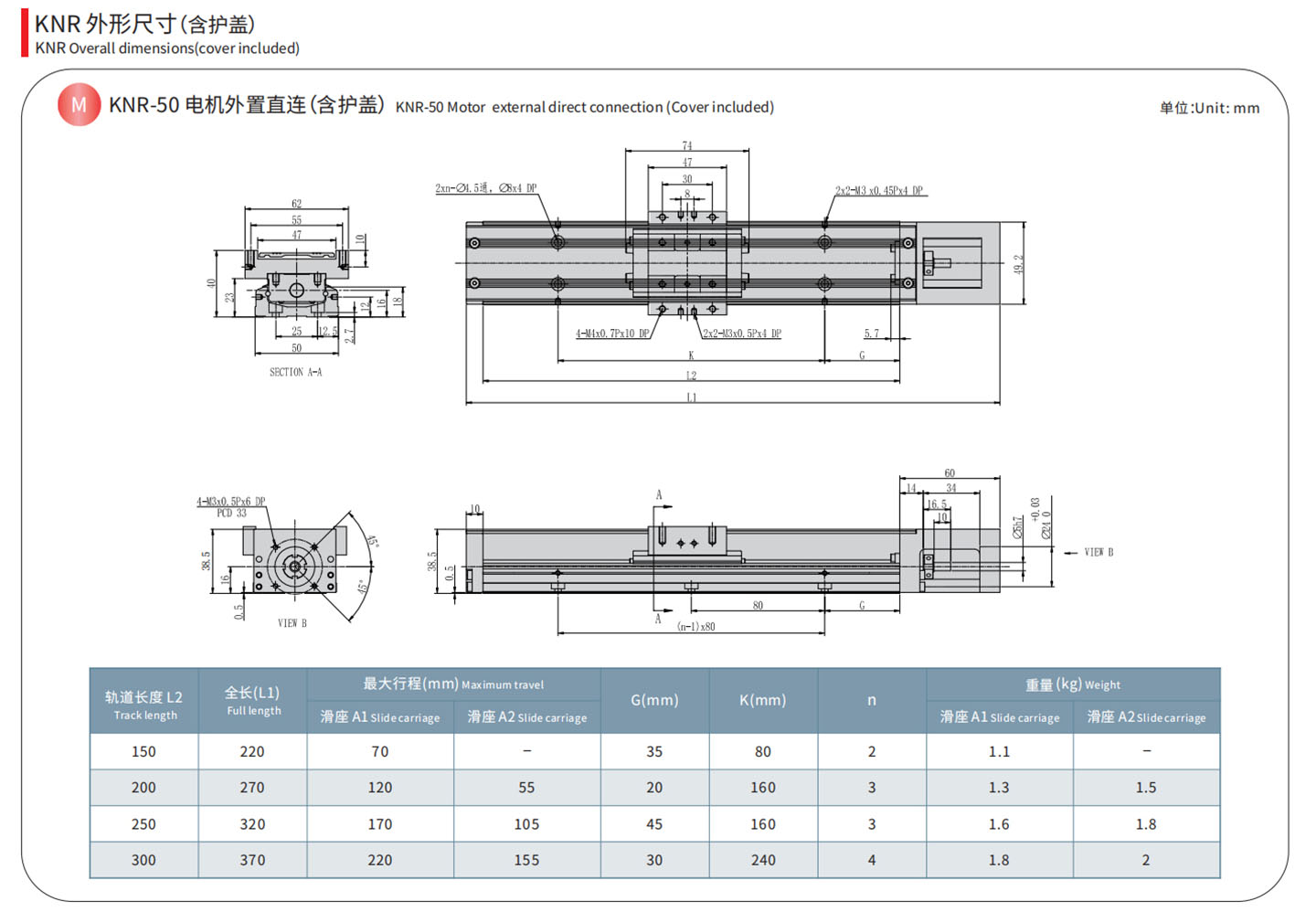

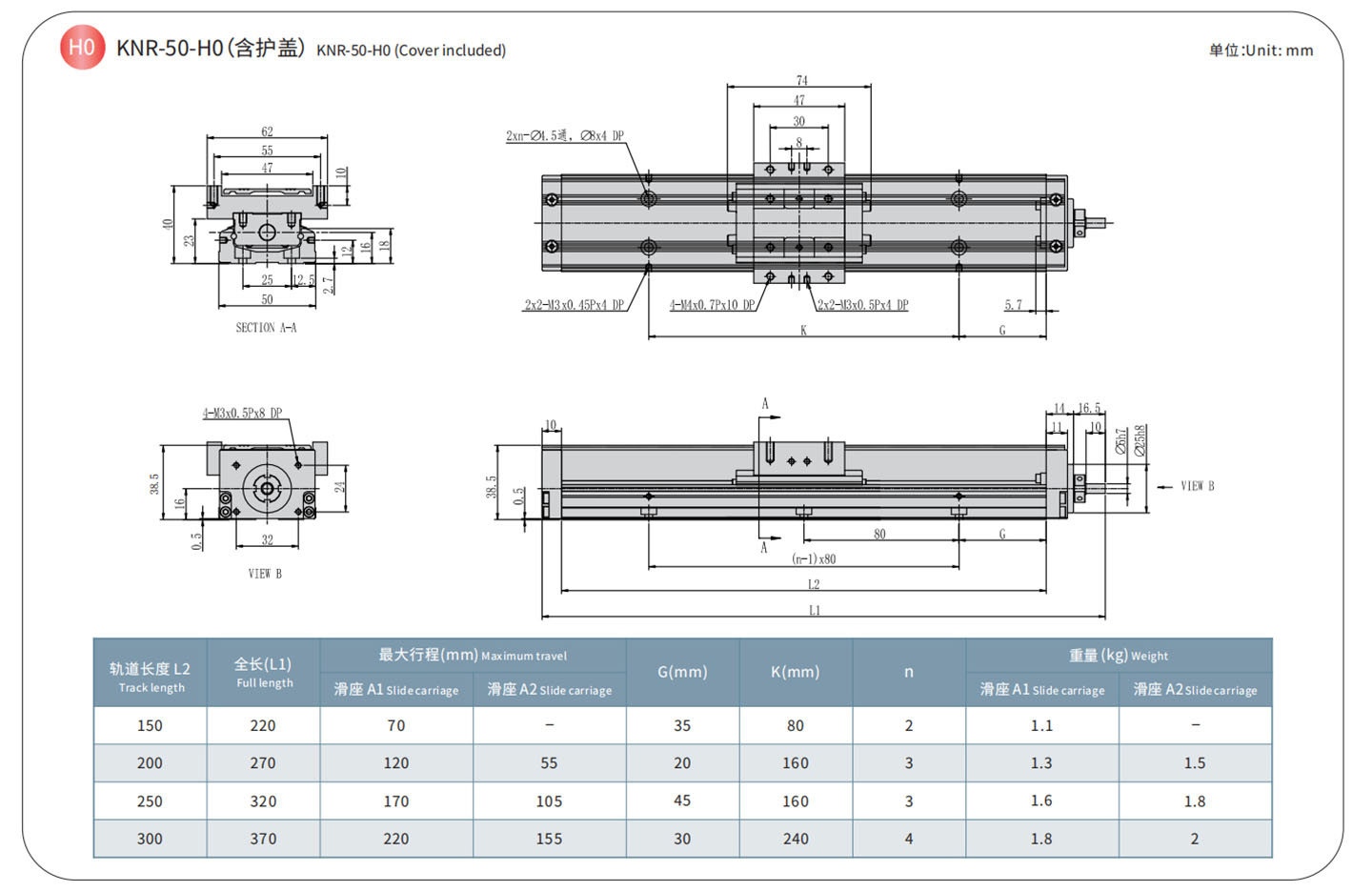

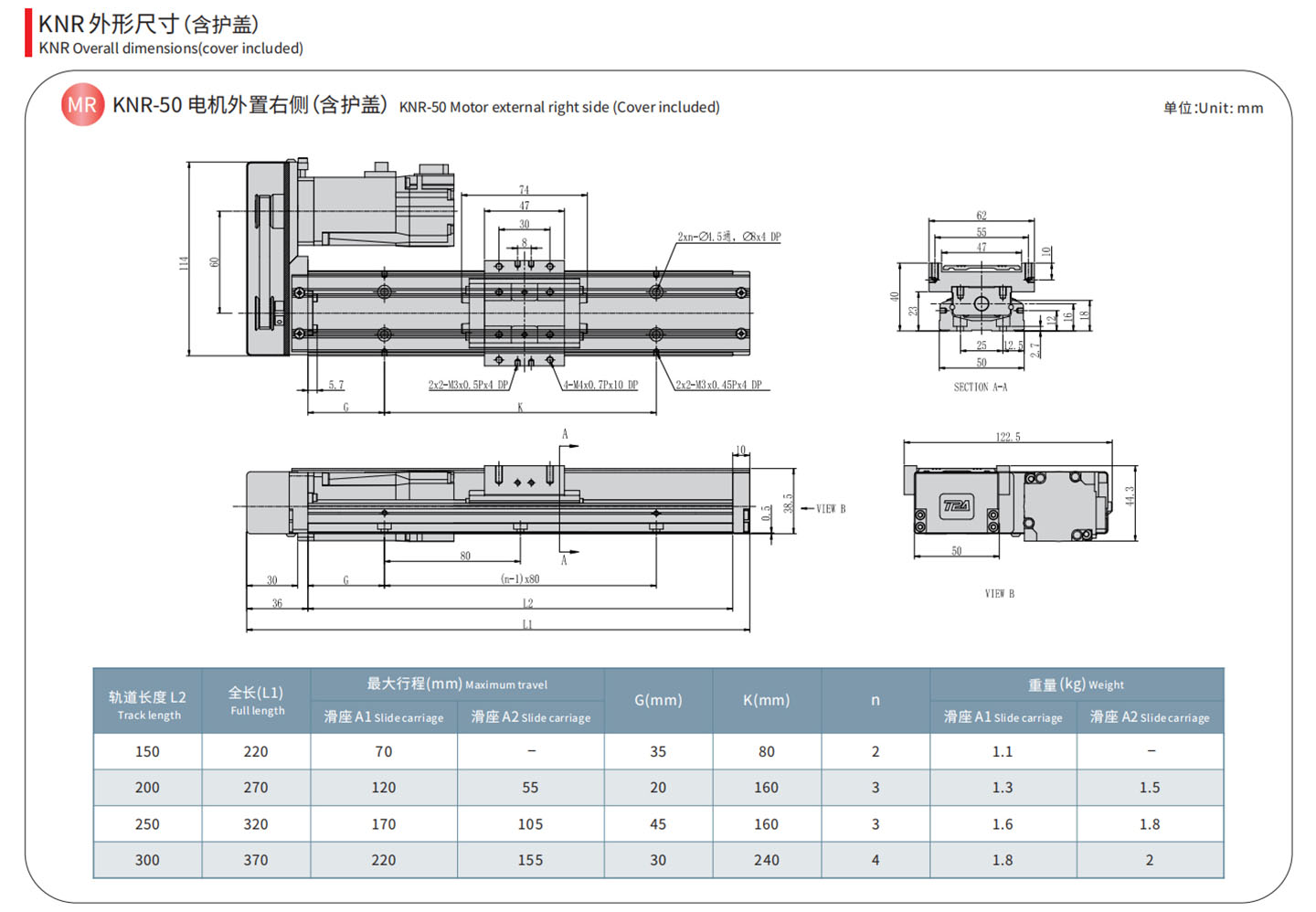

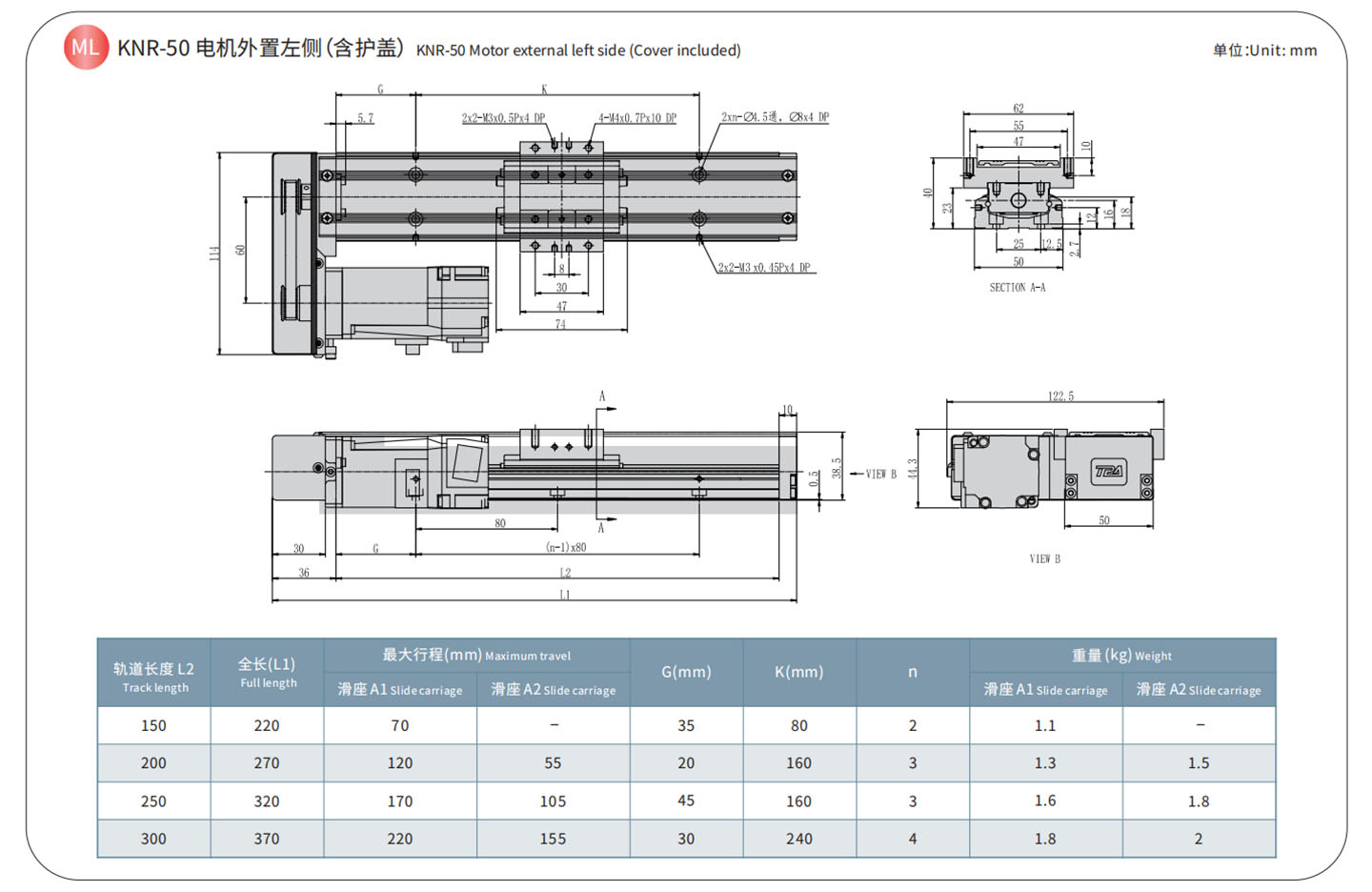

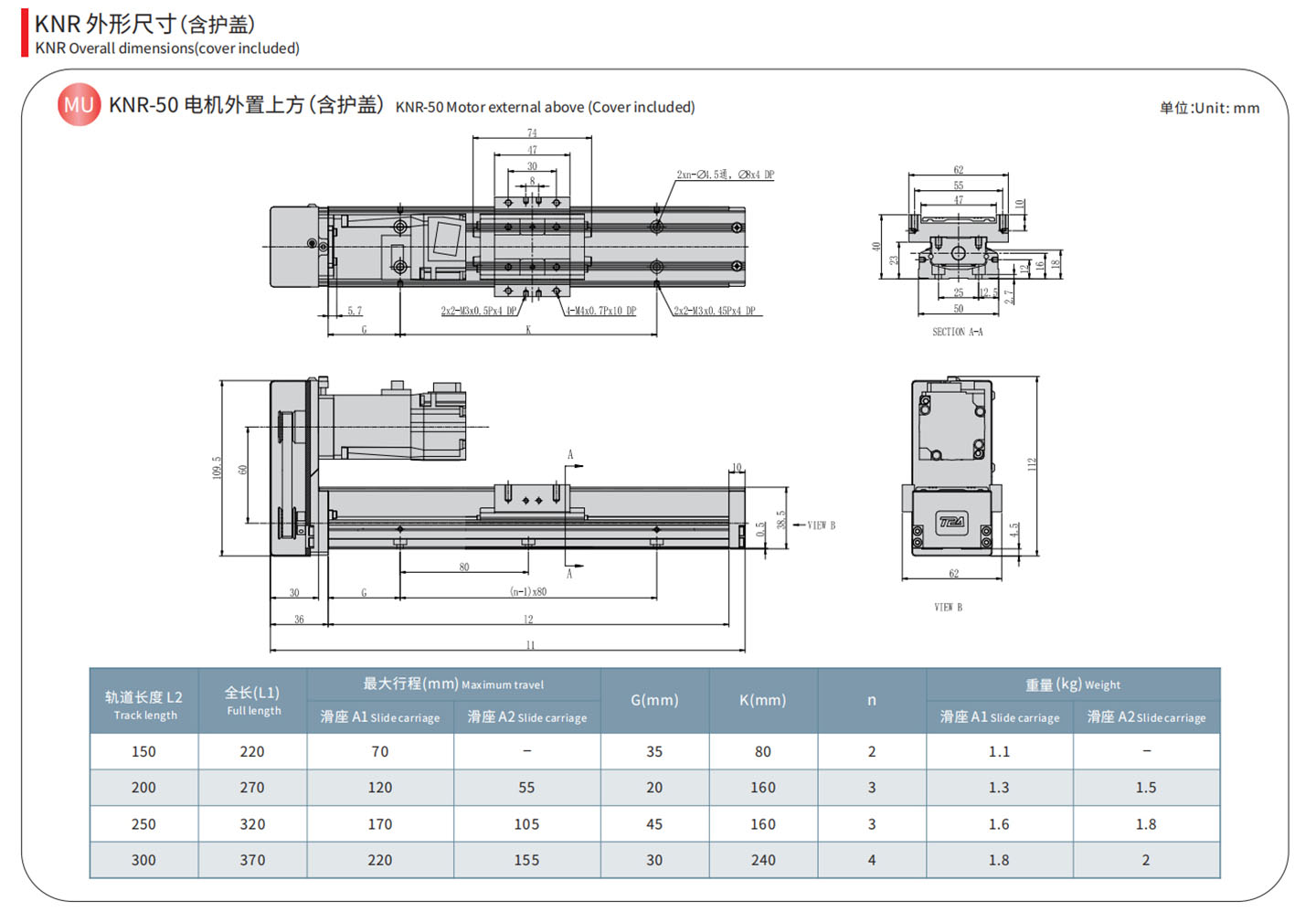

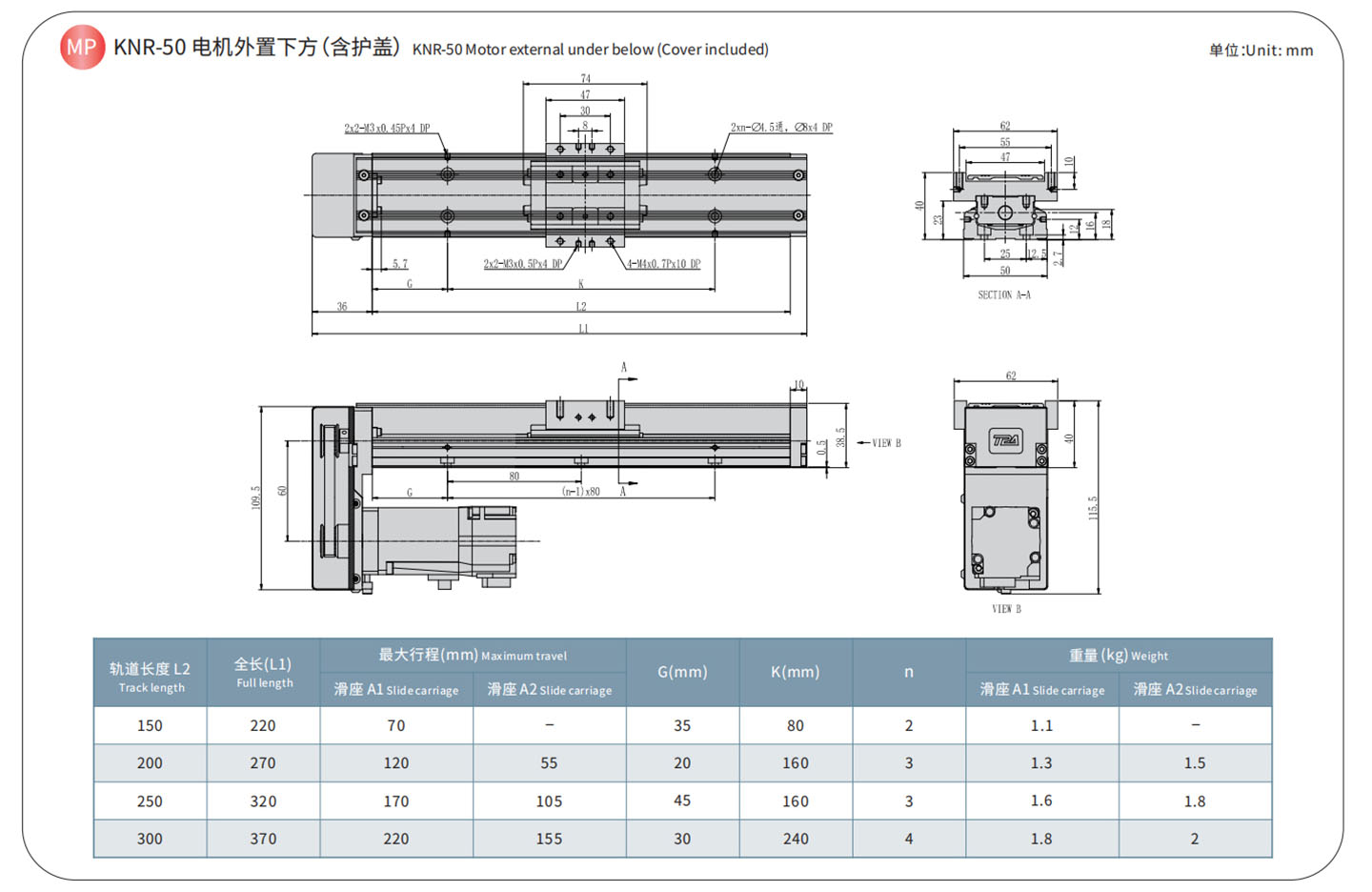

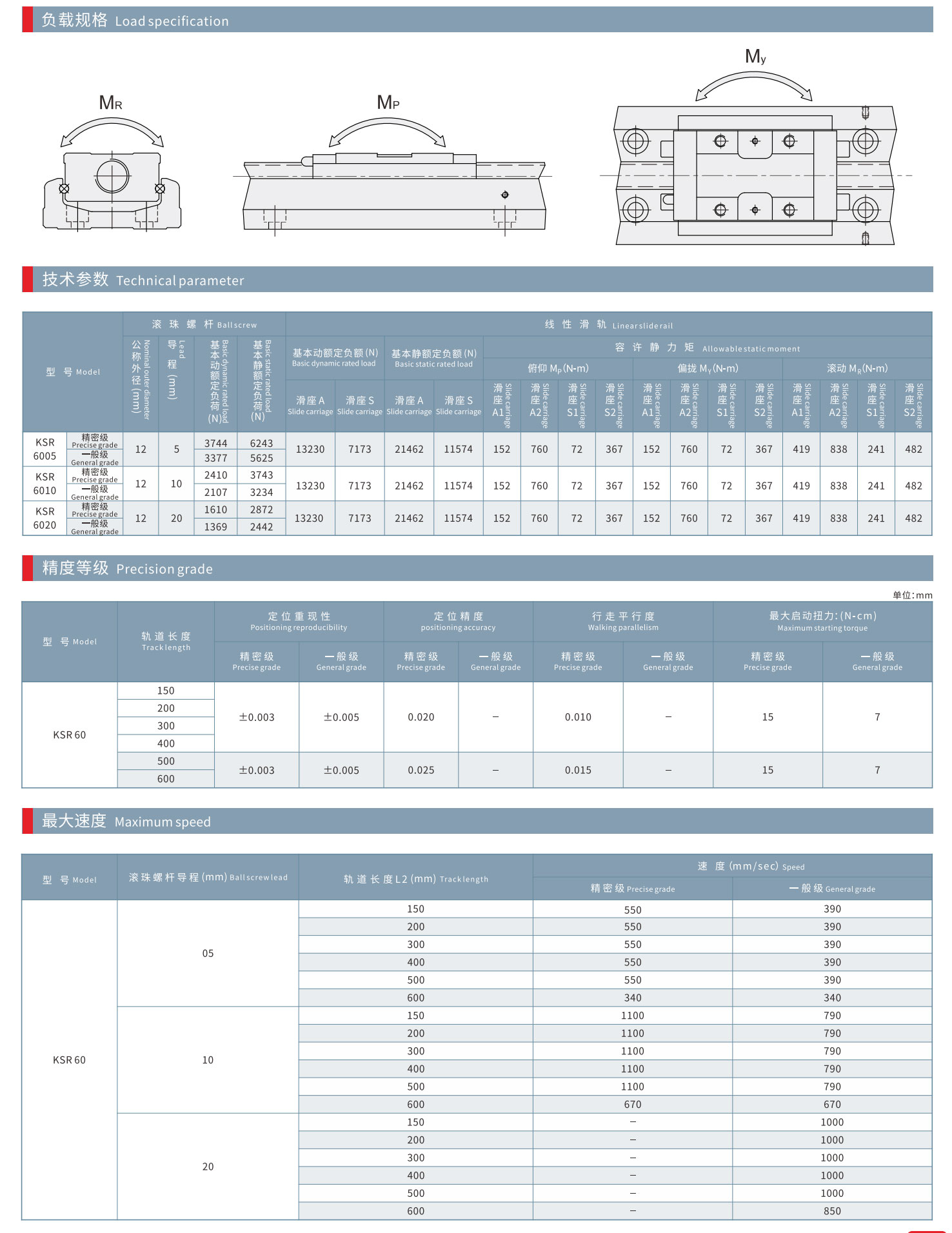

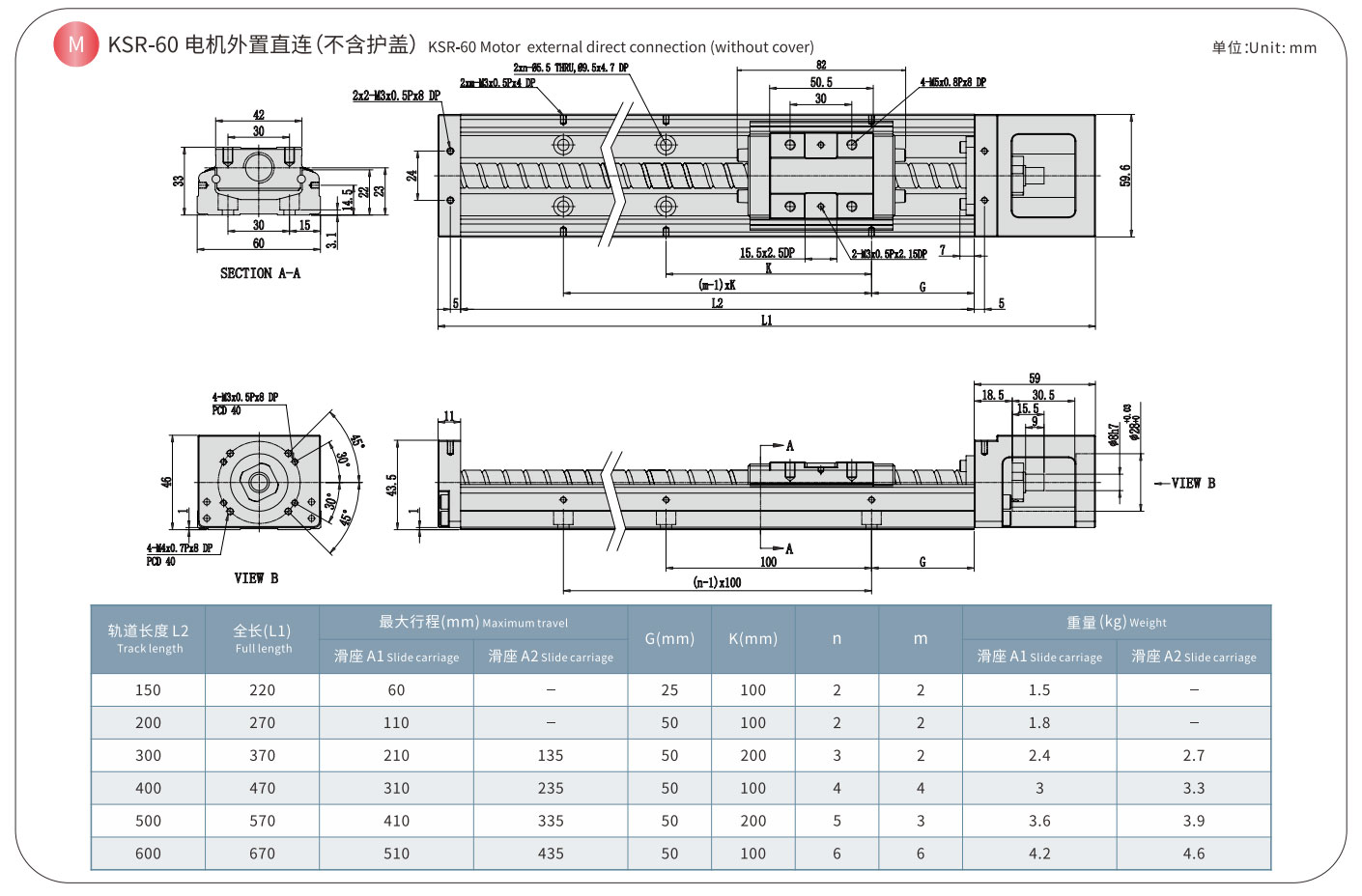

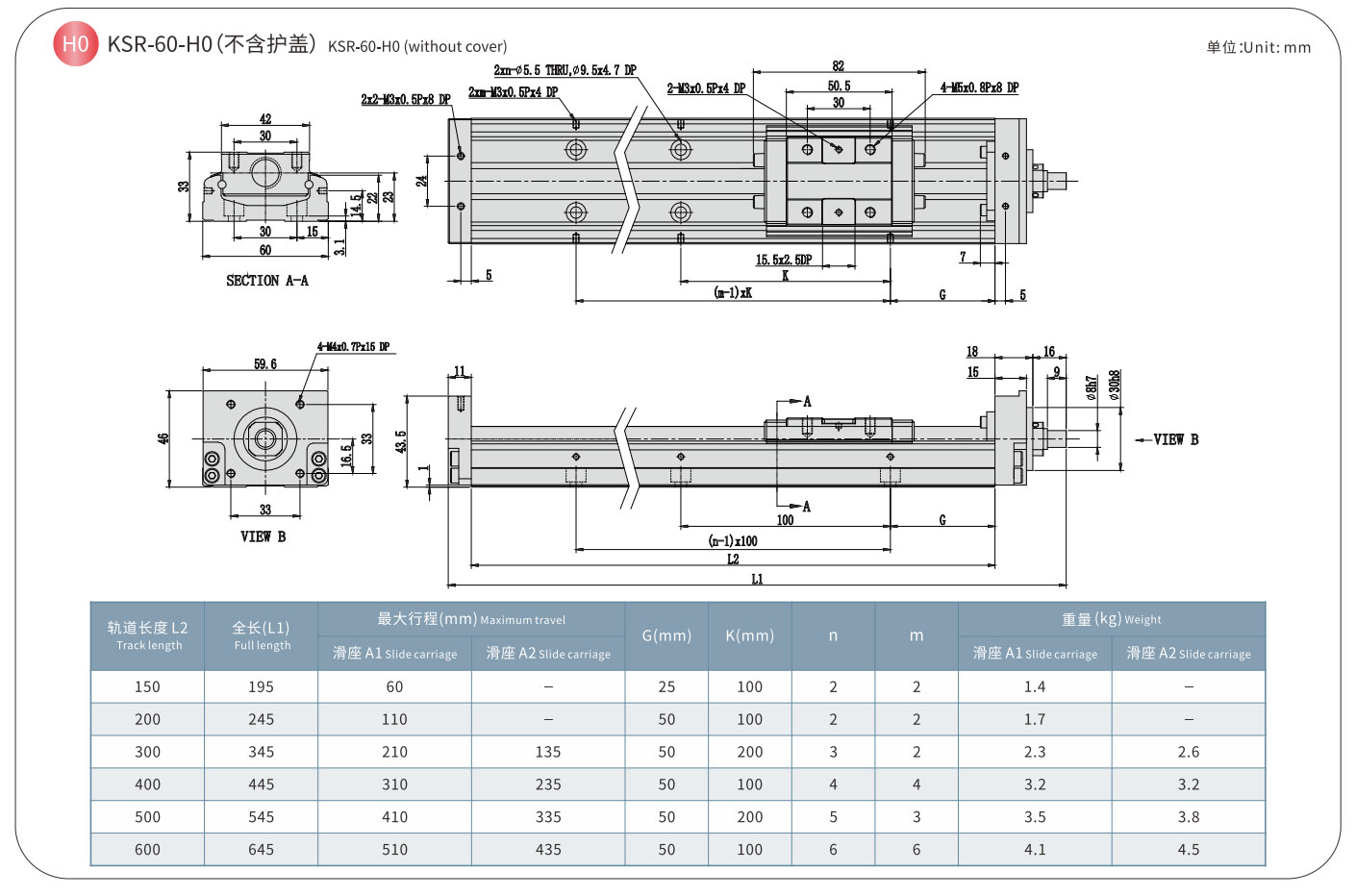

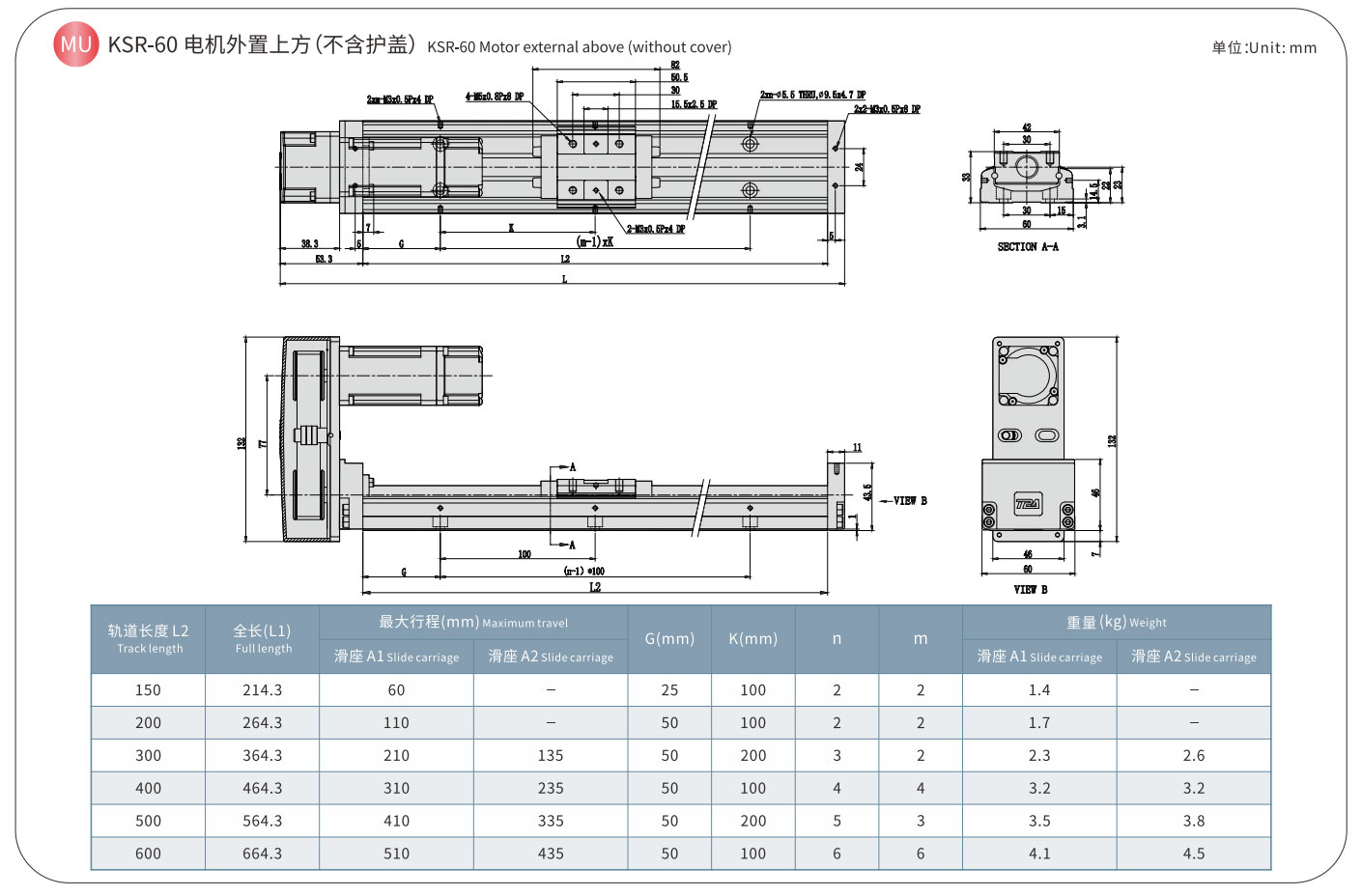

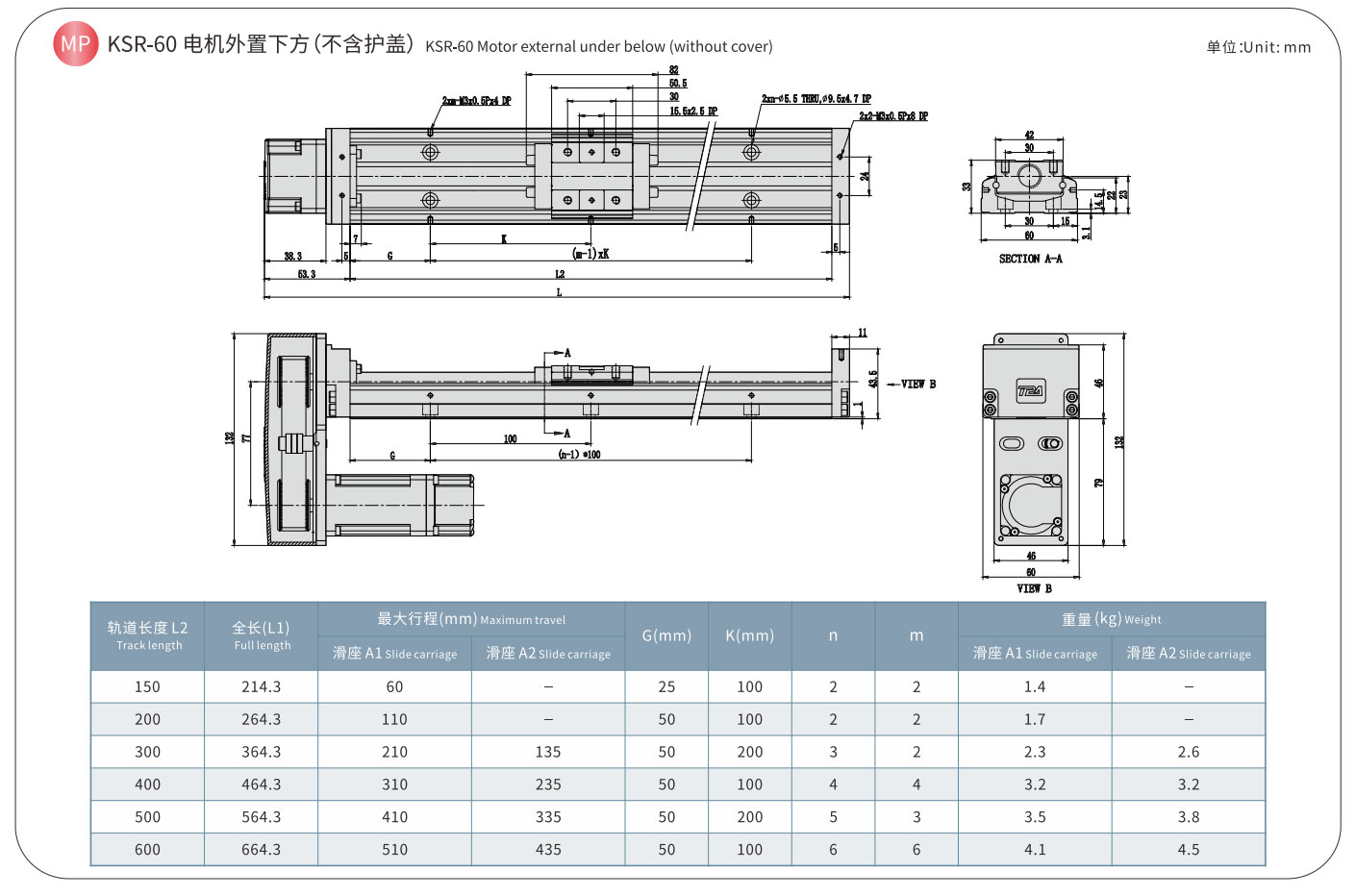

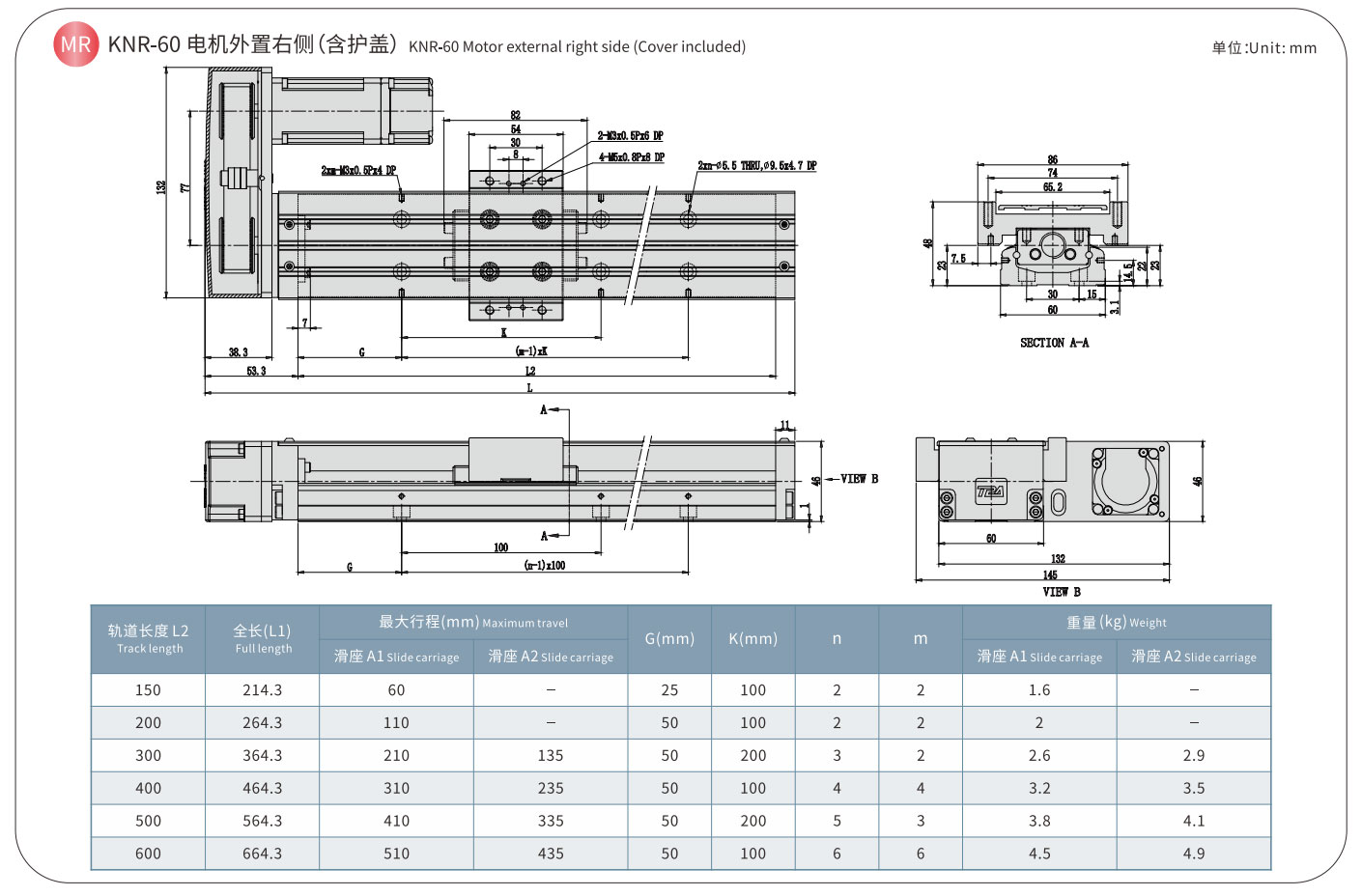

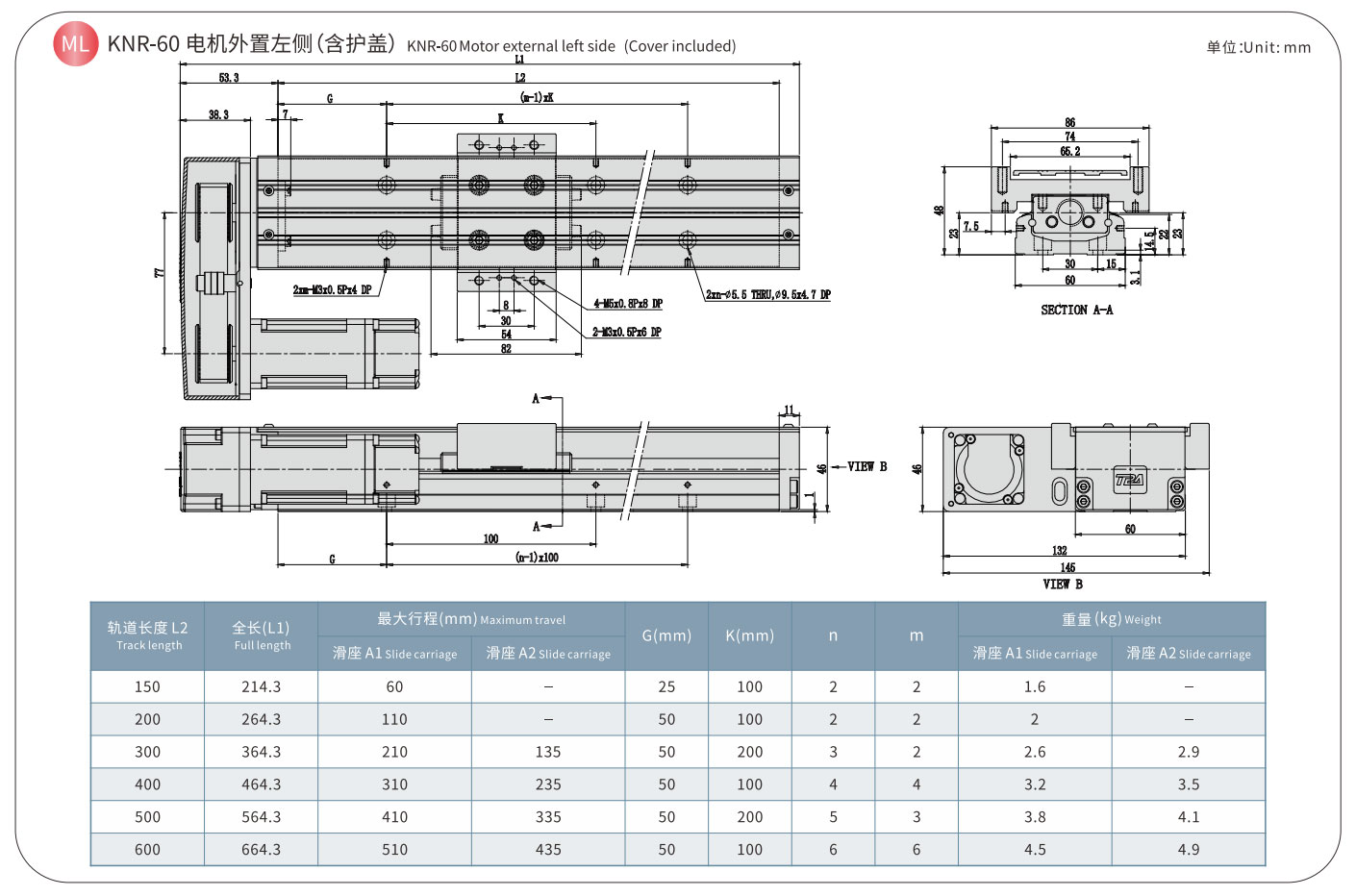

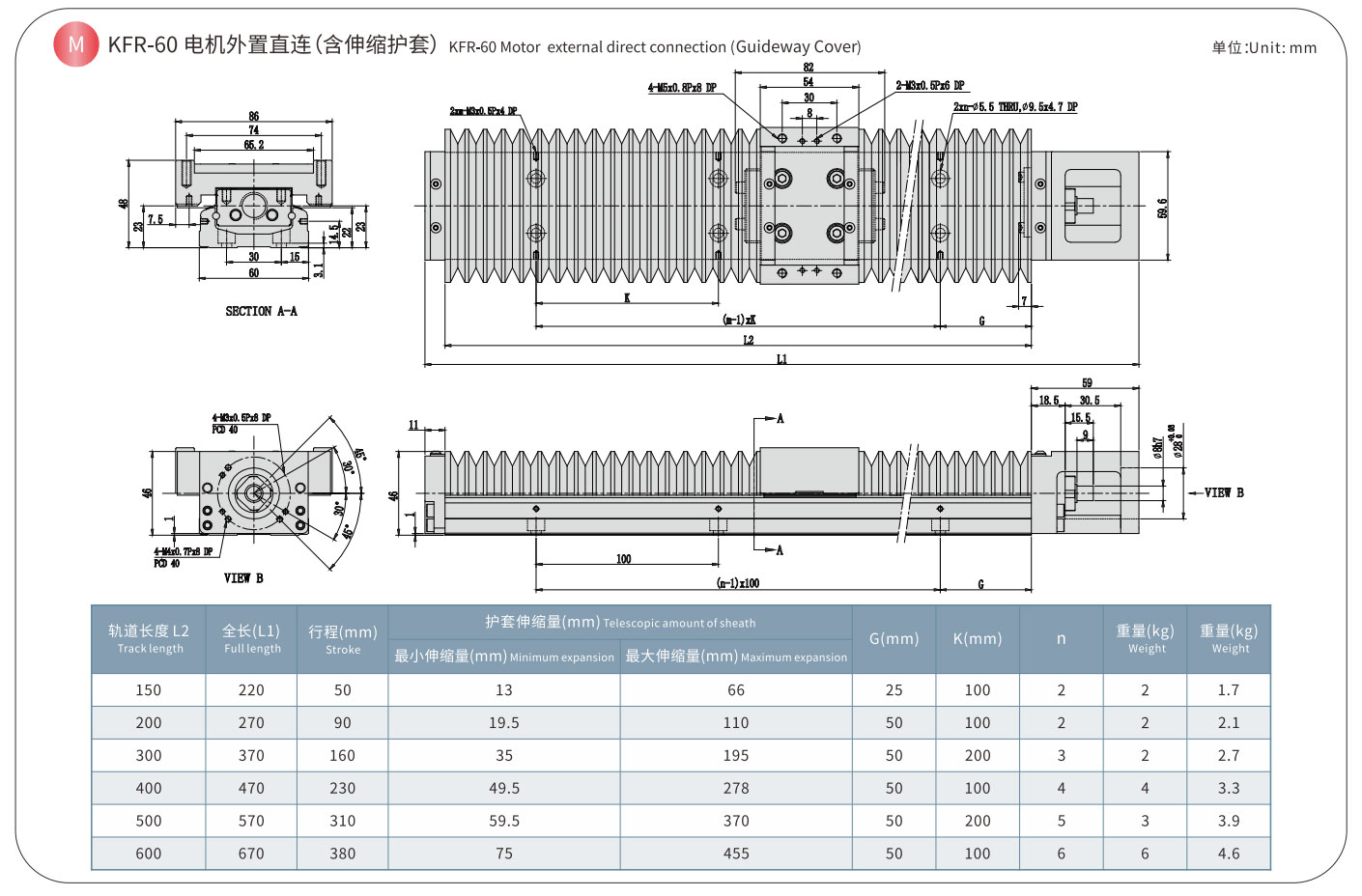

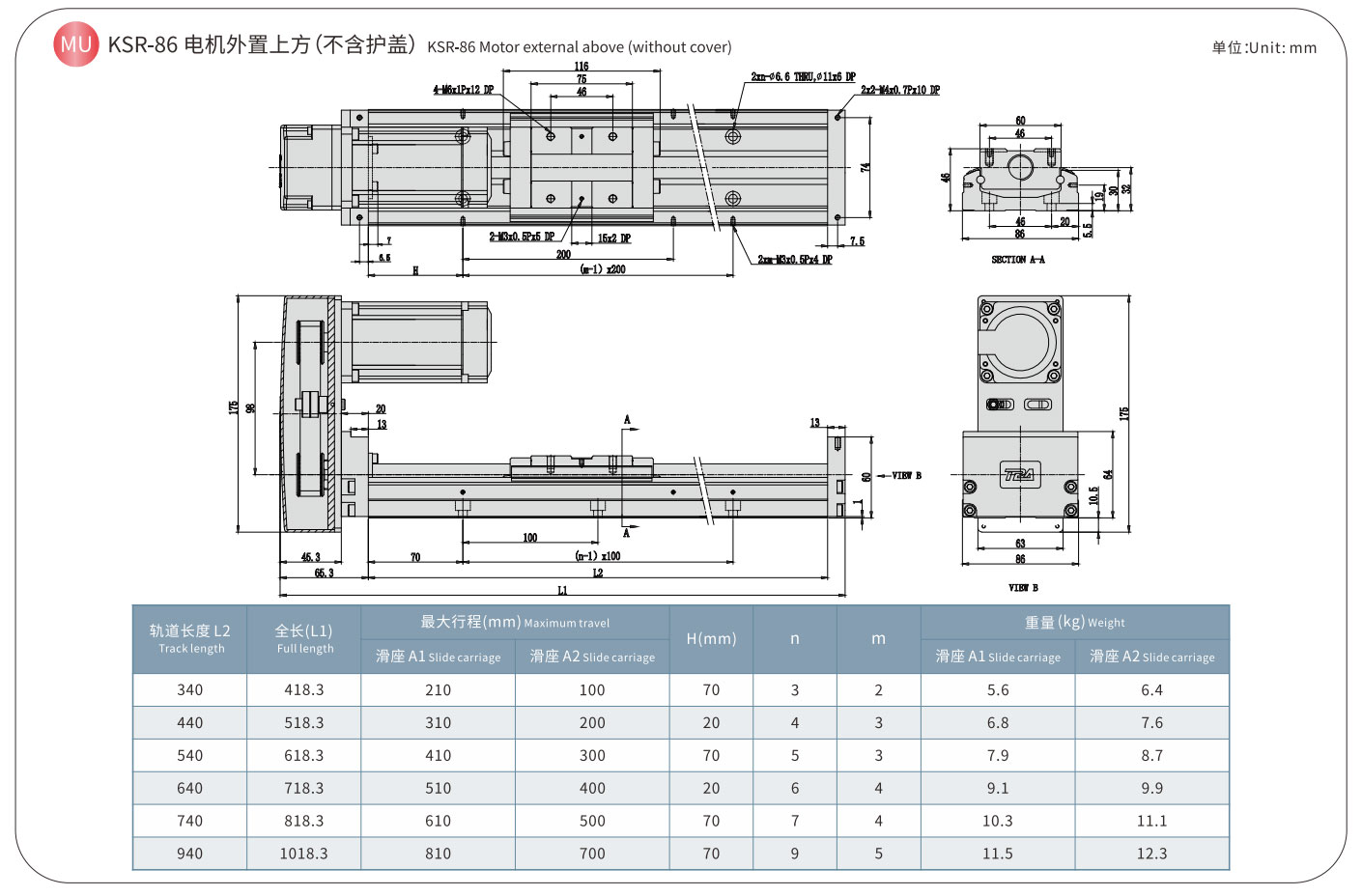

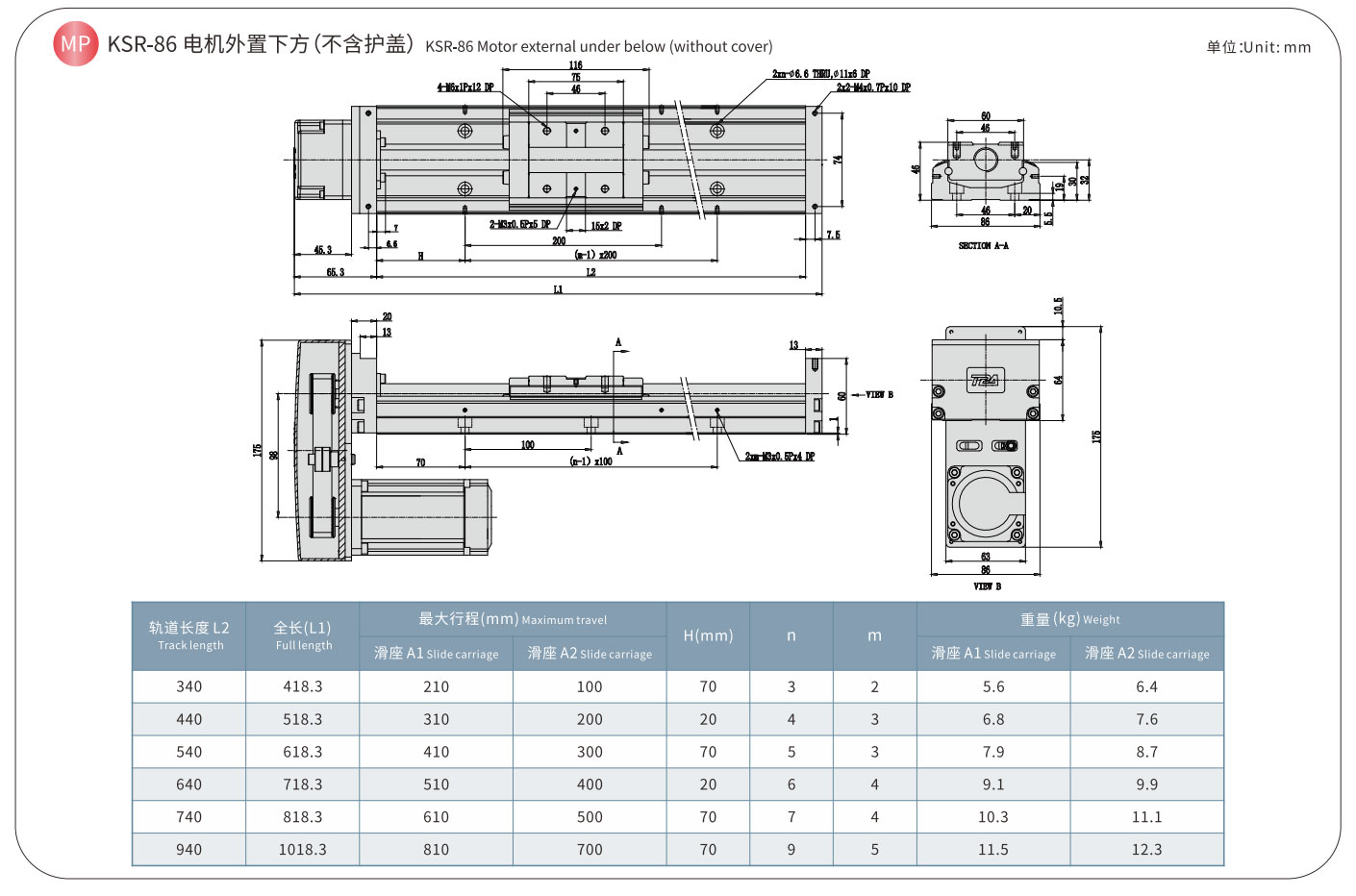

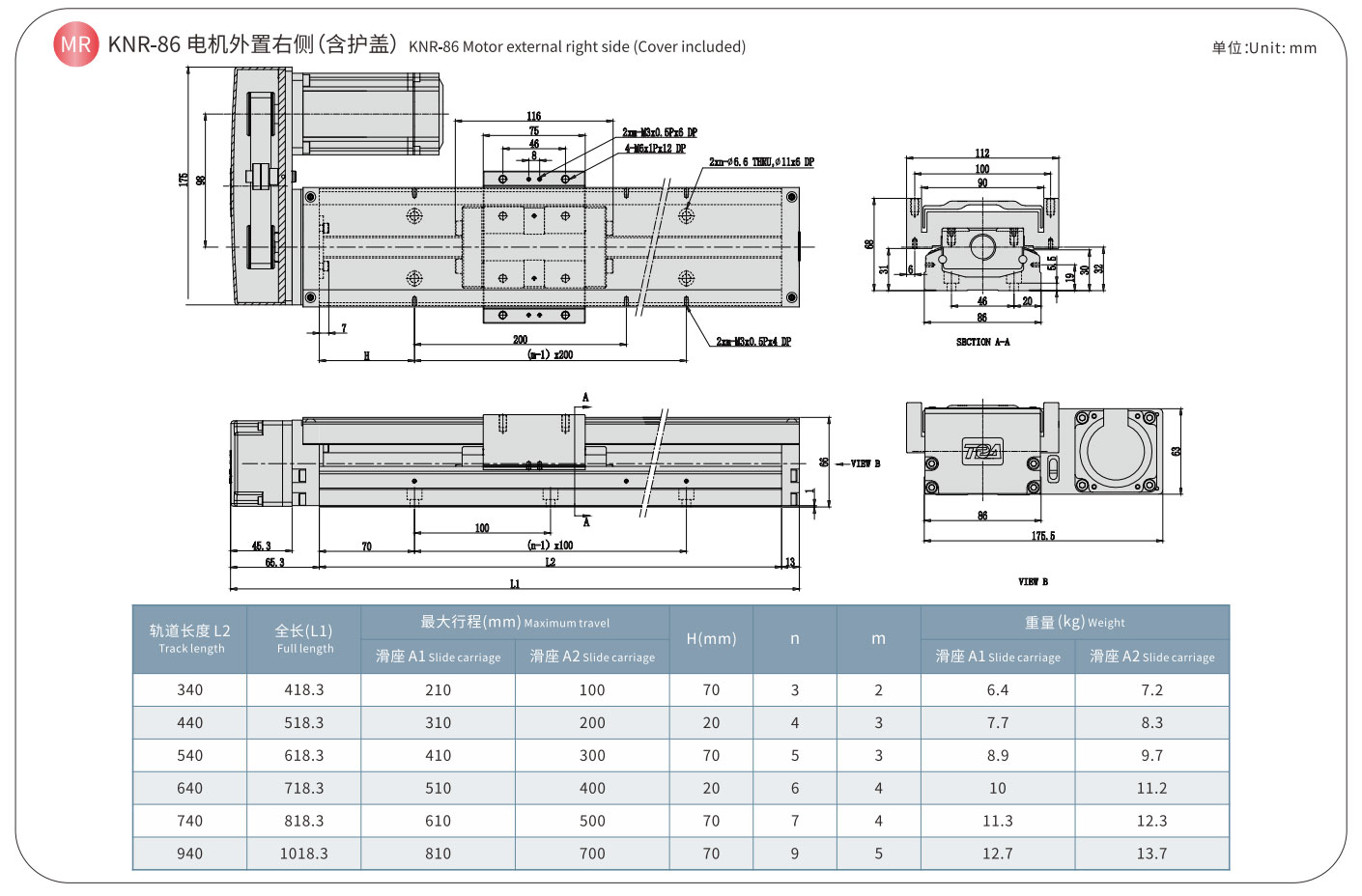

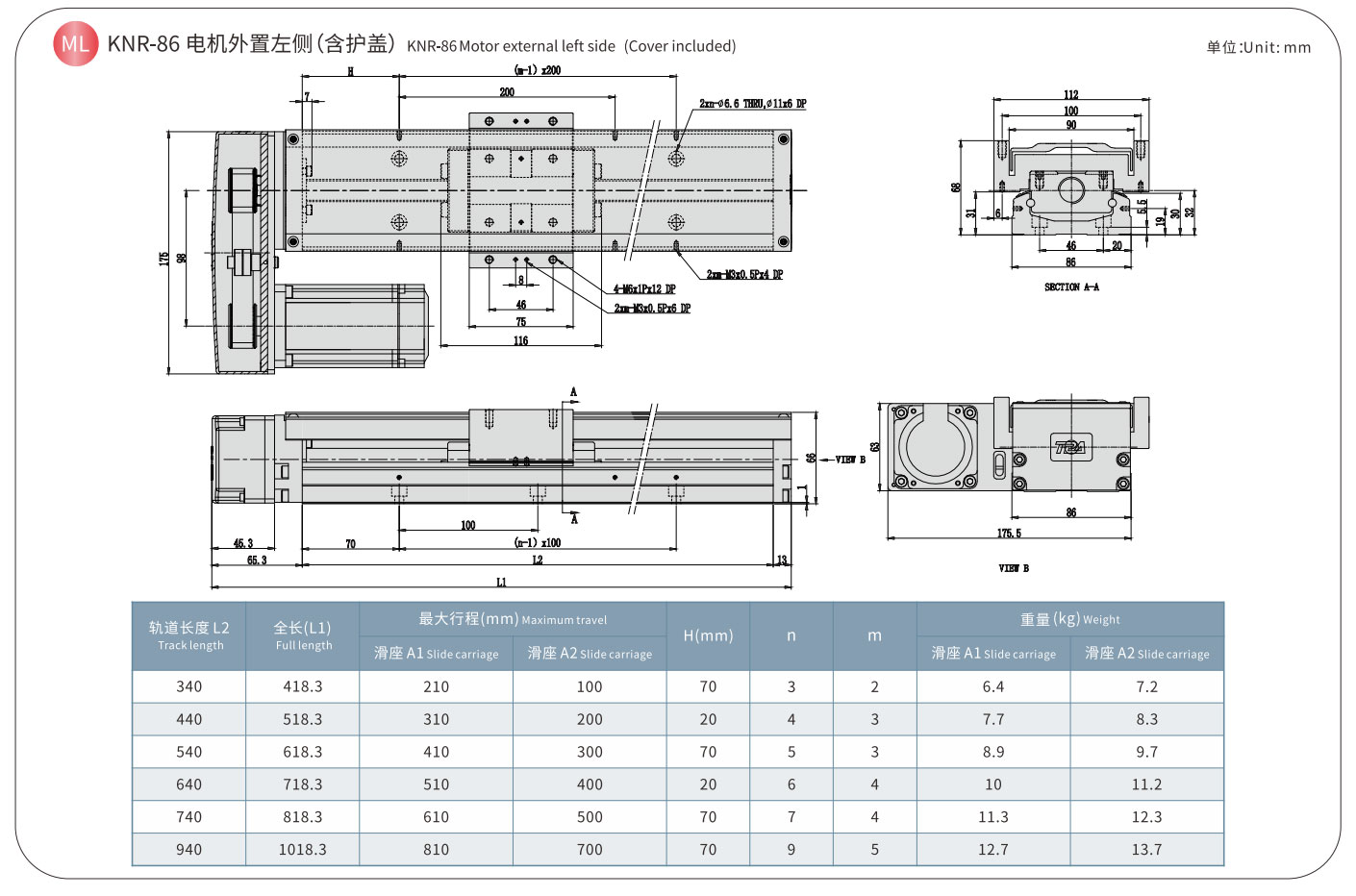

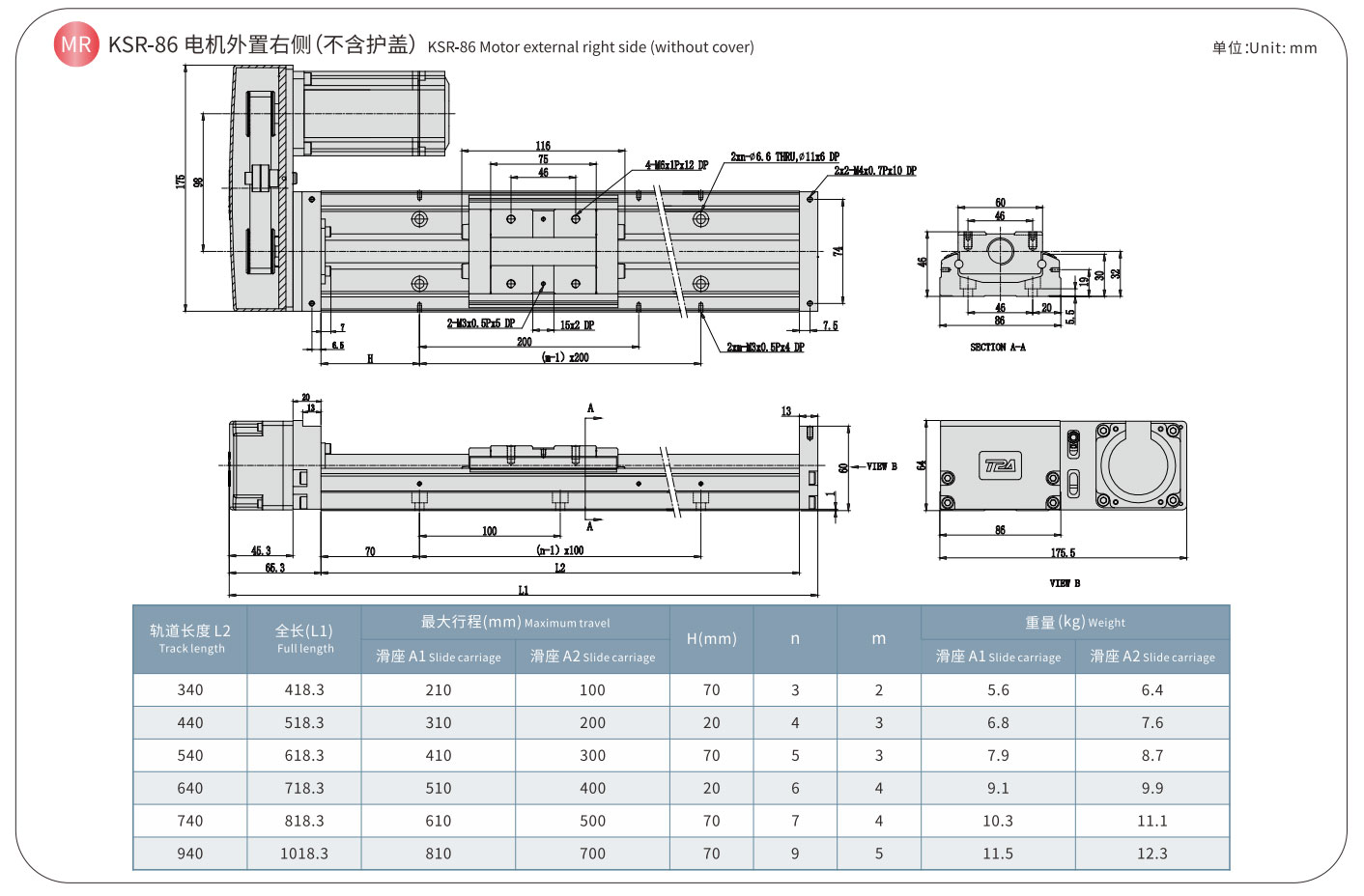

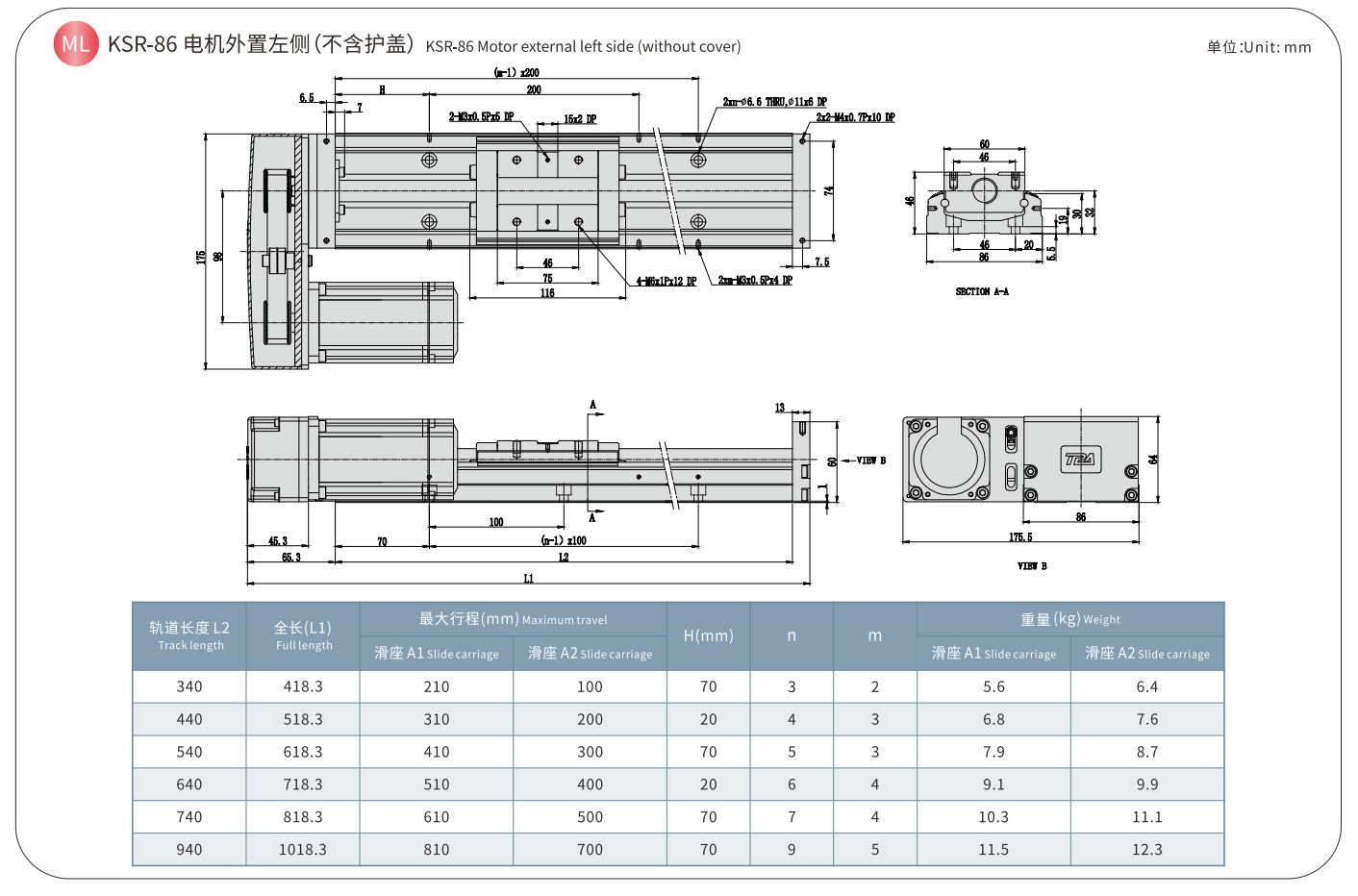

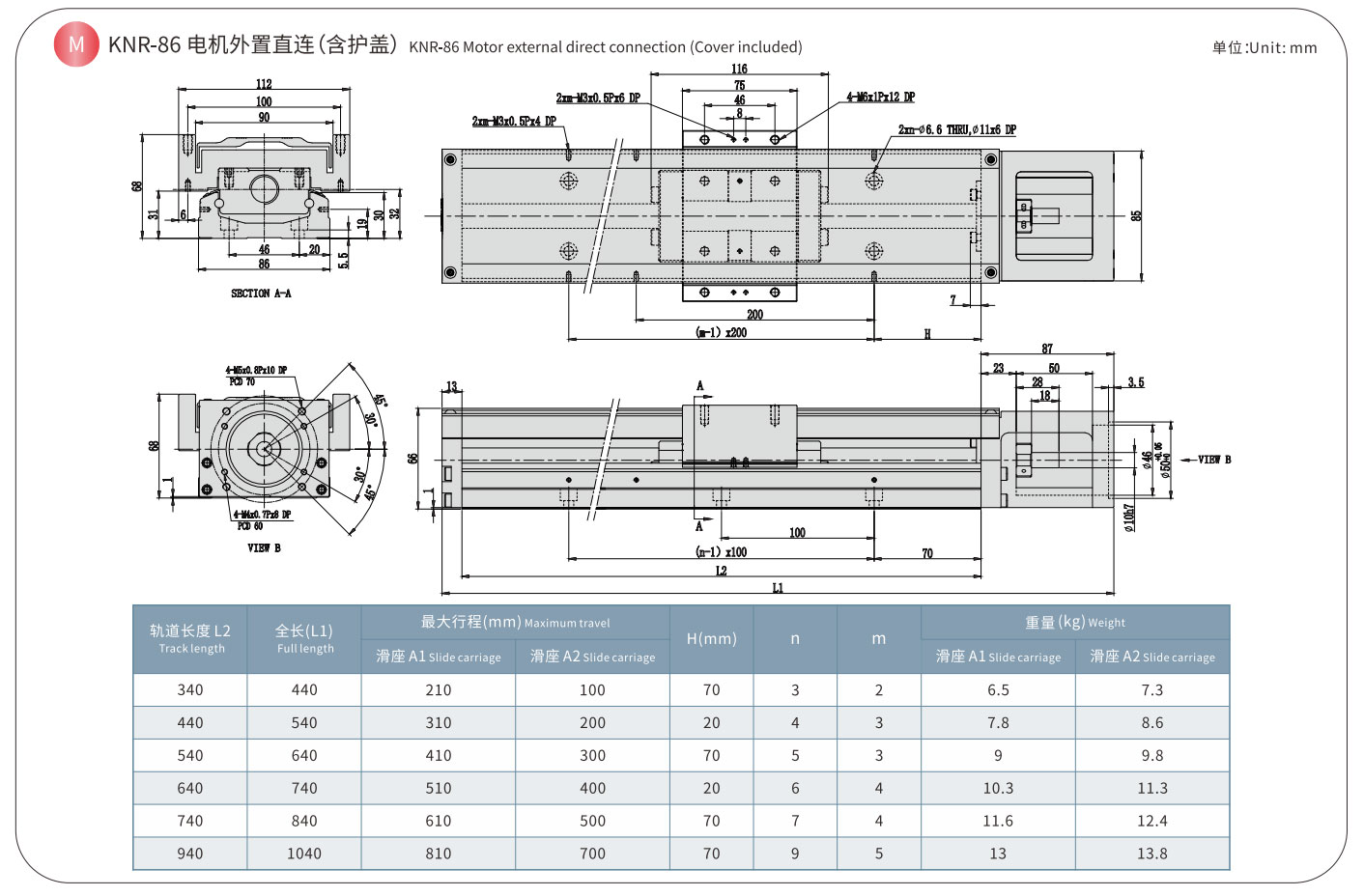

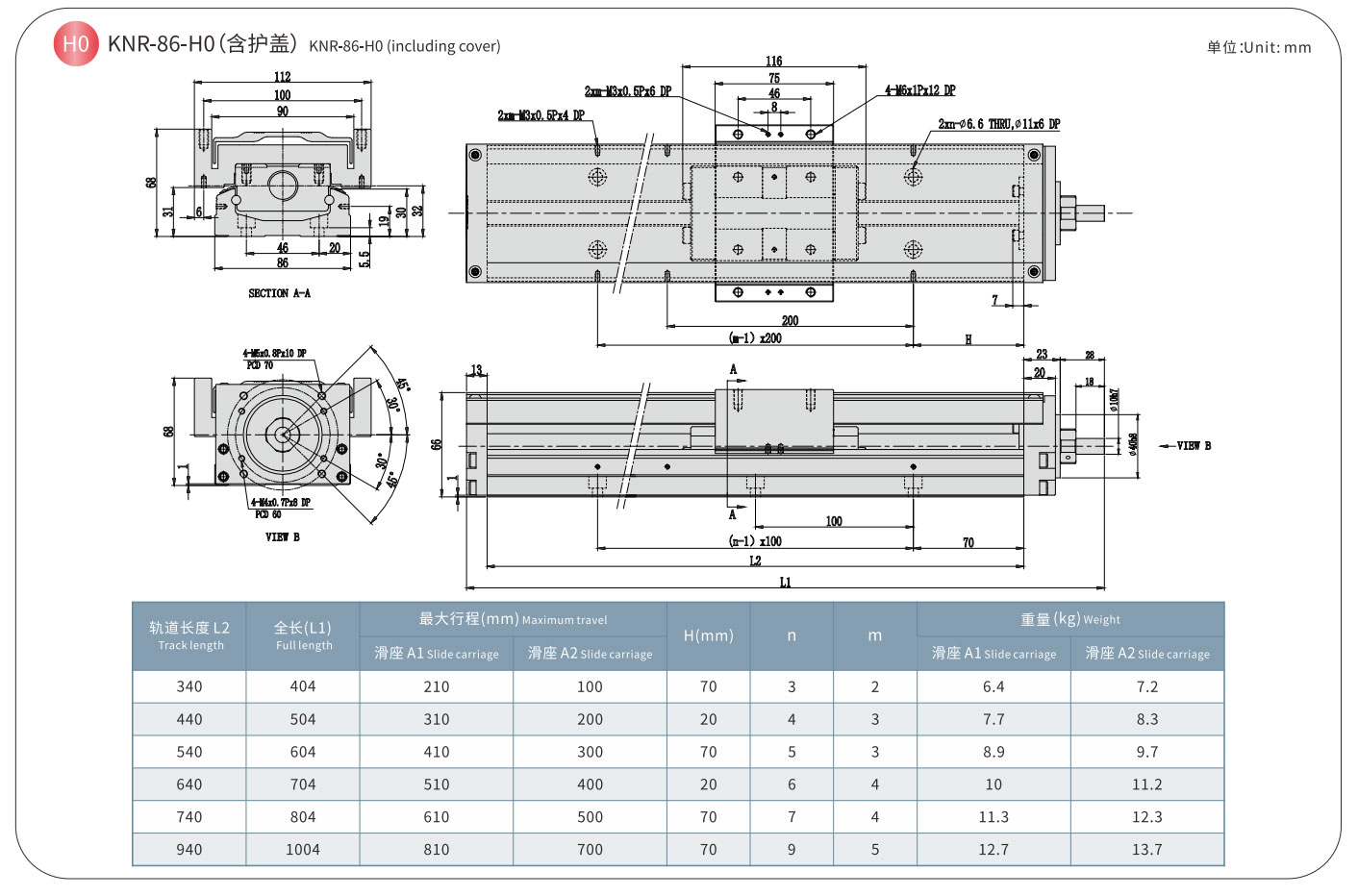

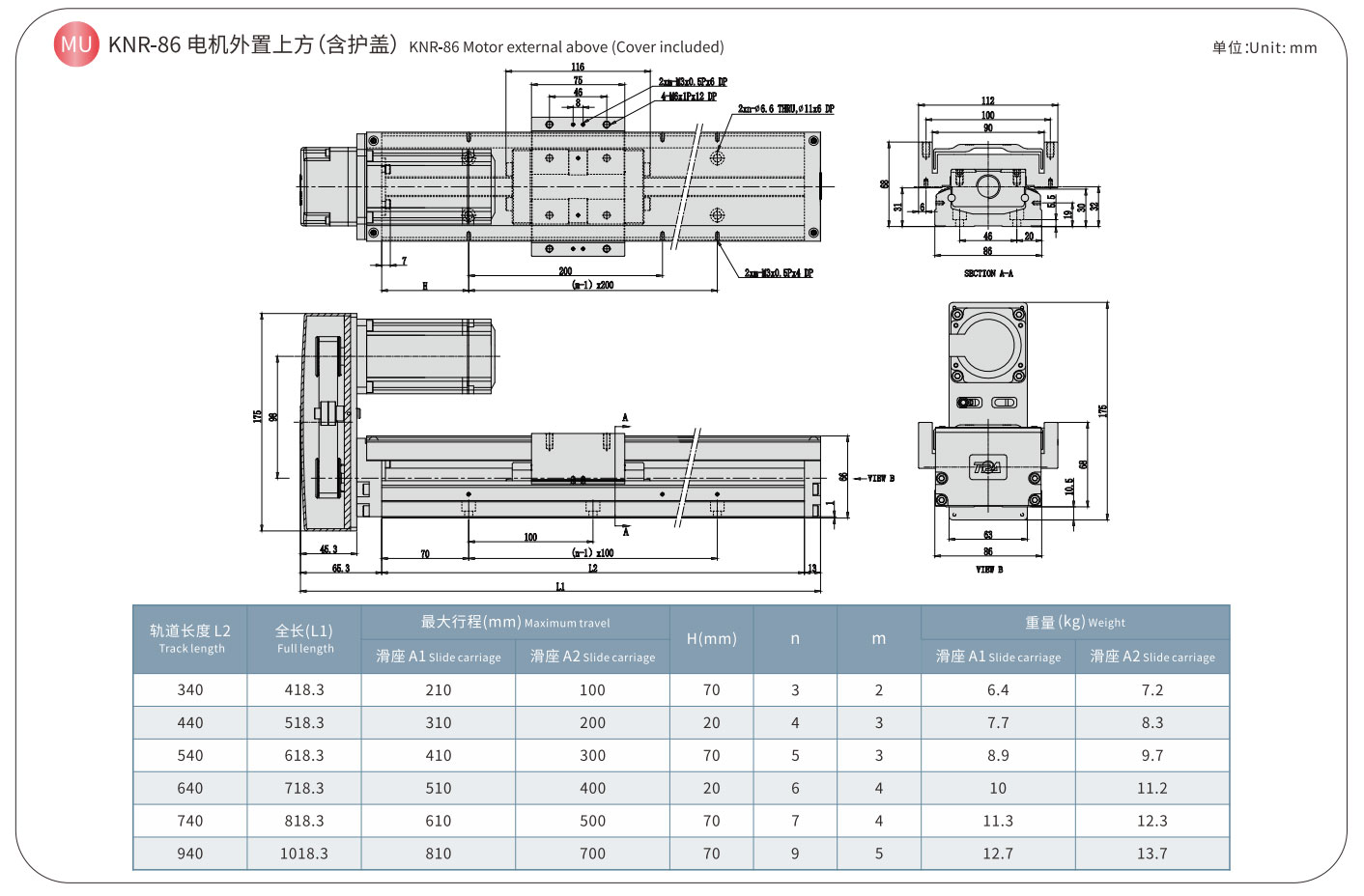

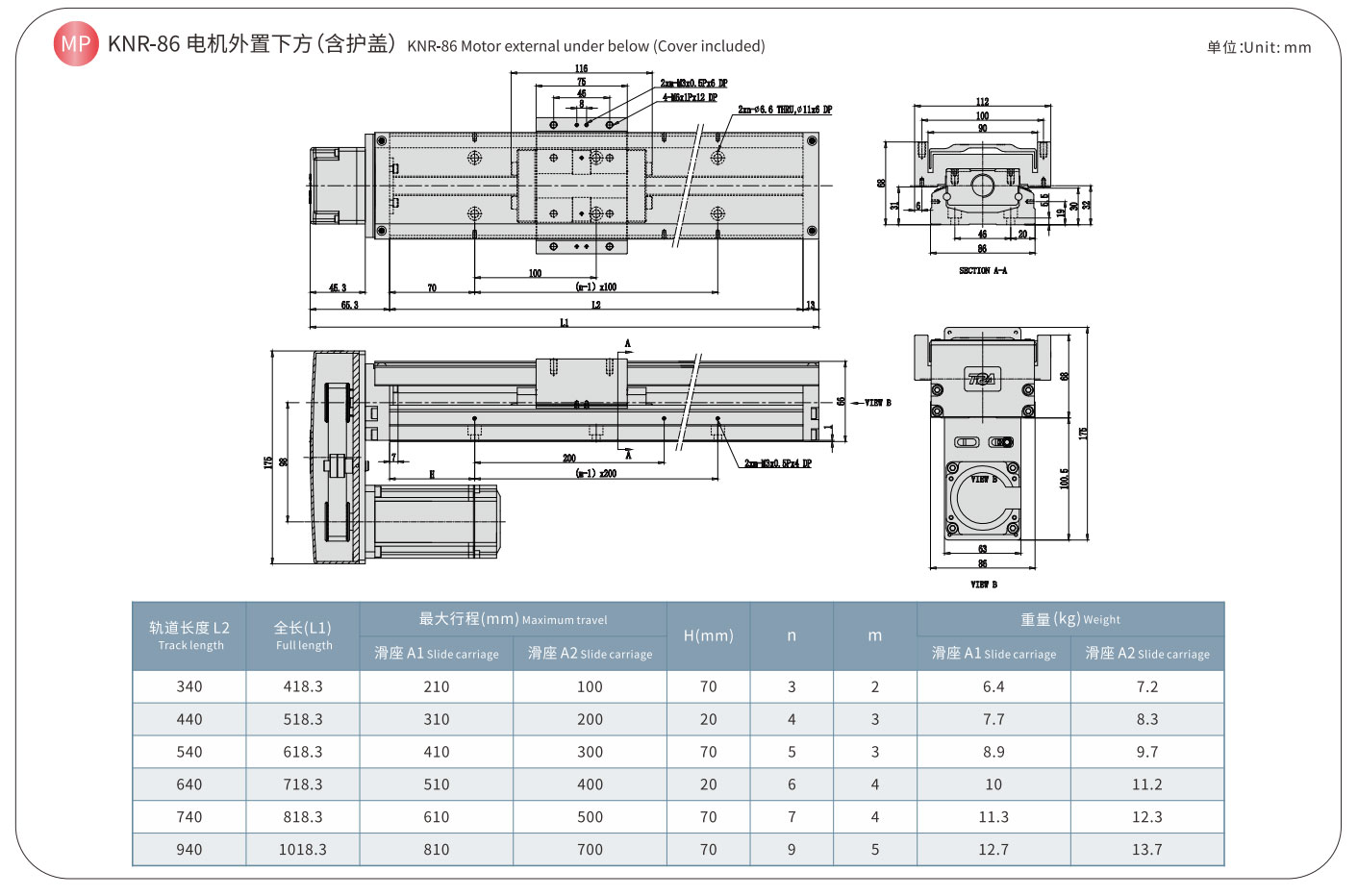

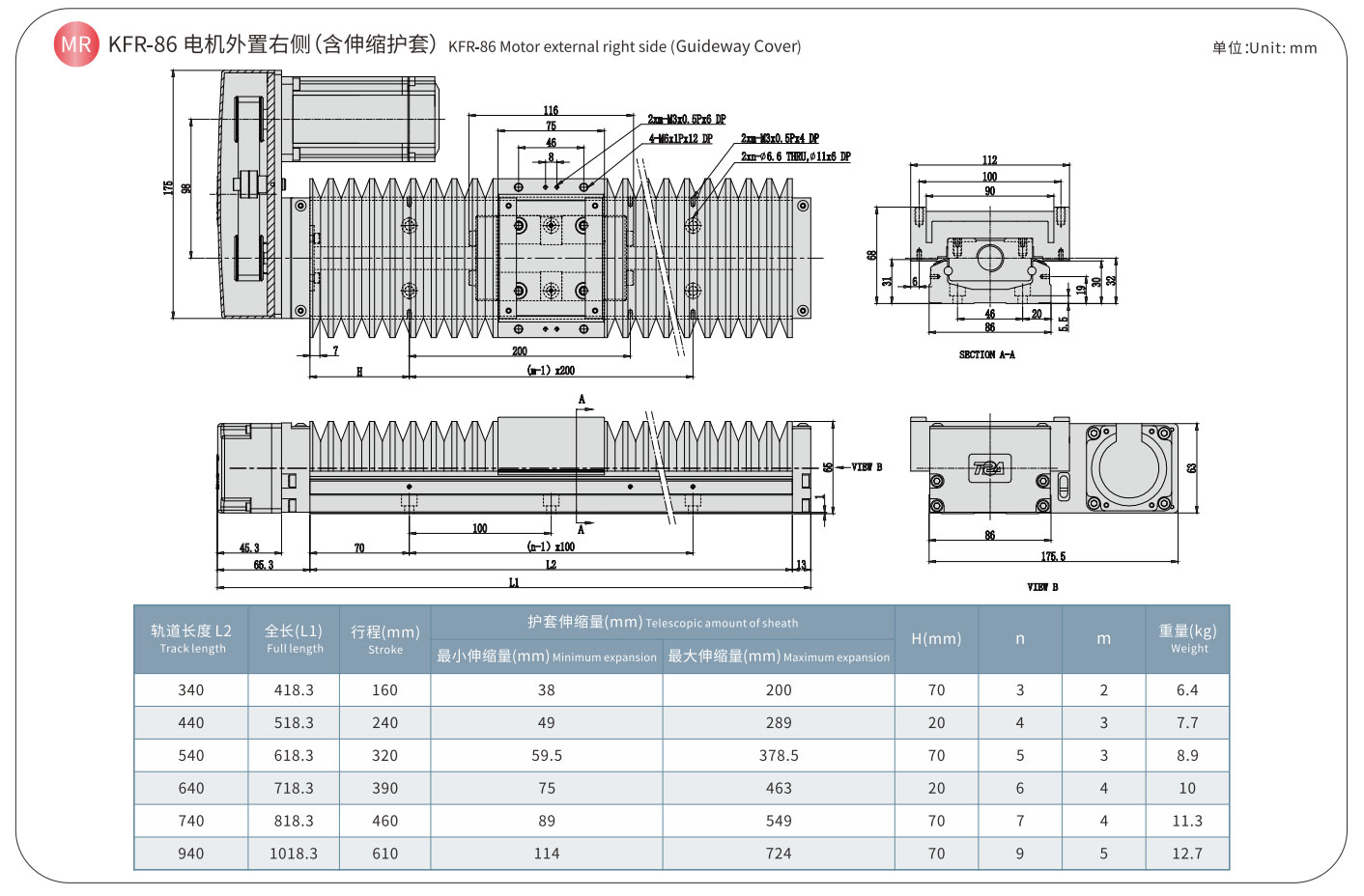

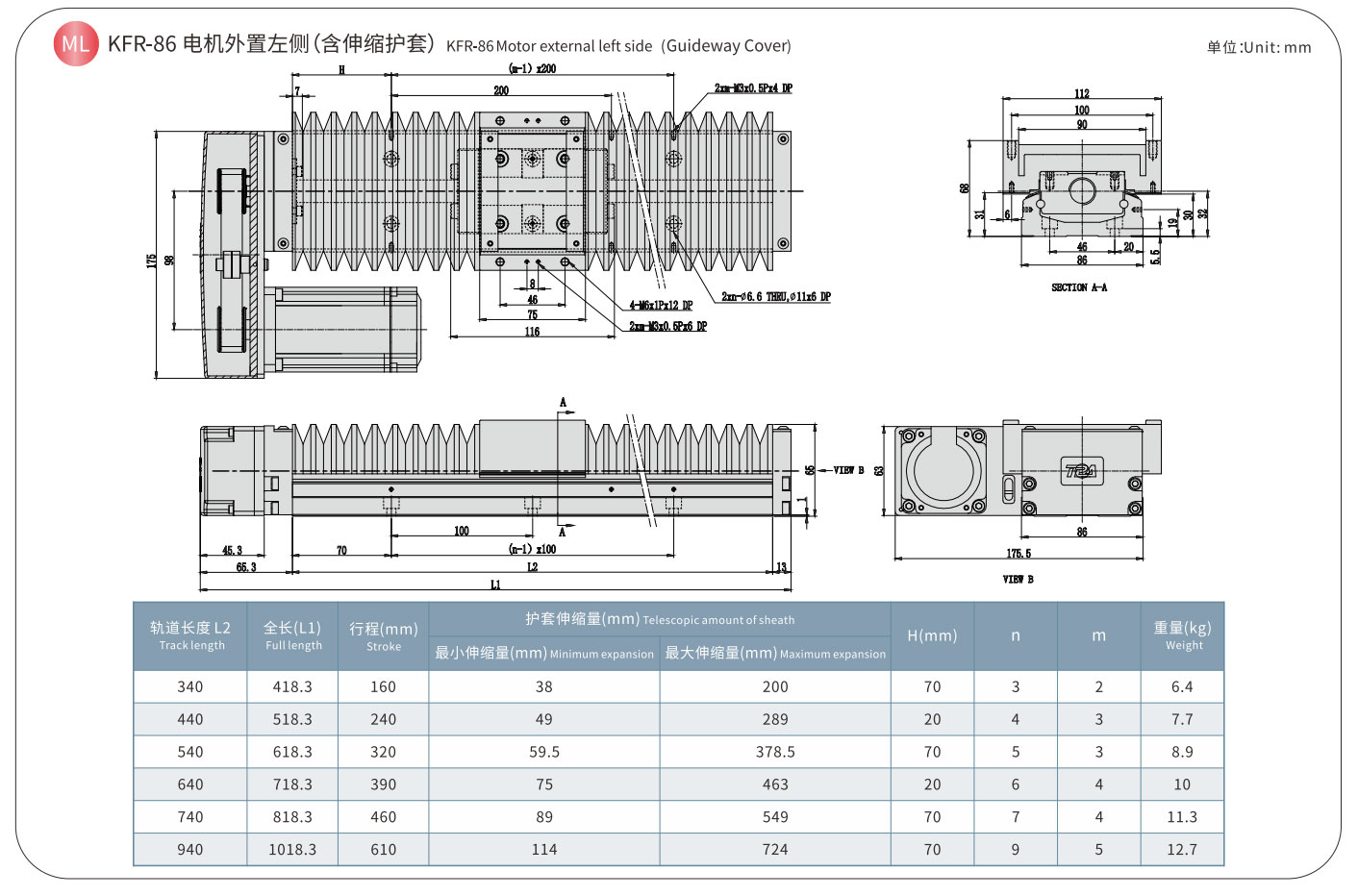

The KK Series single axis robot, developed by TPA ROBOT, uses partially hardened U-shaped steel base track to significantly increase the robot’s strength and load capacity. Due to the different environments, we have three type of linear robot series, KSR, KNR and KFR, depending on the type of cover used.

For the return system between the track and the slider, the contact surface between the ball and the ball groove adopts a 2-row Goethe tooth design with a contact angle of 45 degrees, which can make axis robot arm bear equal load capacity in four directions.

At the same time, the high-precision ball screw is used as the transmission structure, and the U-shaped track cooperates with the optimized design, so that KK axis robot has unparalleled precision, and its repeated positioning accuracy can reach ±0.003mm.

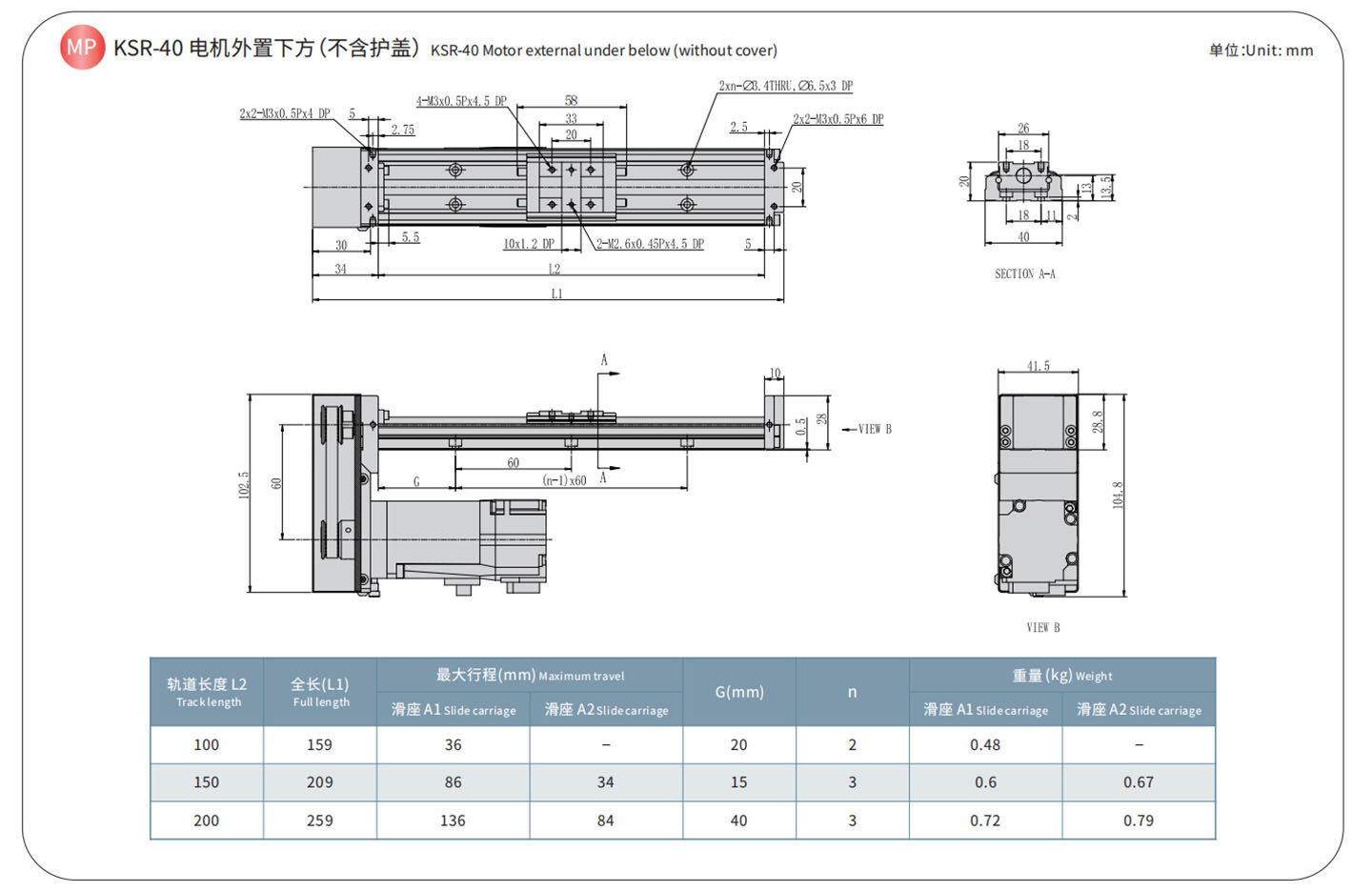

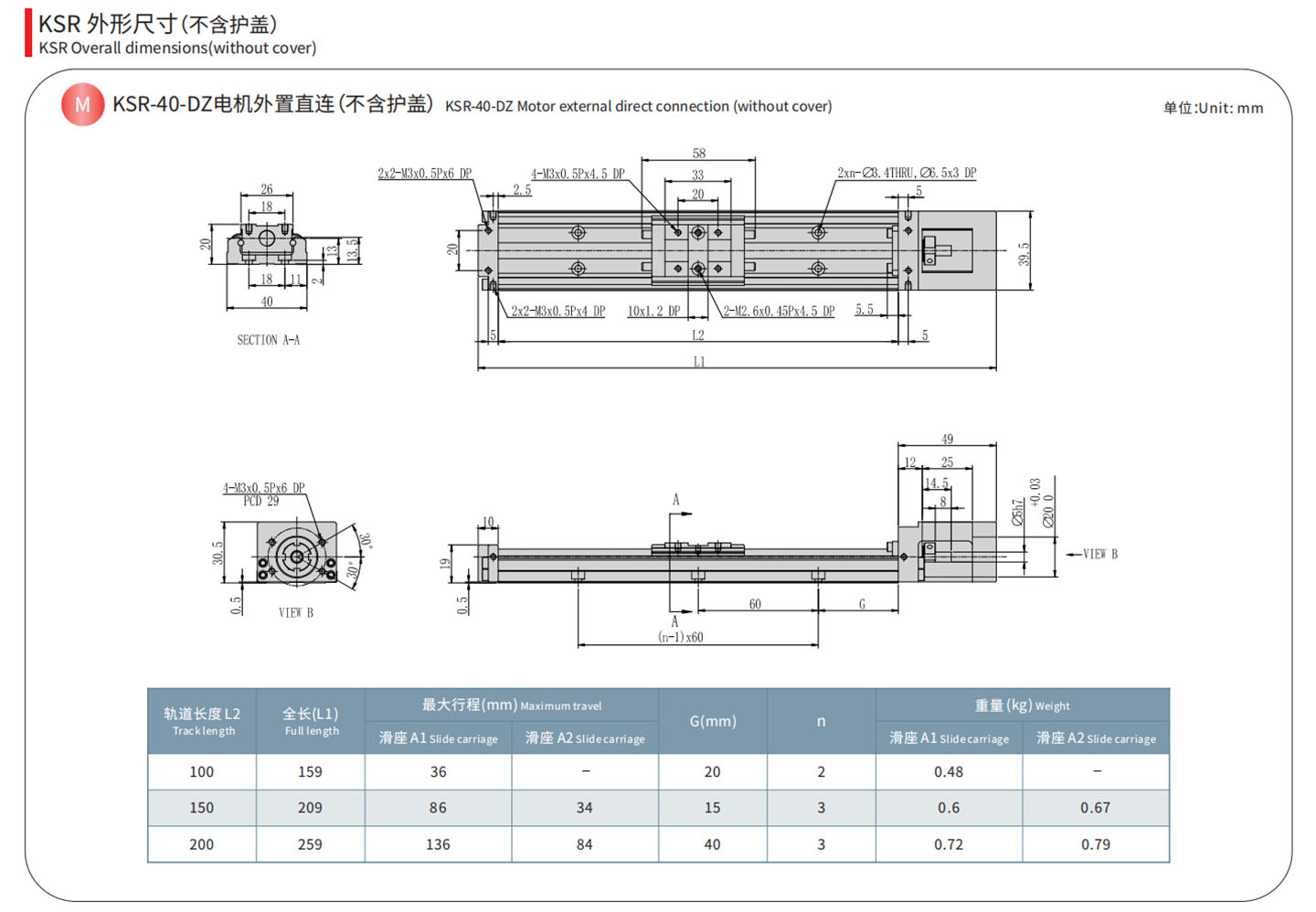

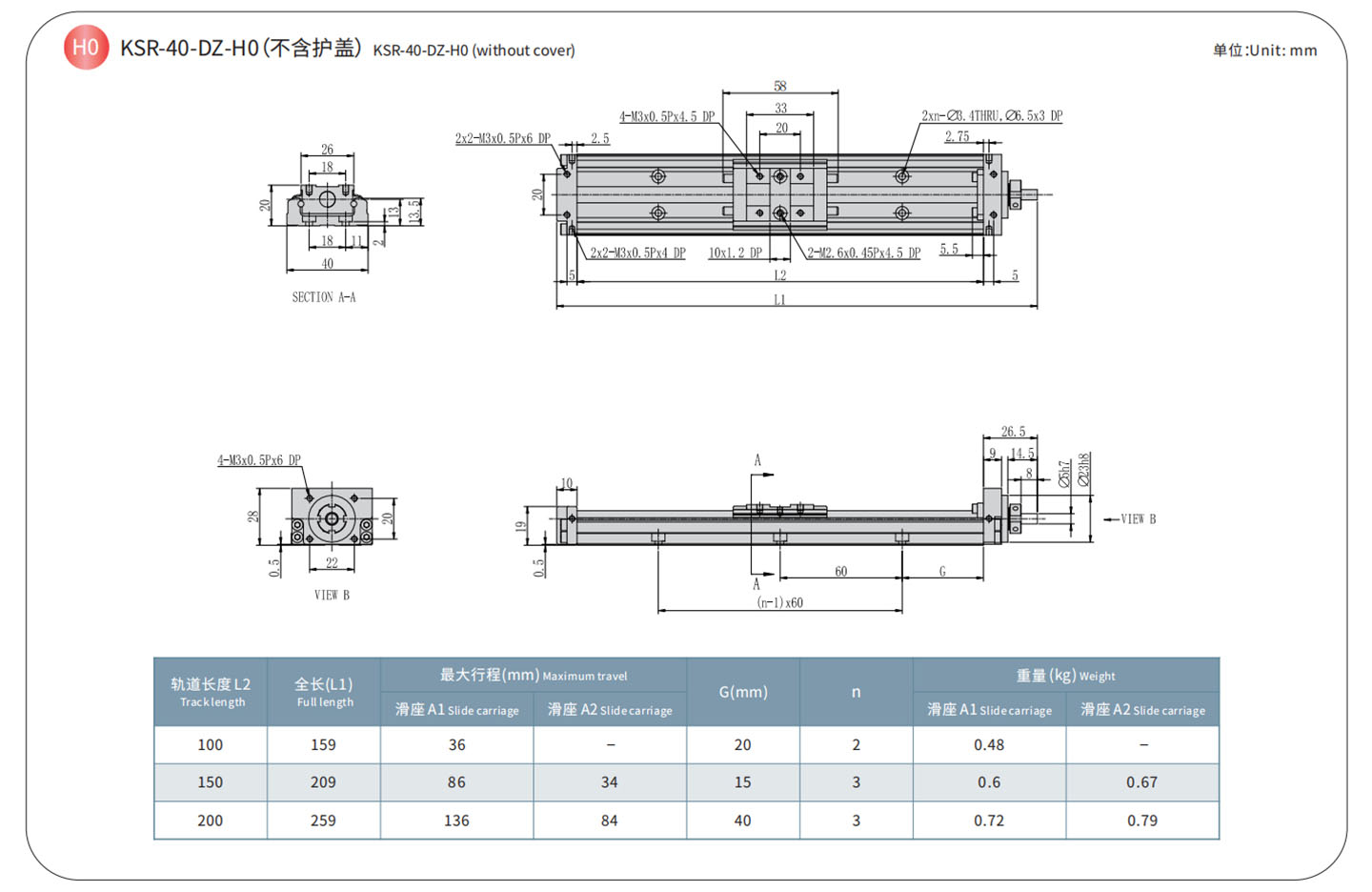

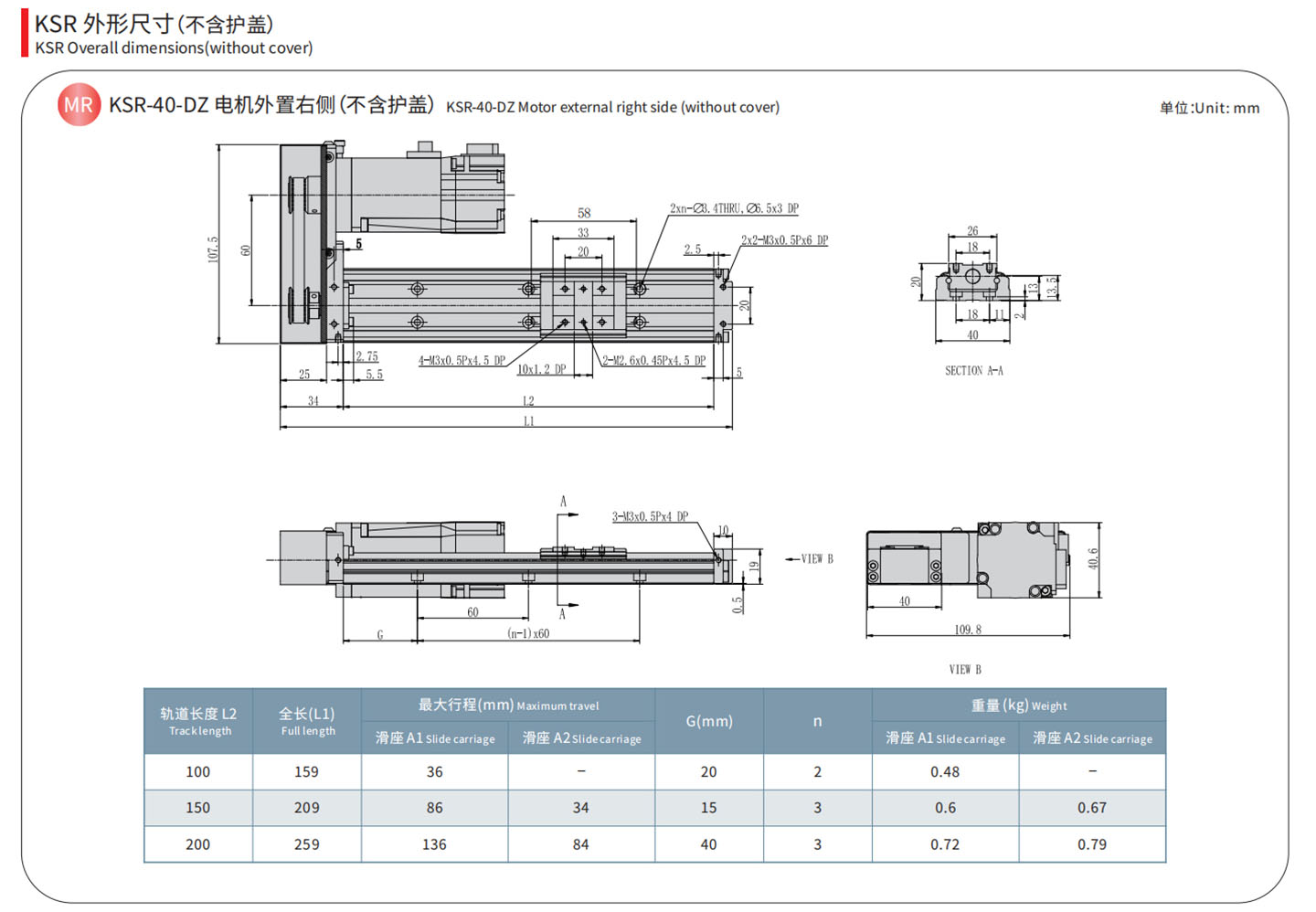

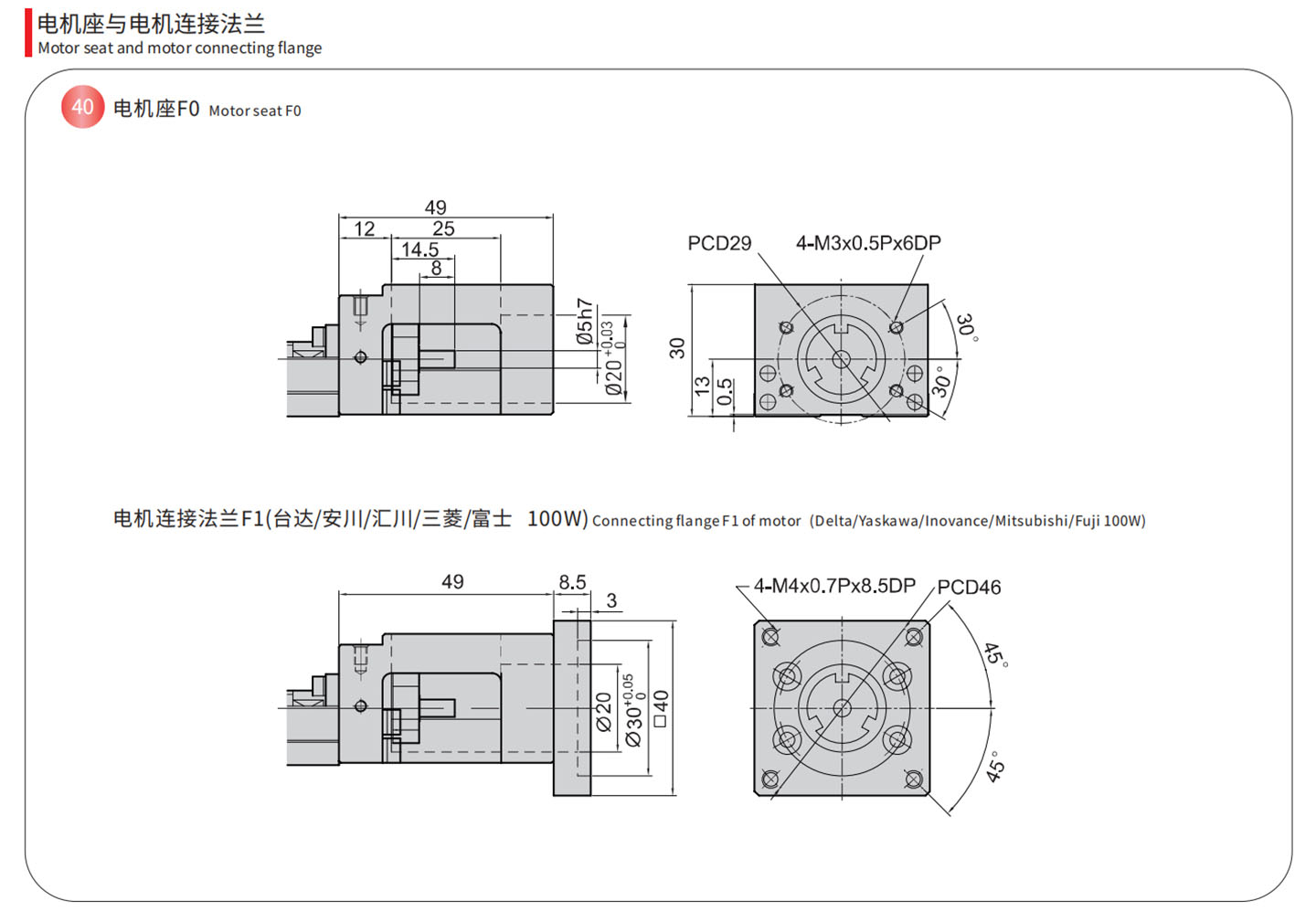

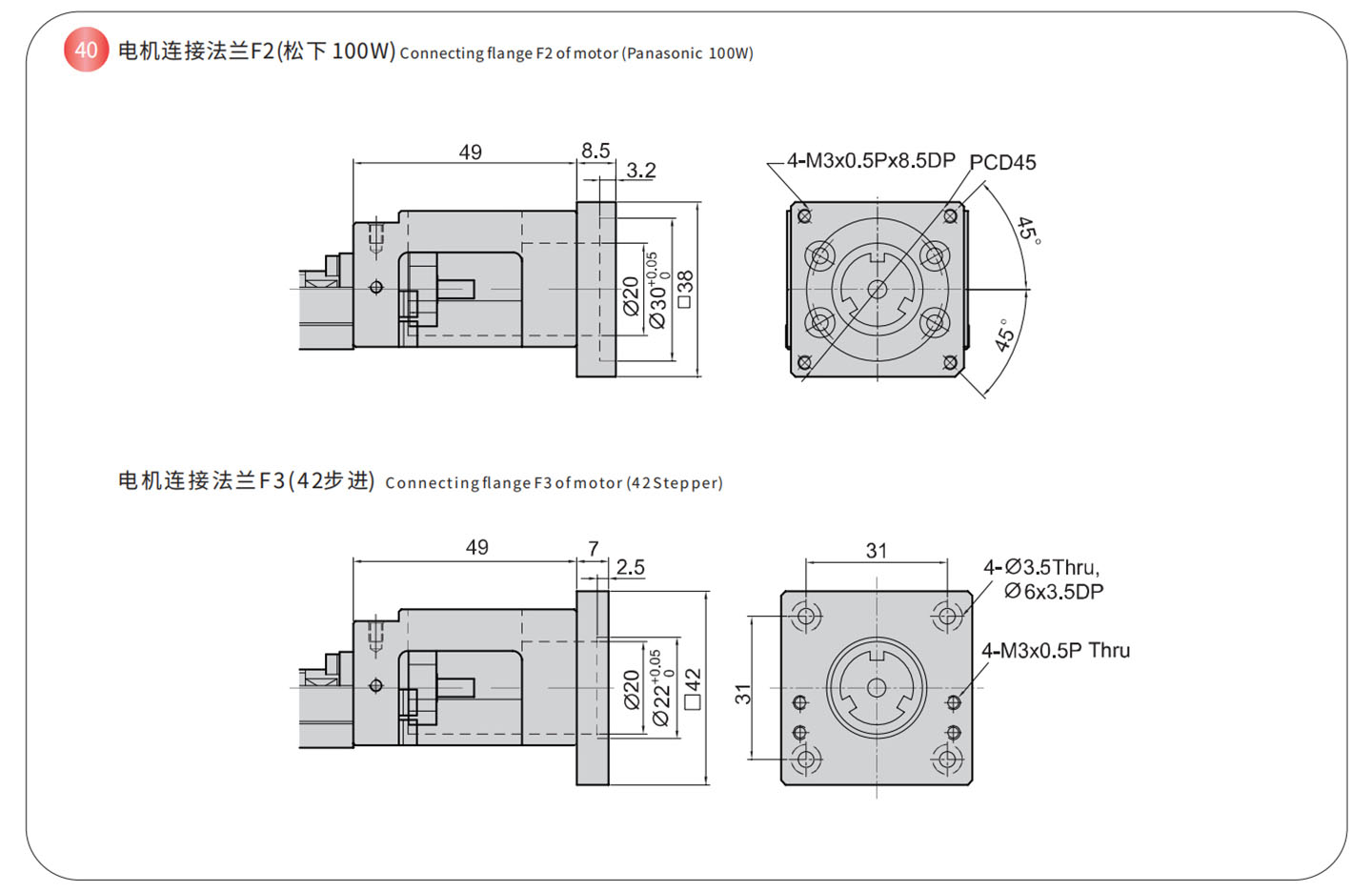

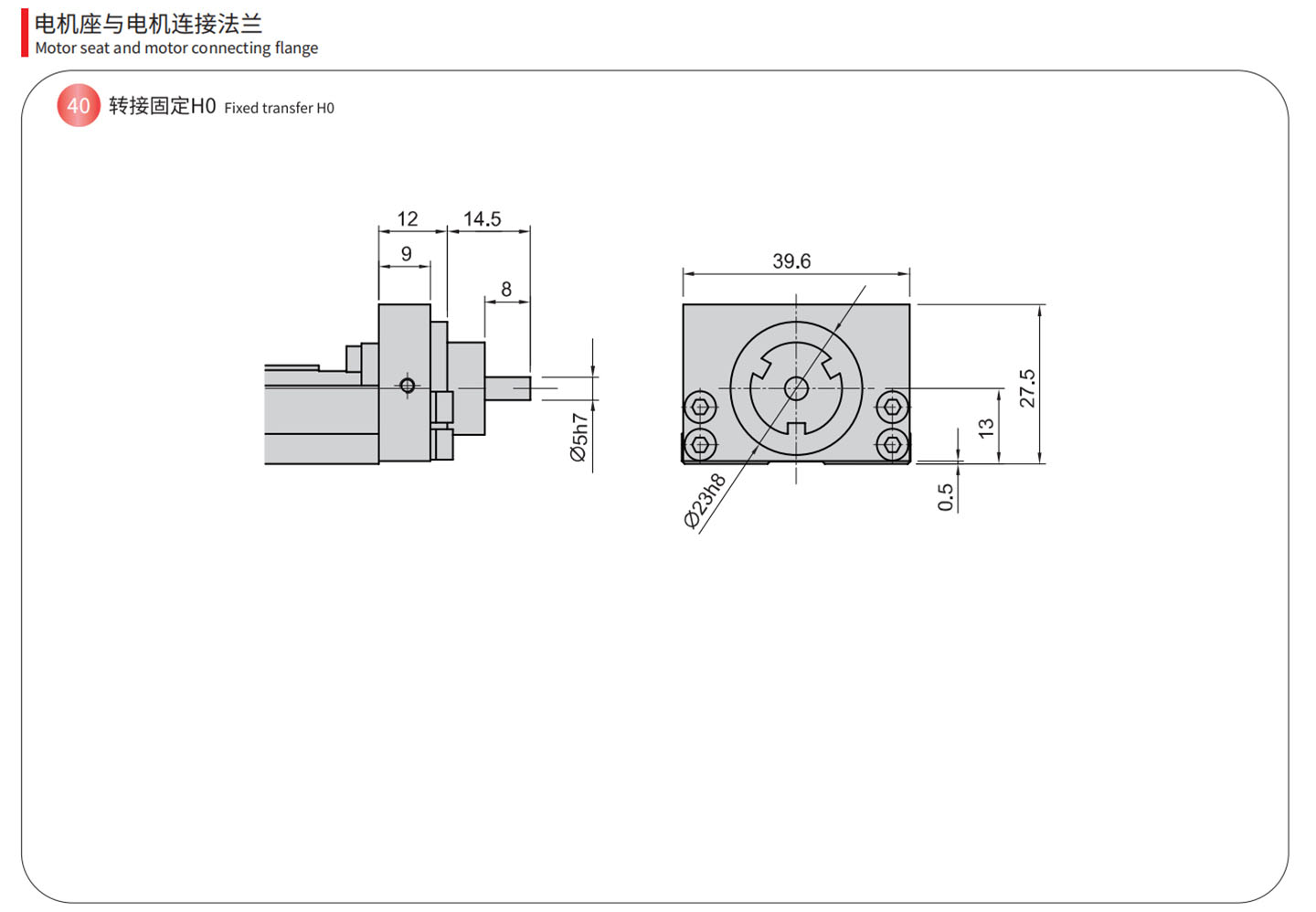

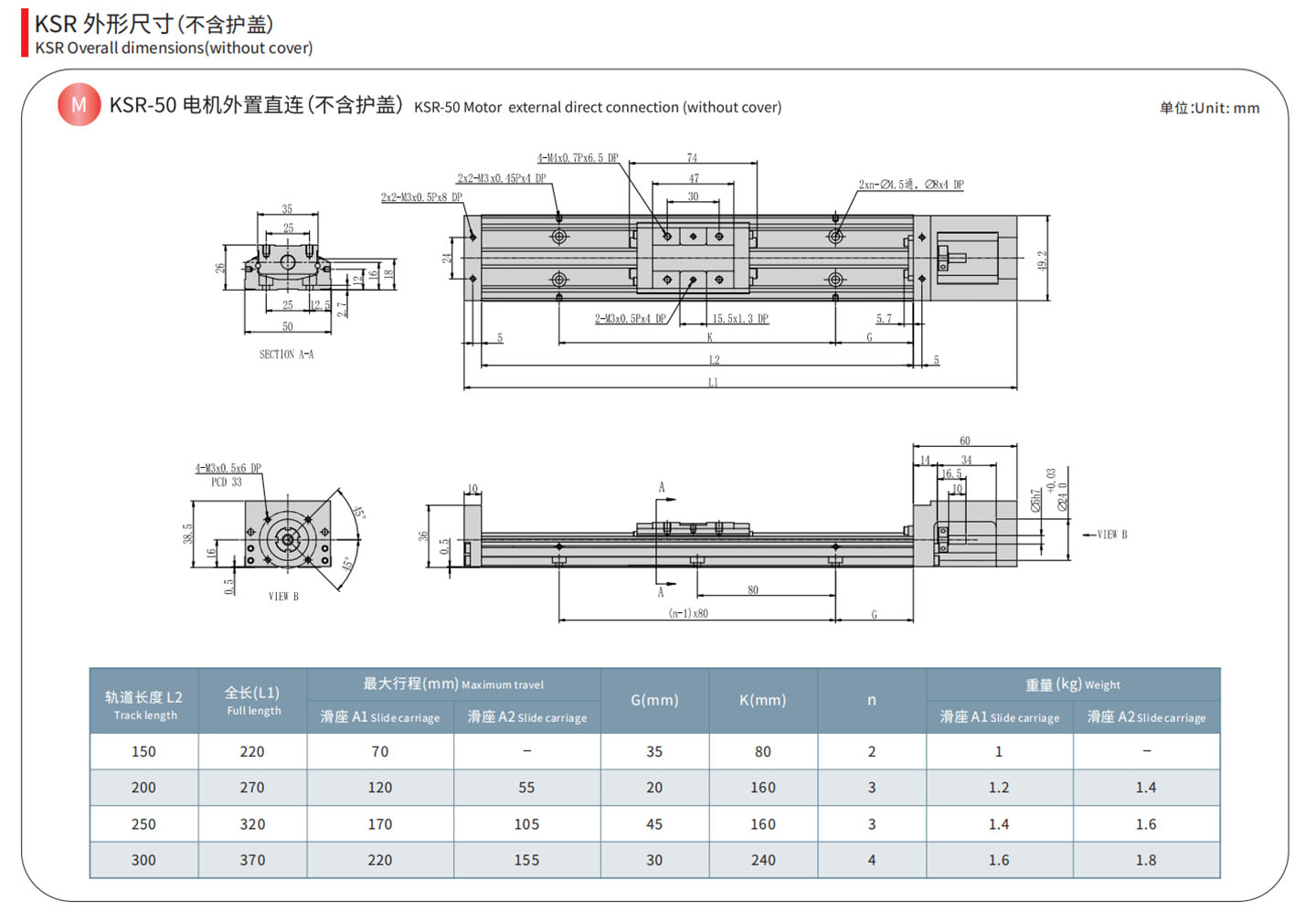

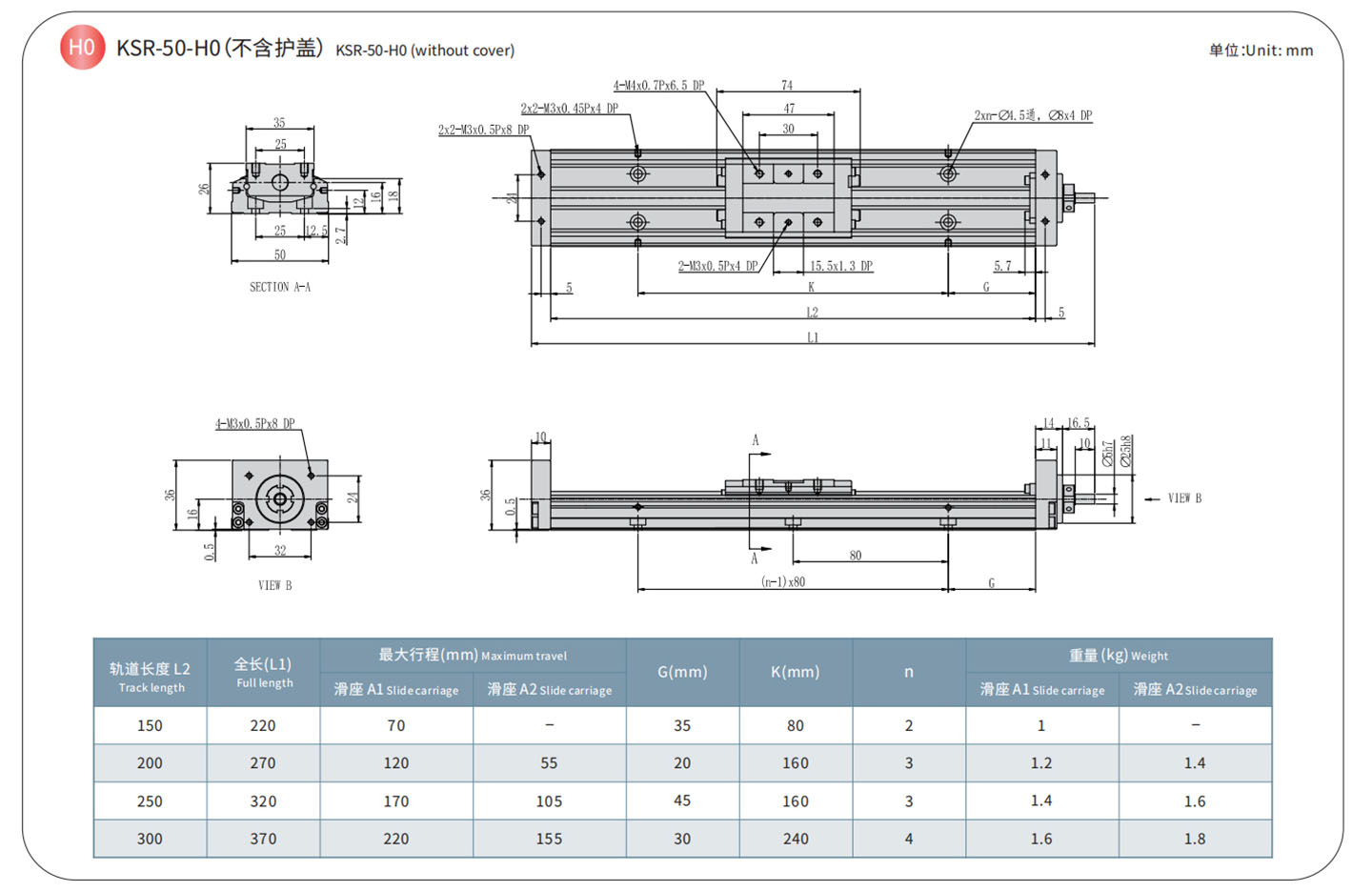

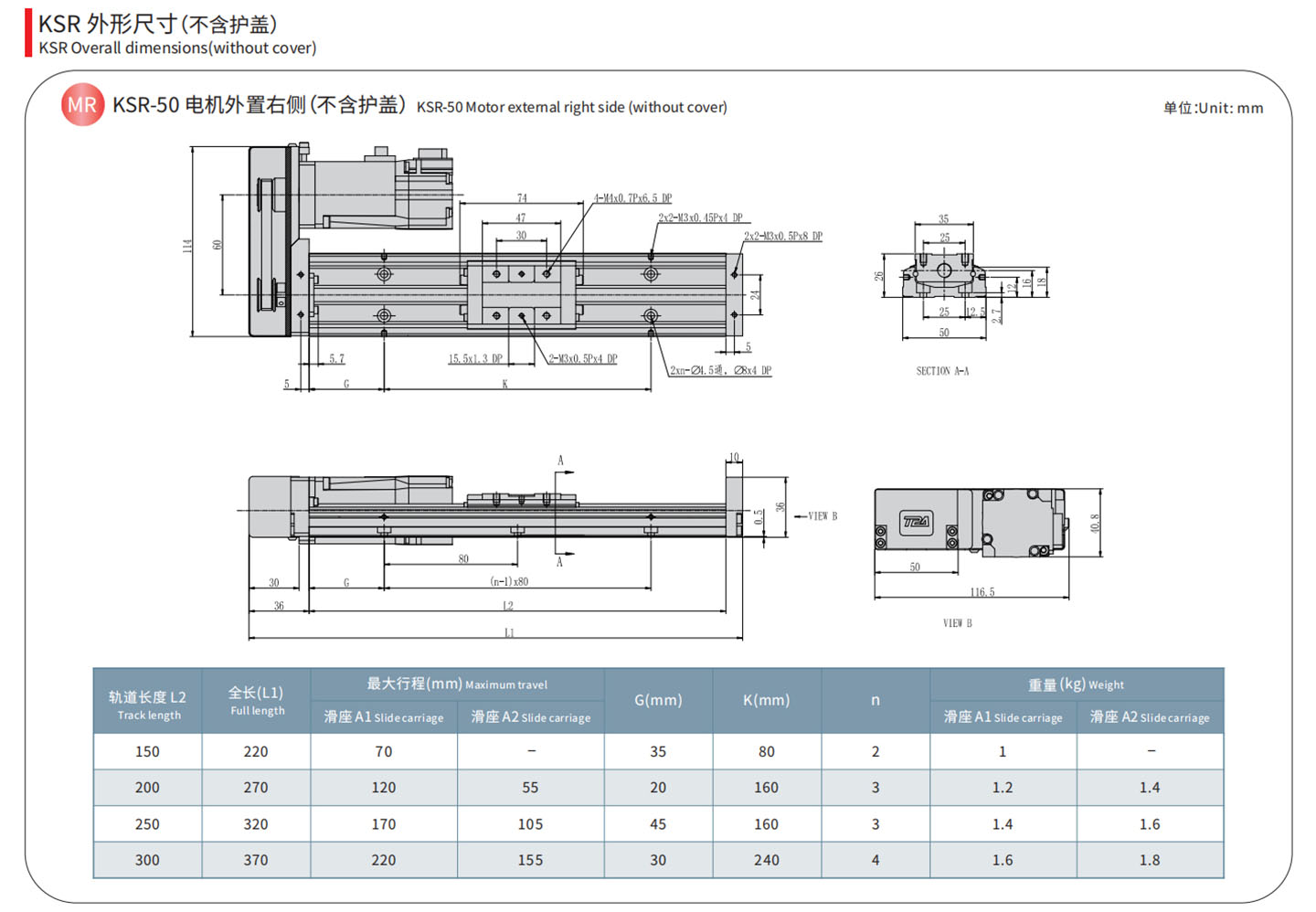

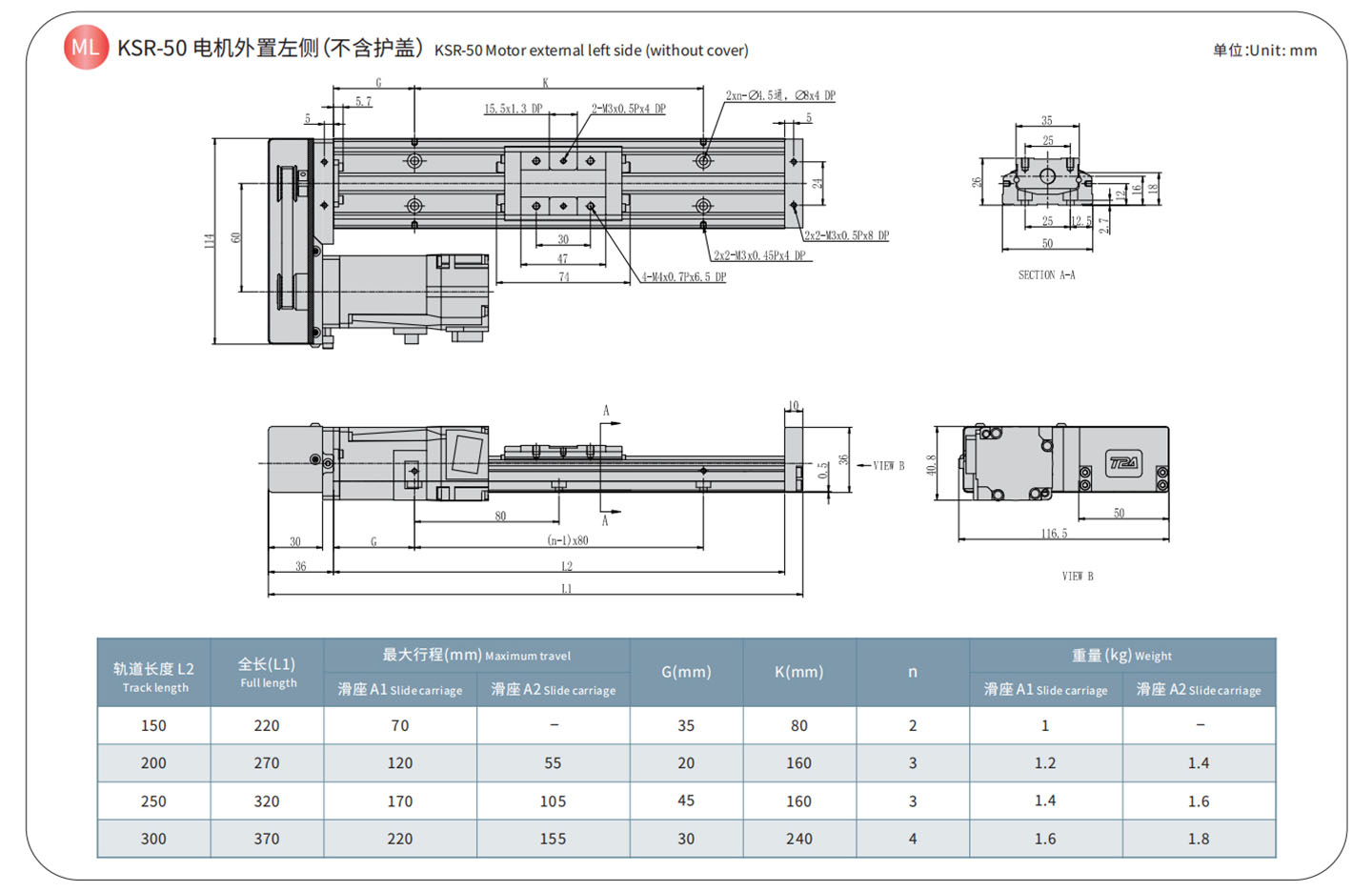

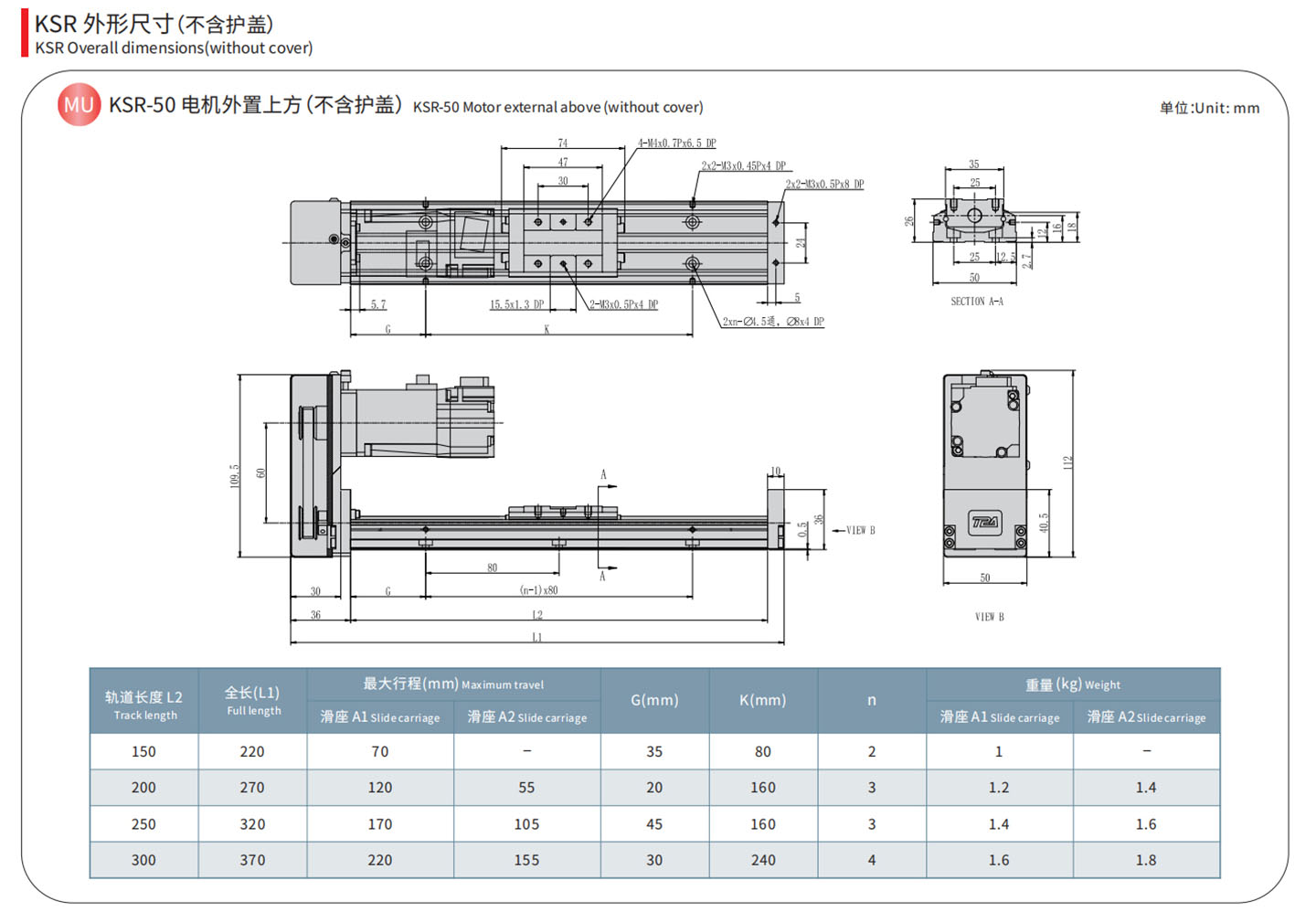

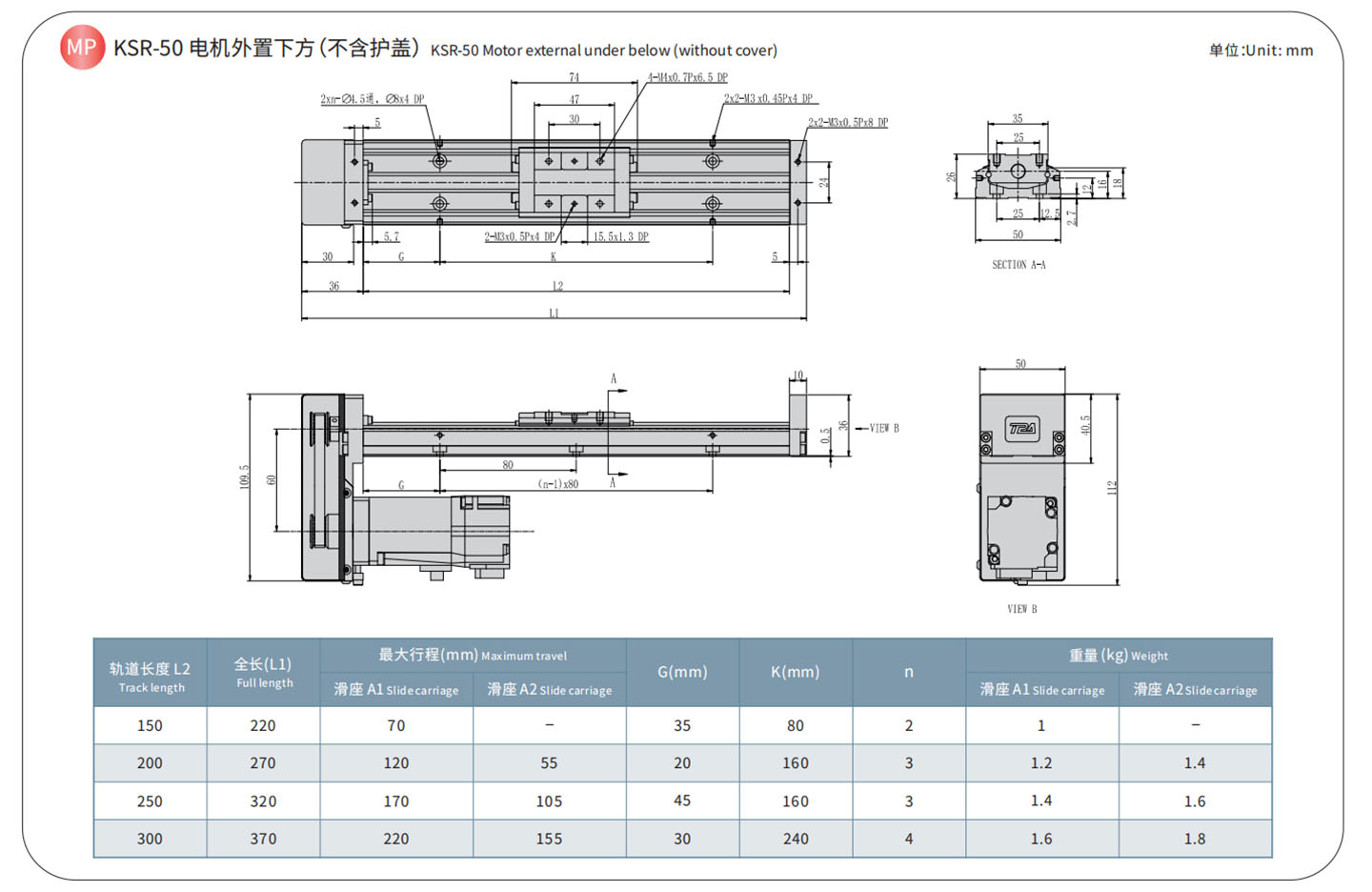

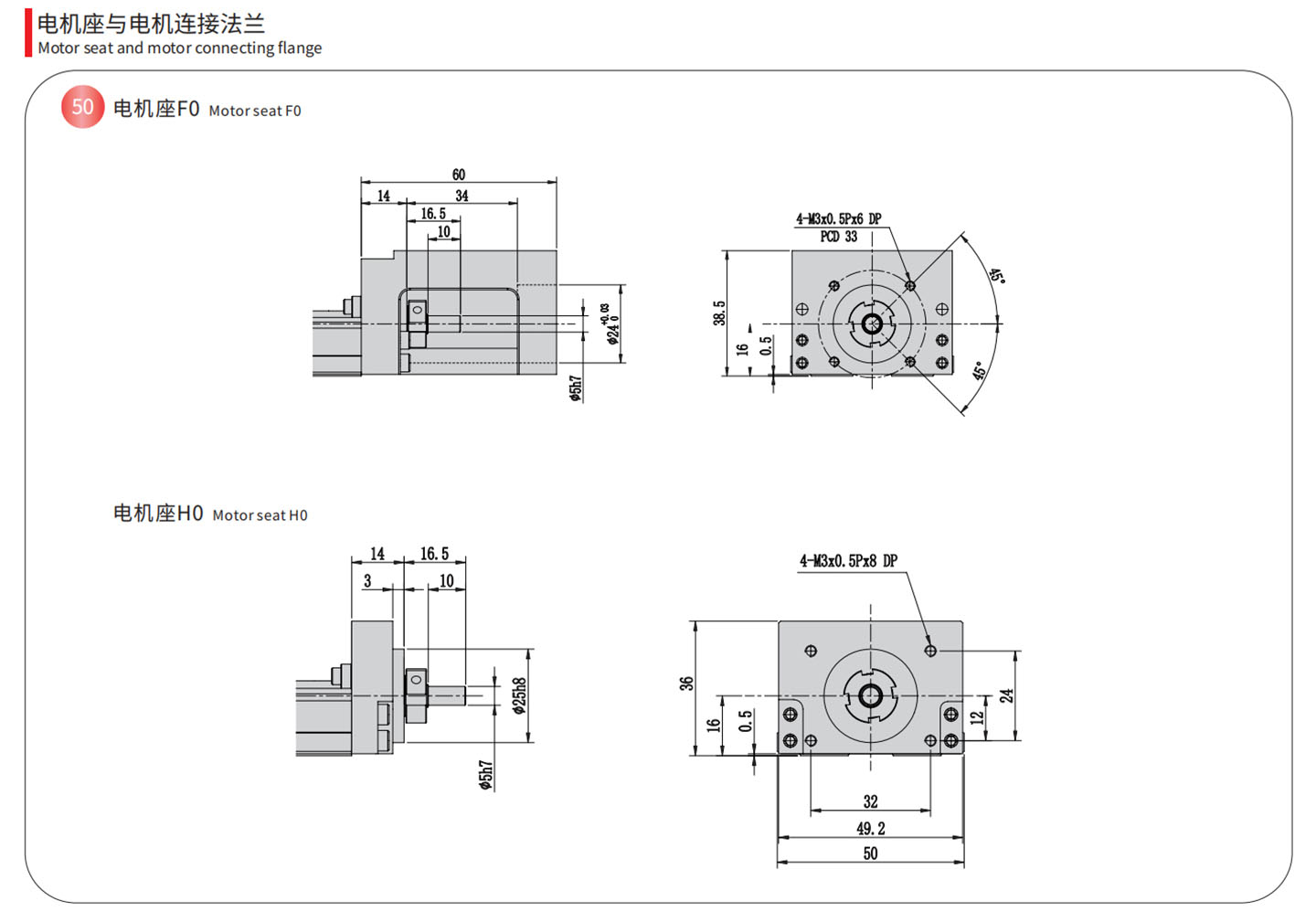

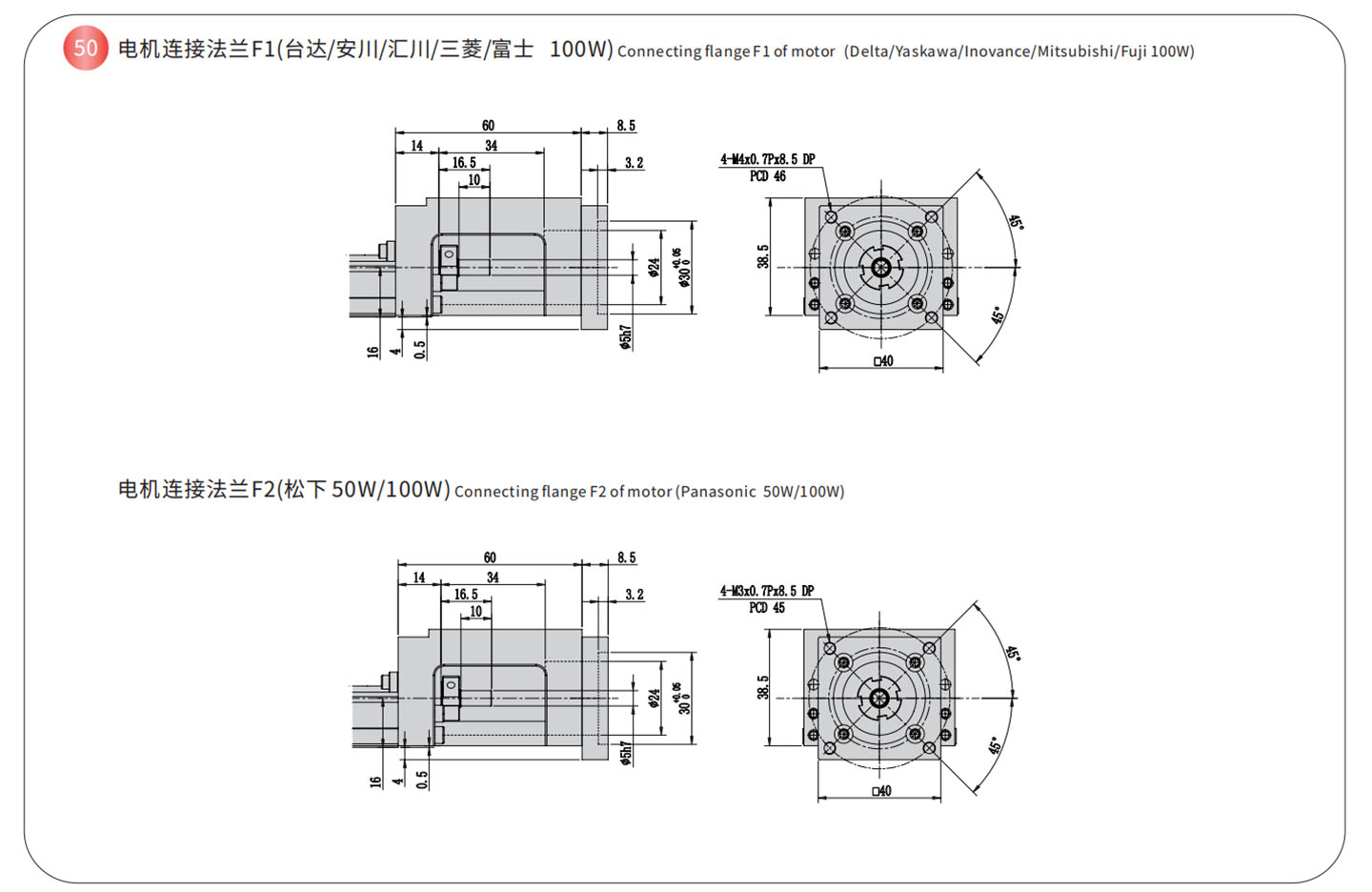

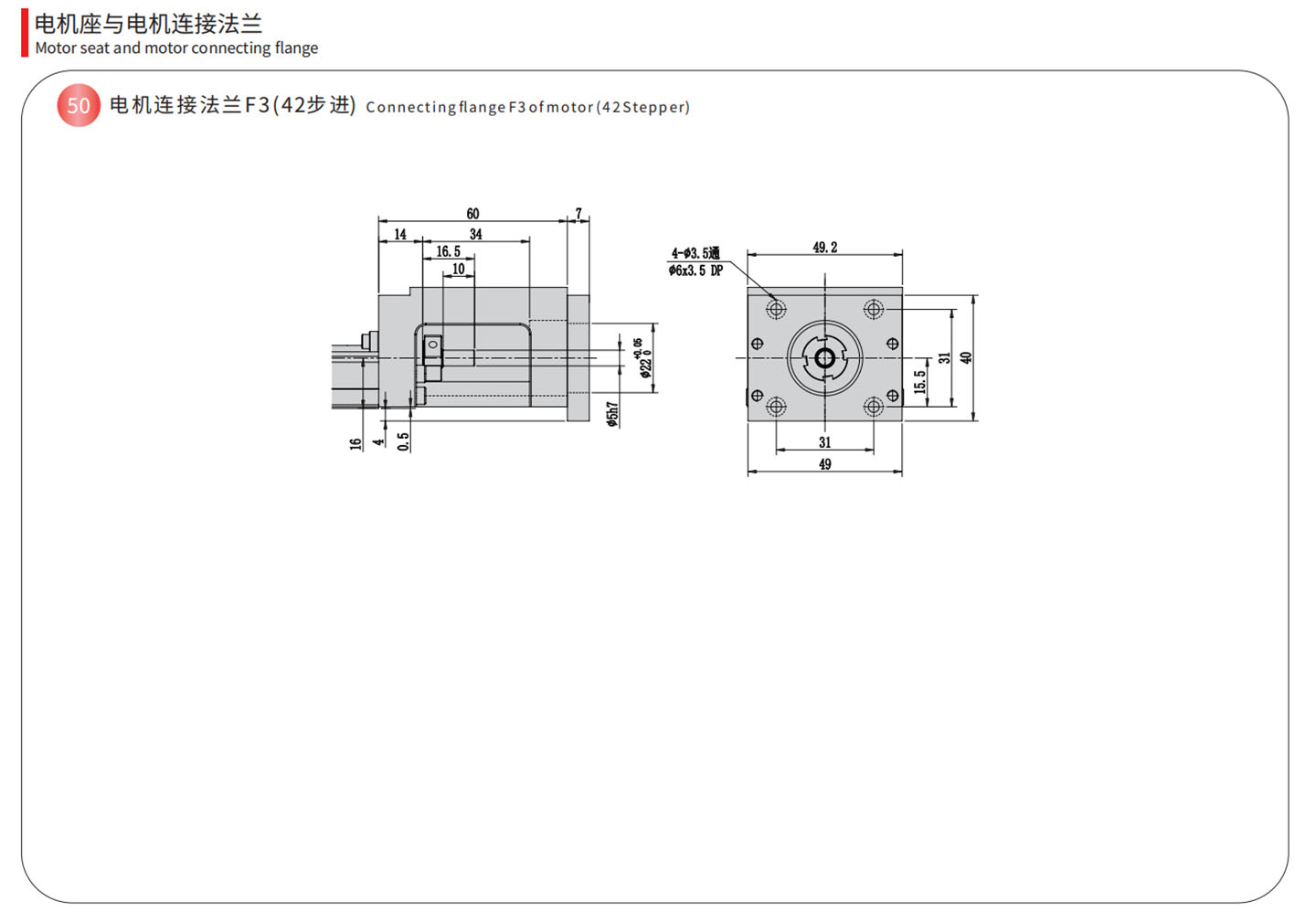

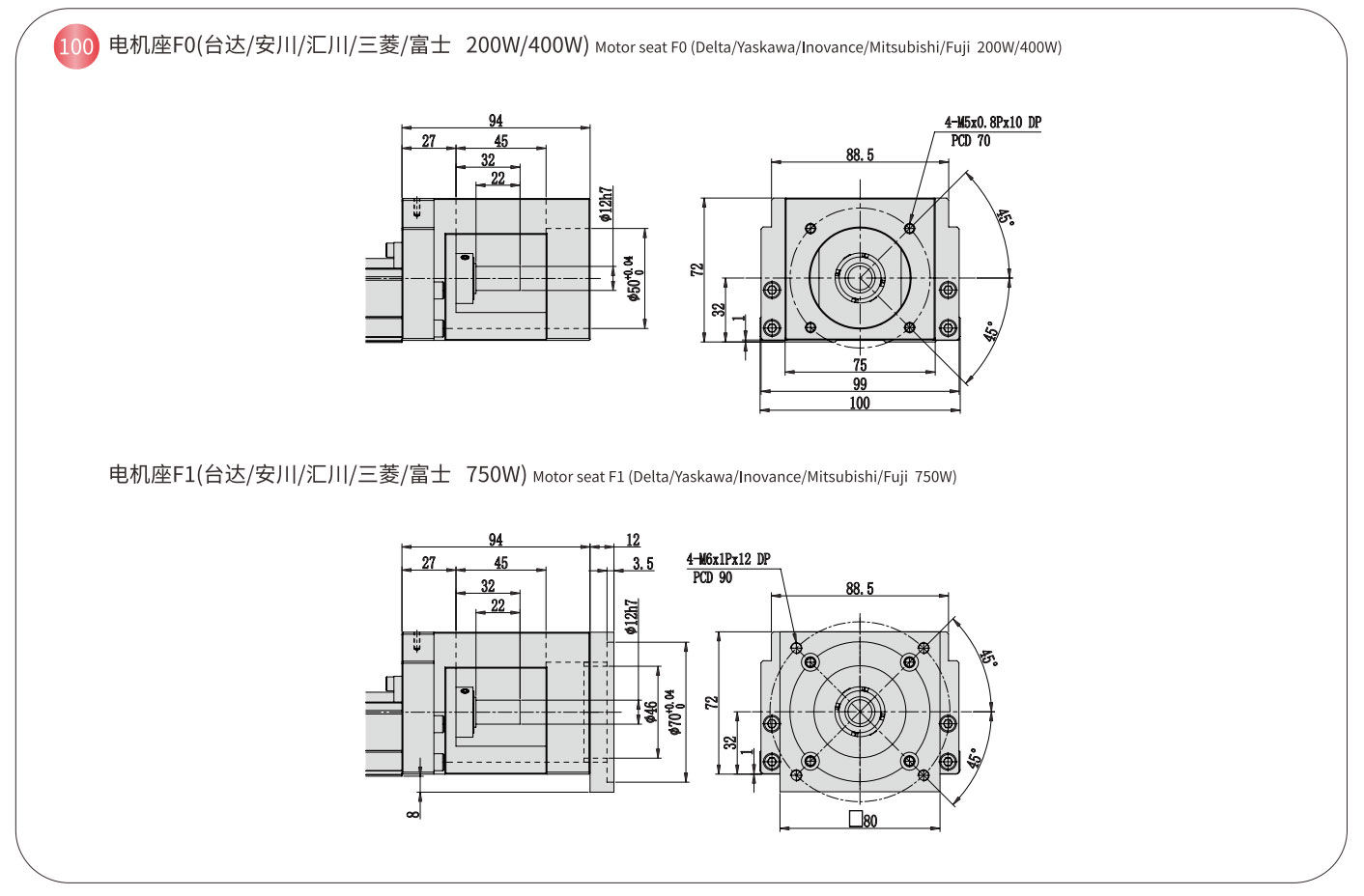

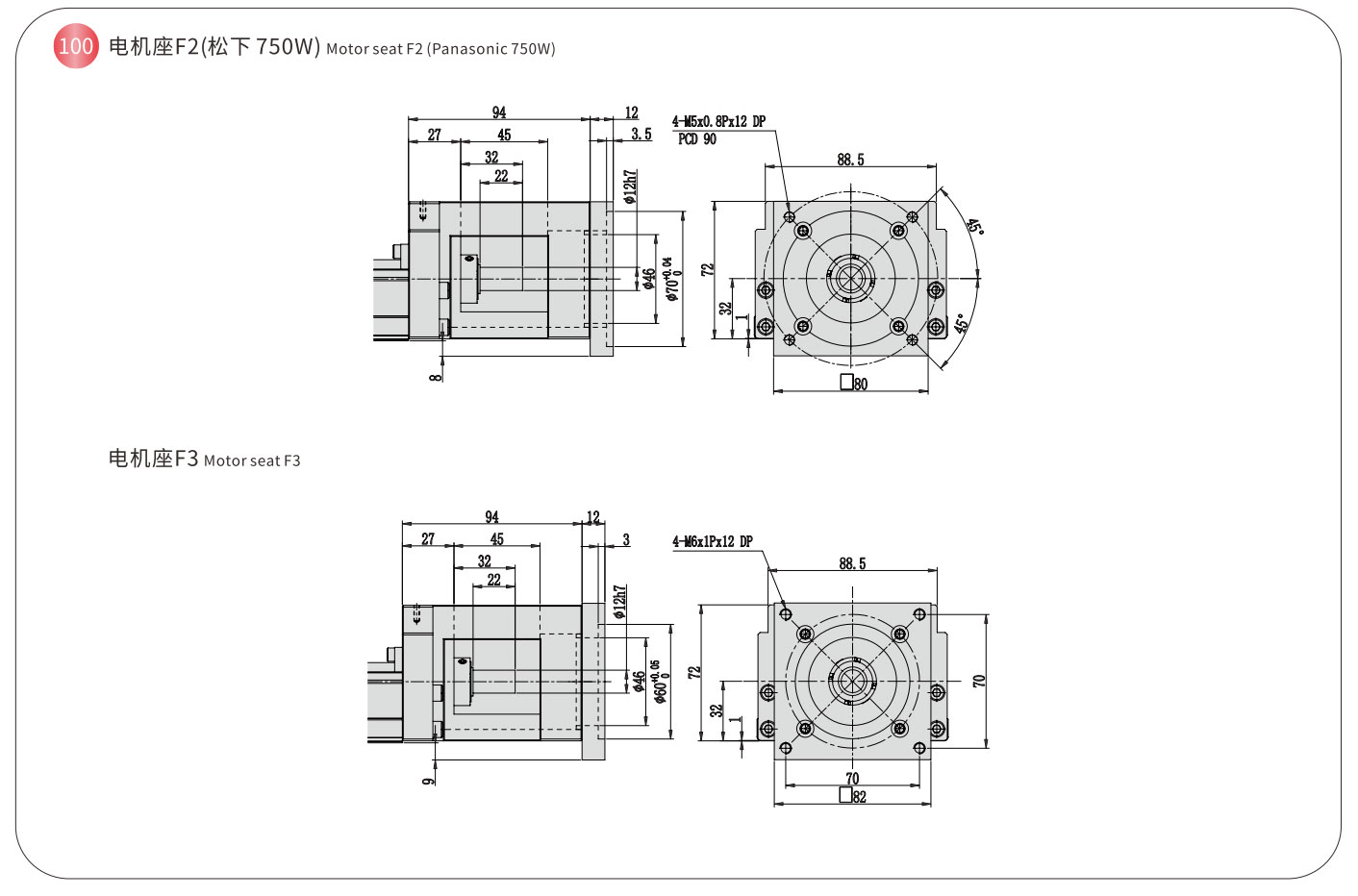

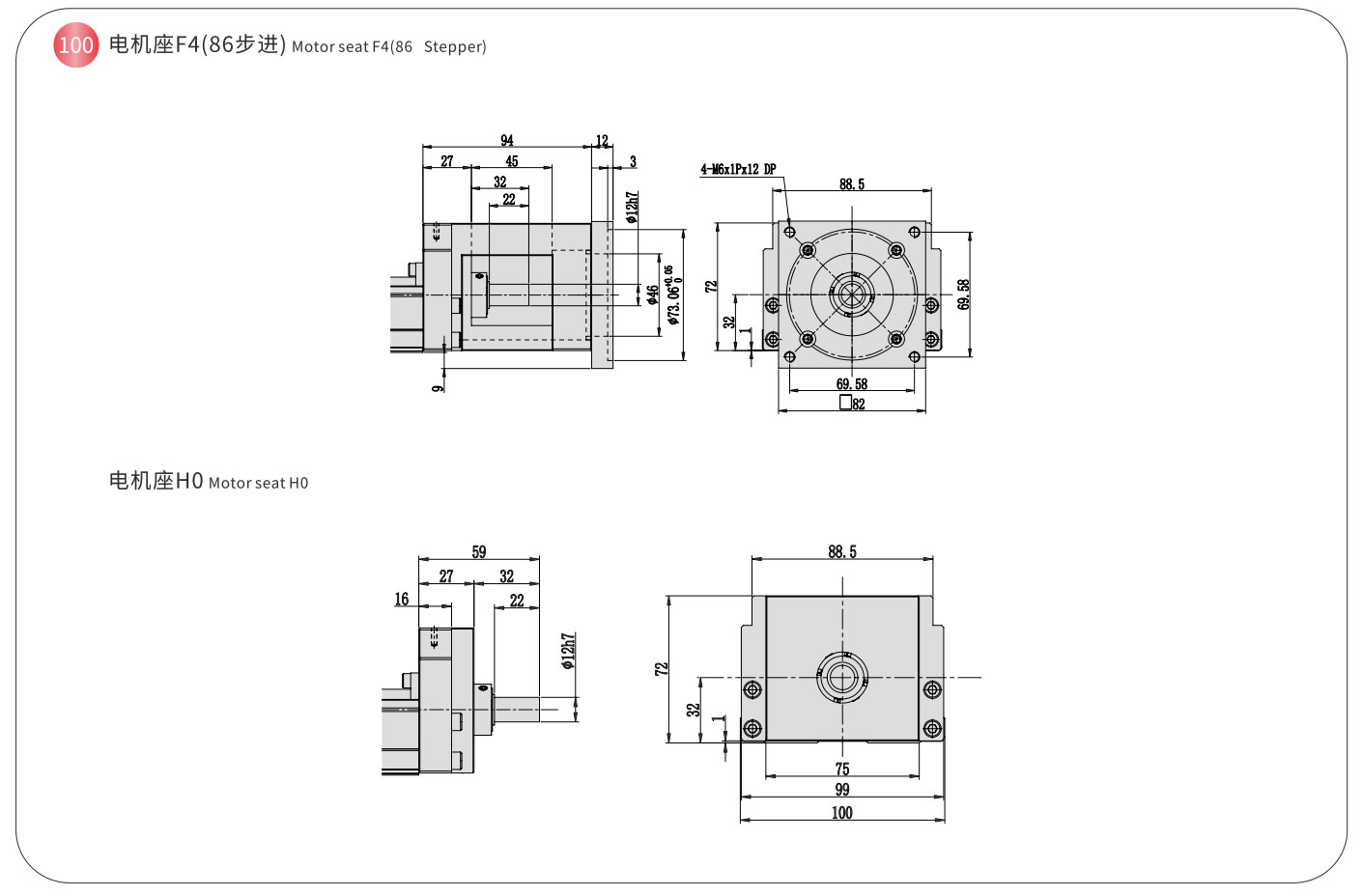

Under the same load conditions, our single axis robot KK Series is smaller in size, we provide standard threaded holes on the steel base and slider, and our motor adapter plate can provide up to 8 motor installation methods, which means it can be easily assembled any cartesian robotic system. Therefore, KK series single axis robots are widely used in silicon wafer handling, automatic dispensing, FPD industry, medical automation industry, precision measuring instruments, sliding table, linear slide table coordination industry.

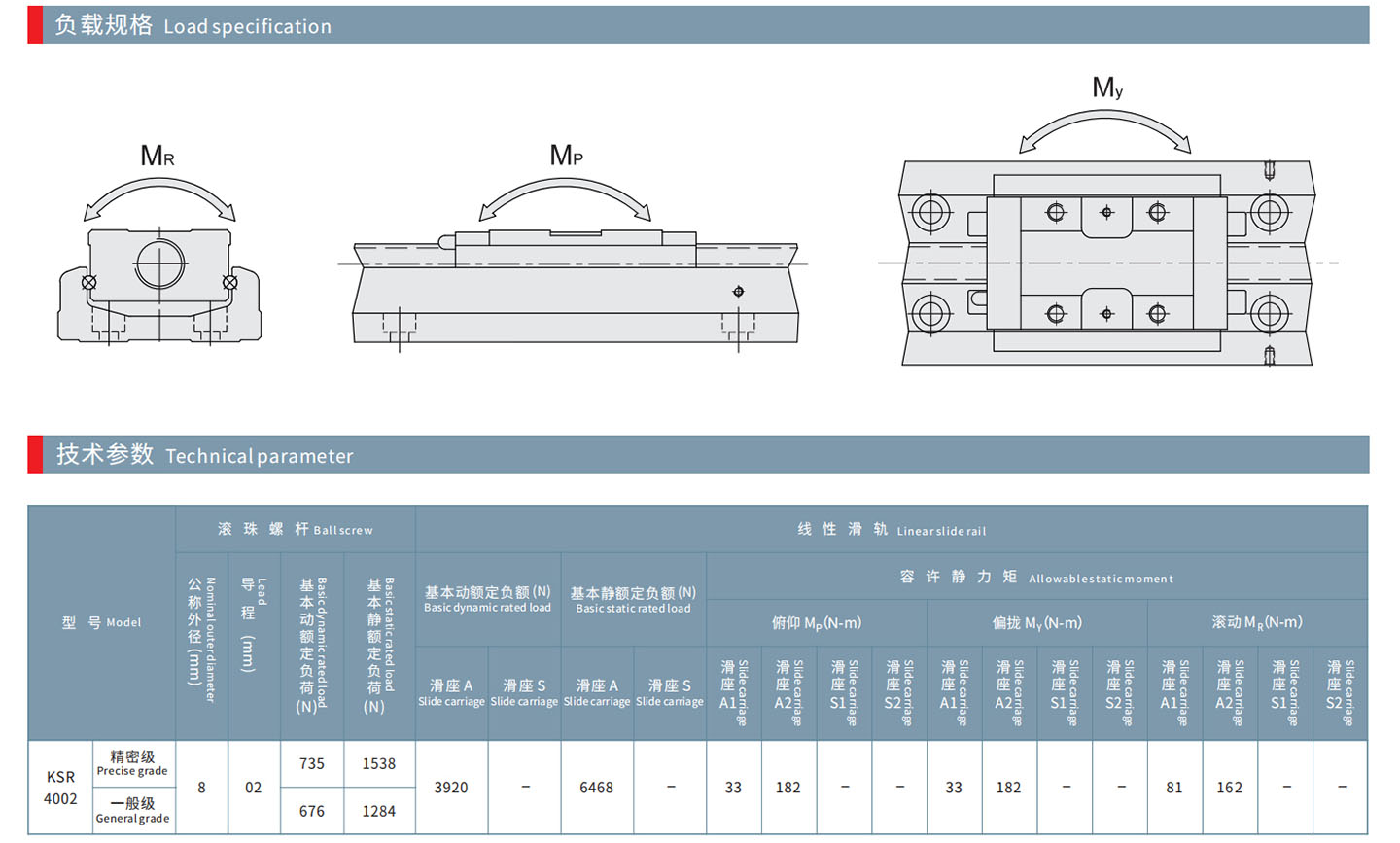

Features

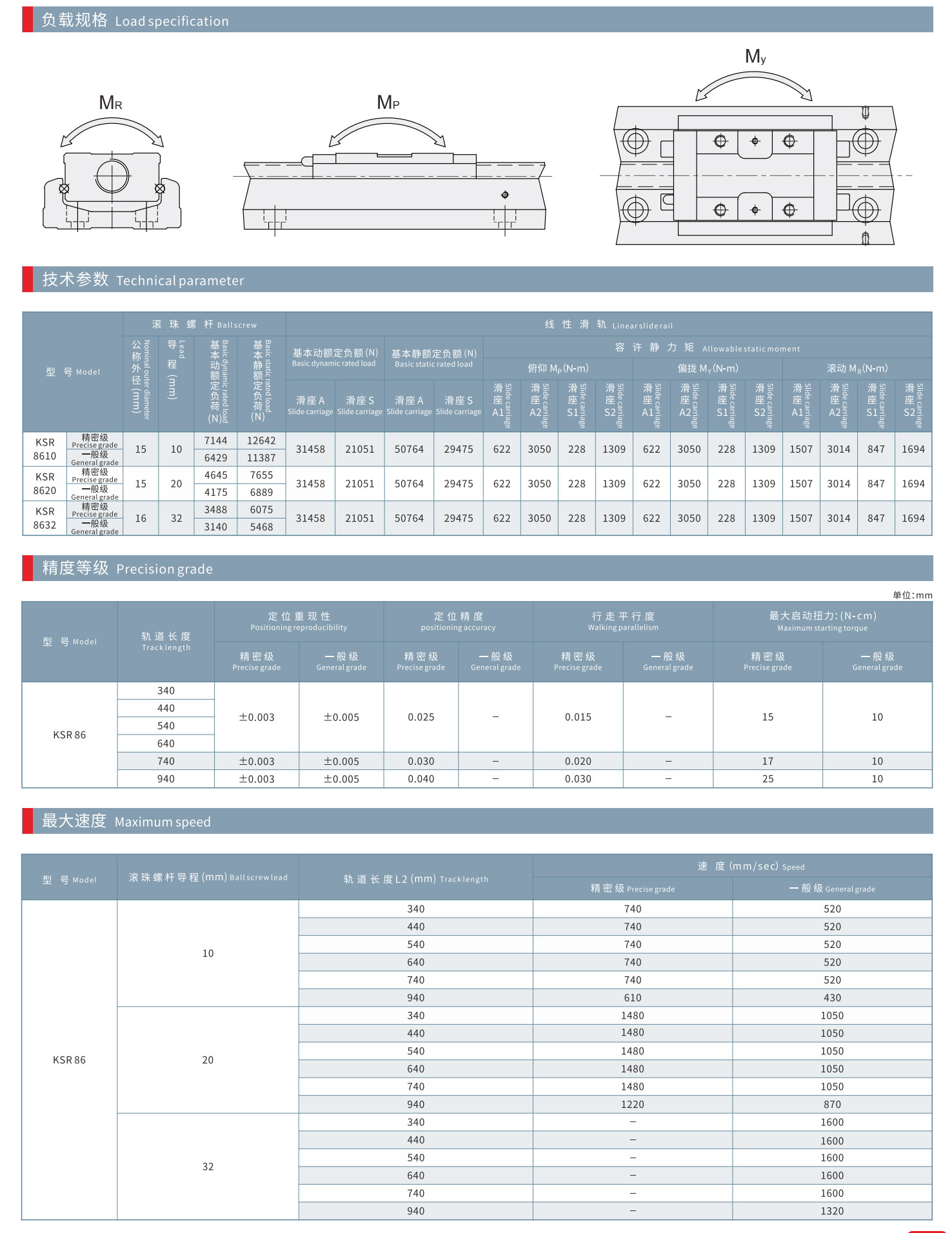

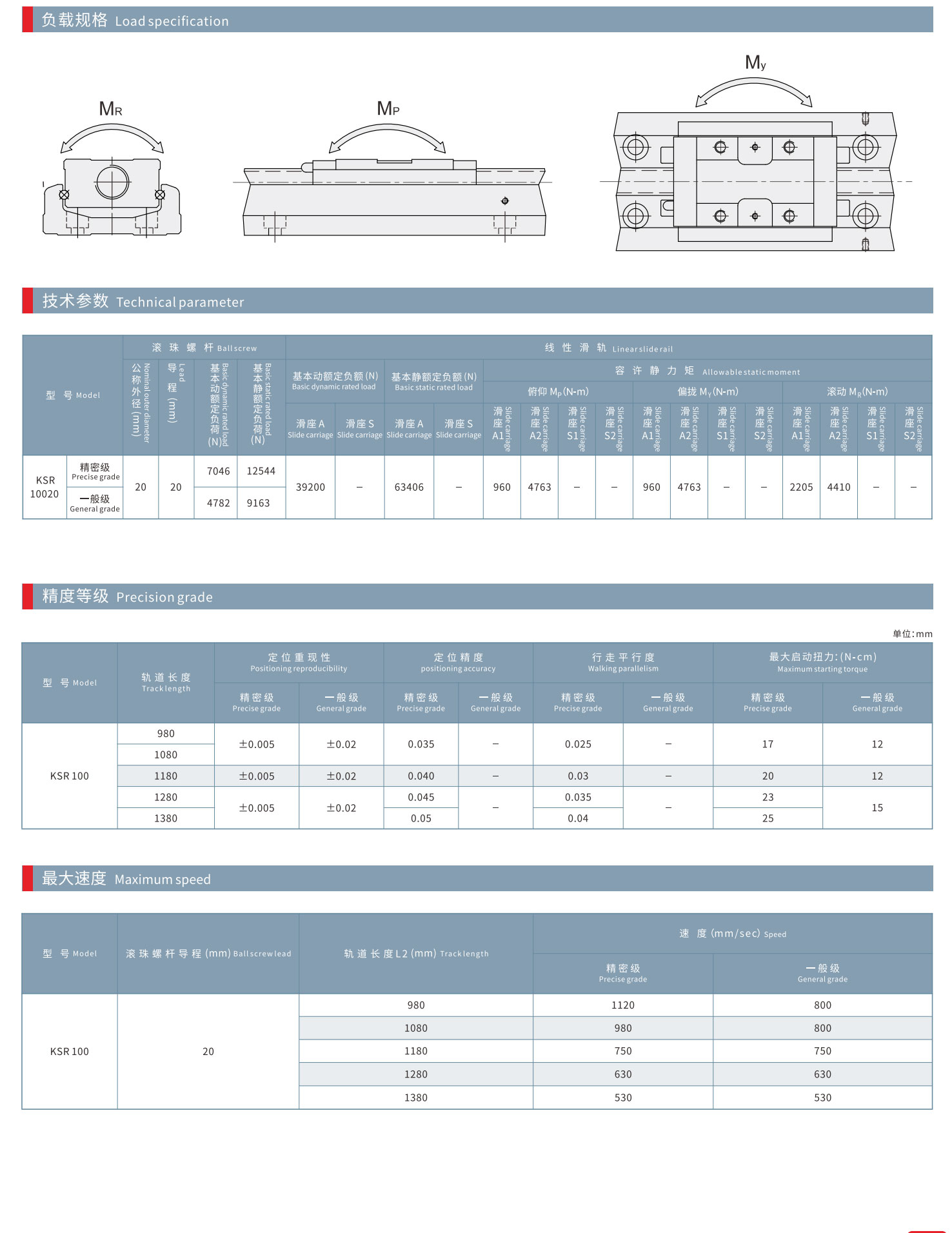

Repeated Positioning Accuracy: ±0.005mm

Basic Static Rated Load: 12642N

Basic Dynamic Rated Load: 7144N

Stroke: 31 – 1128mm

Max Speed: 1000mm/s

The high-precision ball screw is used as the transmission structure, and the U-shaped track is matched with the optimized design. As a guide structure, to ensure the accuracy and rigidity requirements.

The contact surface between the ball and the bead groove adopts a 2-row Goethe tooth type. The design has the characteristics of 45-degree contact angle, which enables the steel-based module to withstand four directions. The ability of equal load.

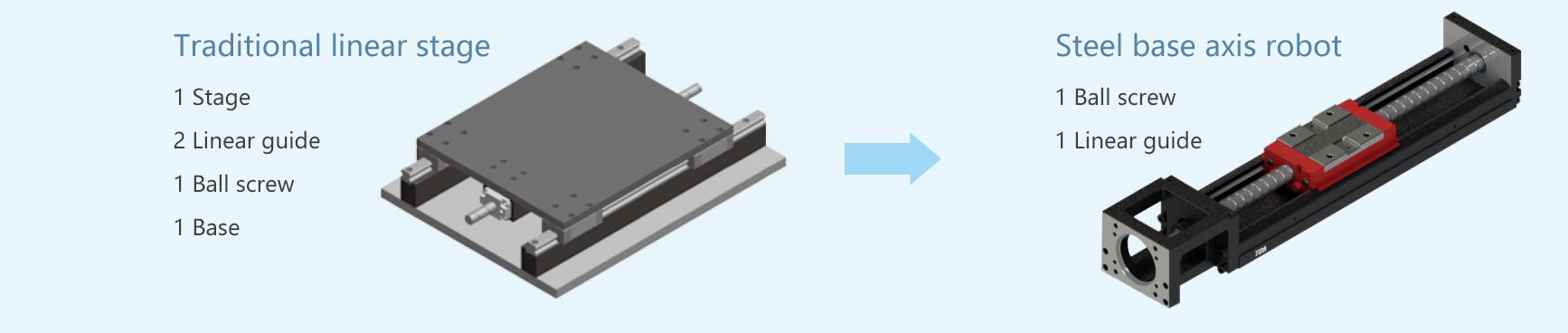

Through modular design, the steel base module integrates ball screw and U-shaped rail, which can save the traditional actuating platform from having to go through the selection of guiding and driving components, installation and verification, large volume and occupying space. Therefore, the steel-based module can provide the characteristics of quick selection, installation, compact size, high rigidity and so on, which can greatly reduce the use space and time of the client.