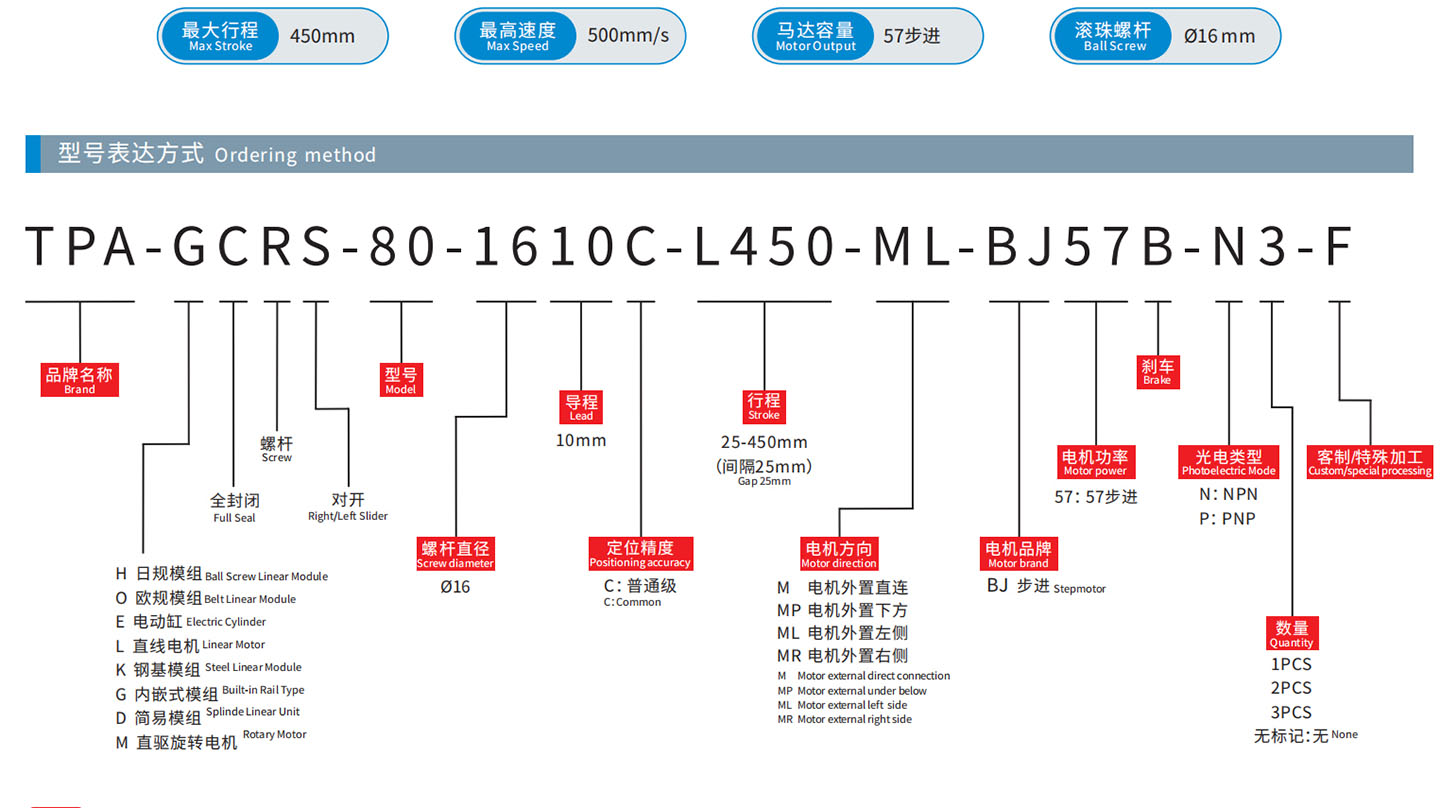

Based on the module of GCR series, we added a slider on the guide rail, so that the two sliders can both synchronize motion or reverse. This is the GCRS series, which retains the advantages of the GCR while offering greater efficiency of movement.

Features

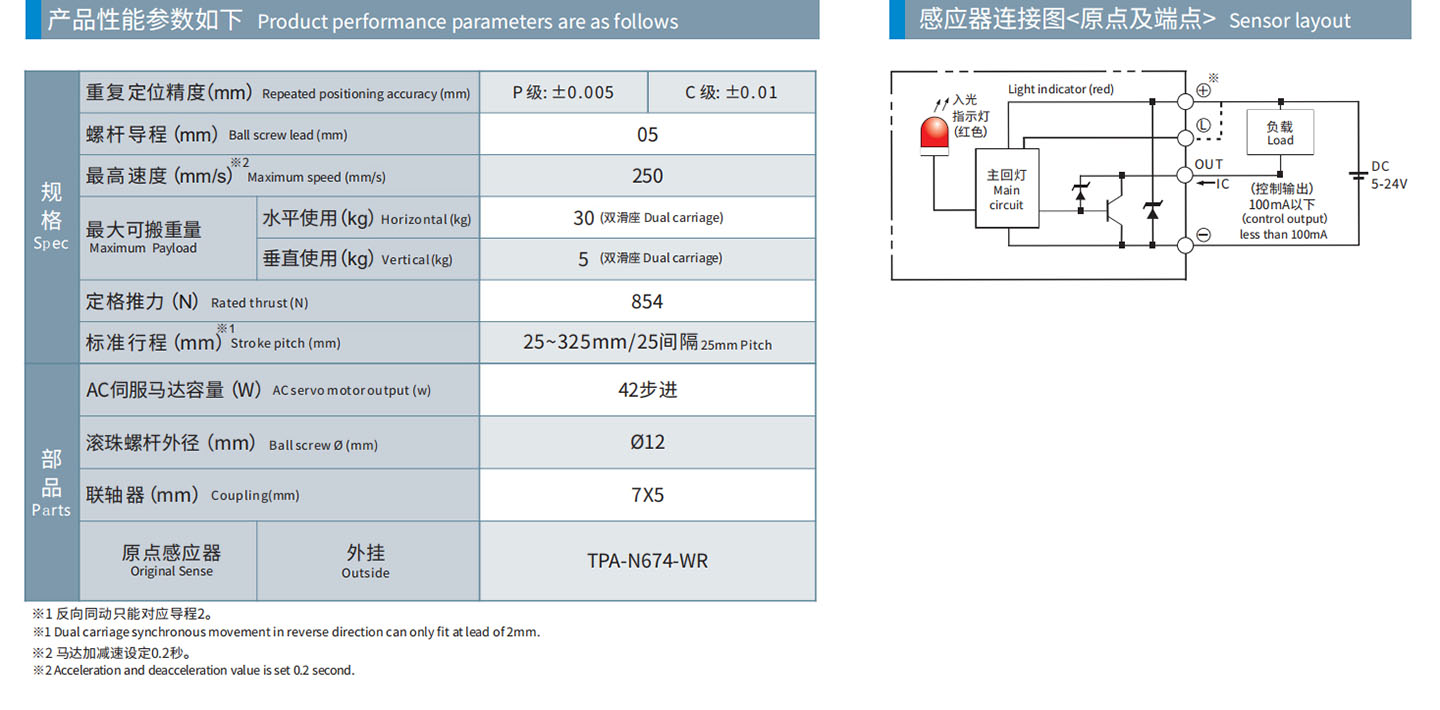

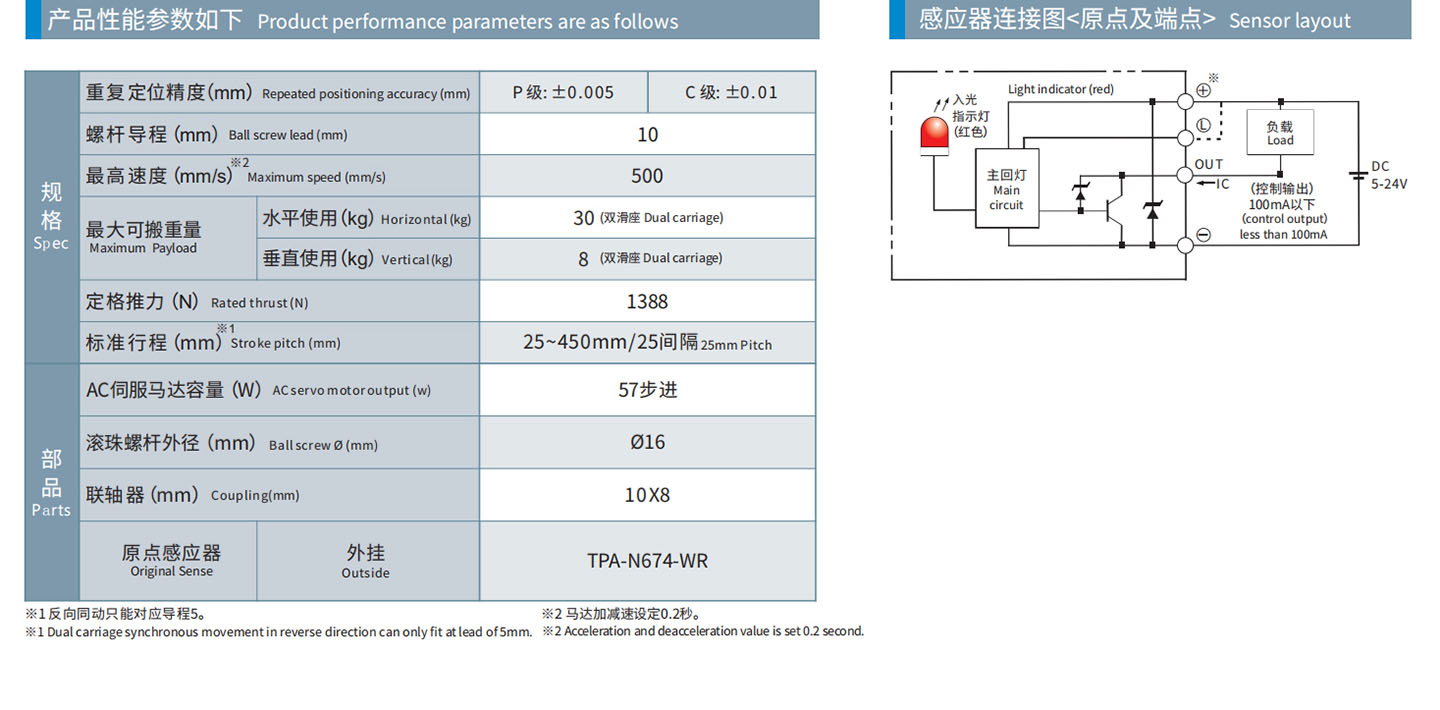

Repeated Positioning Accuracy: ±0.005mm

Max Payload(Horizontal): 30kg

Max Payload(Vertical): 10kg

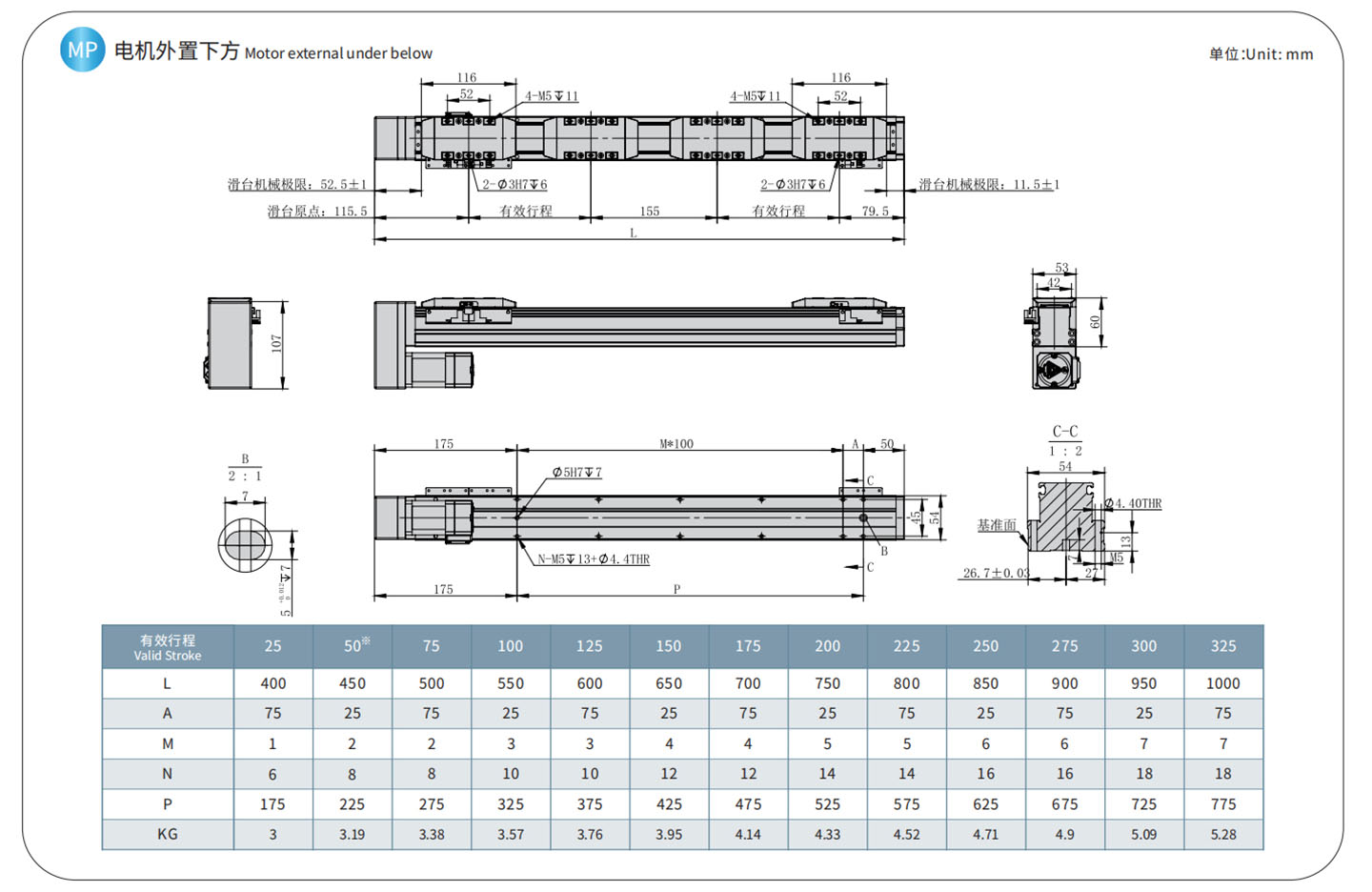

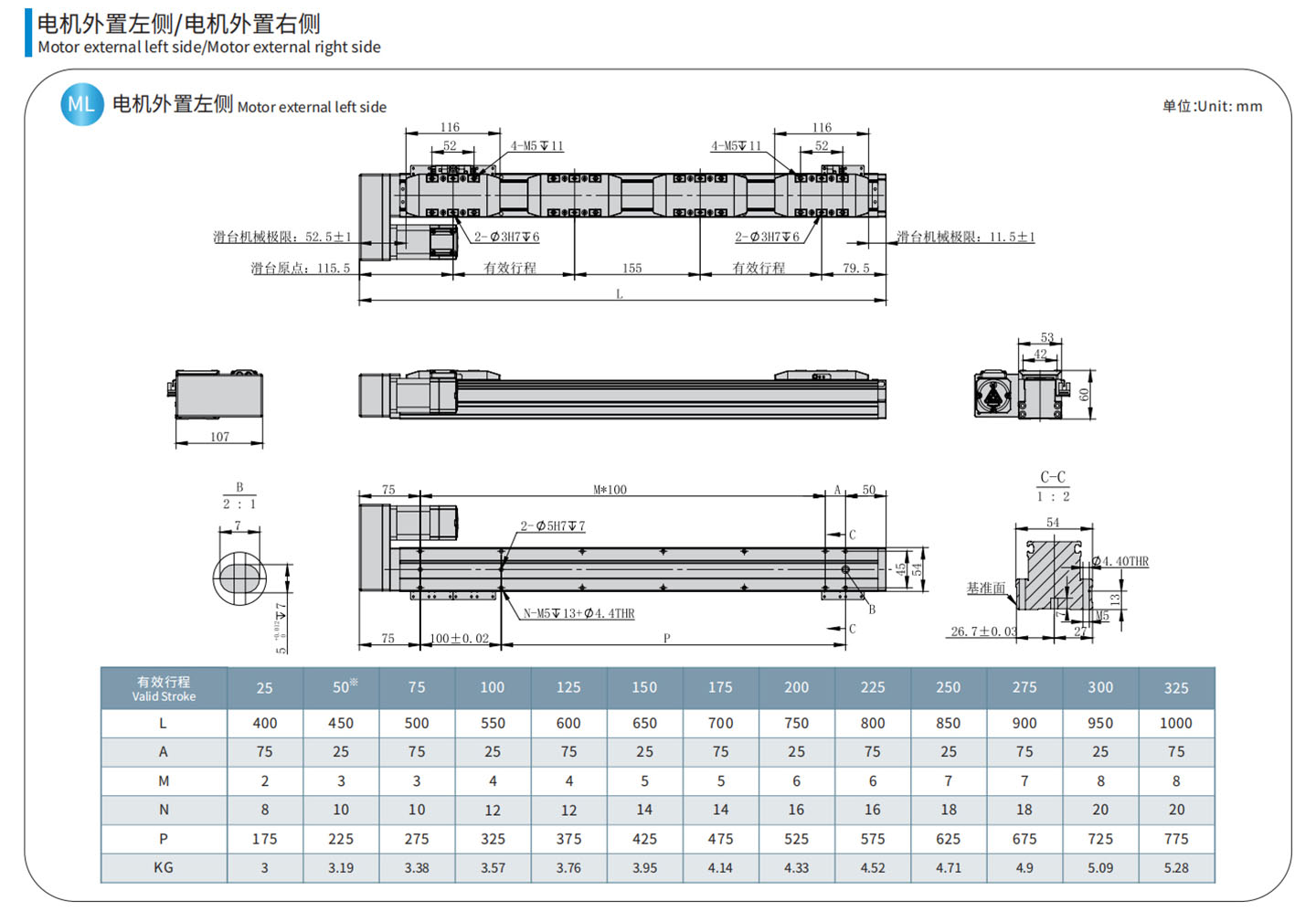

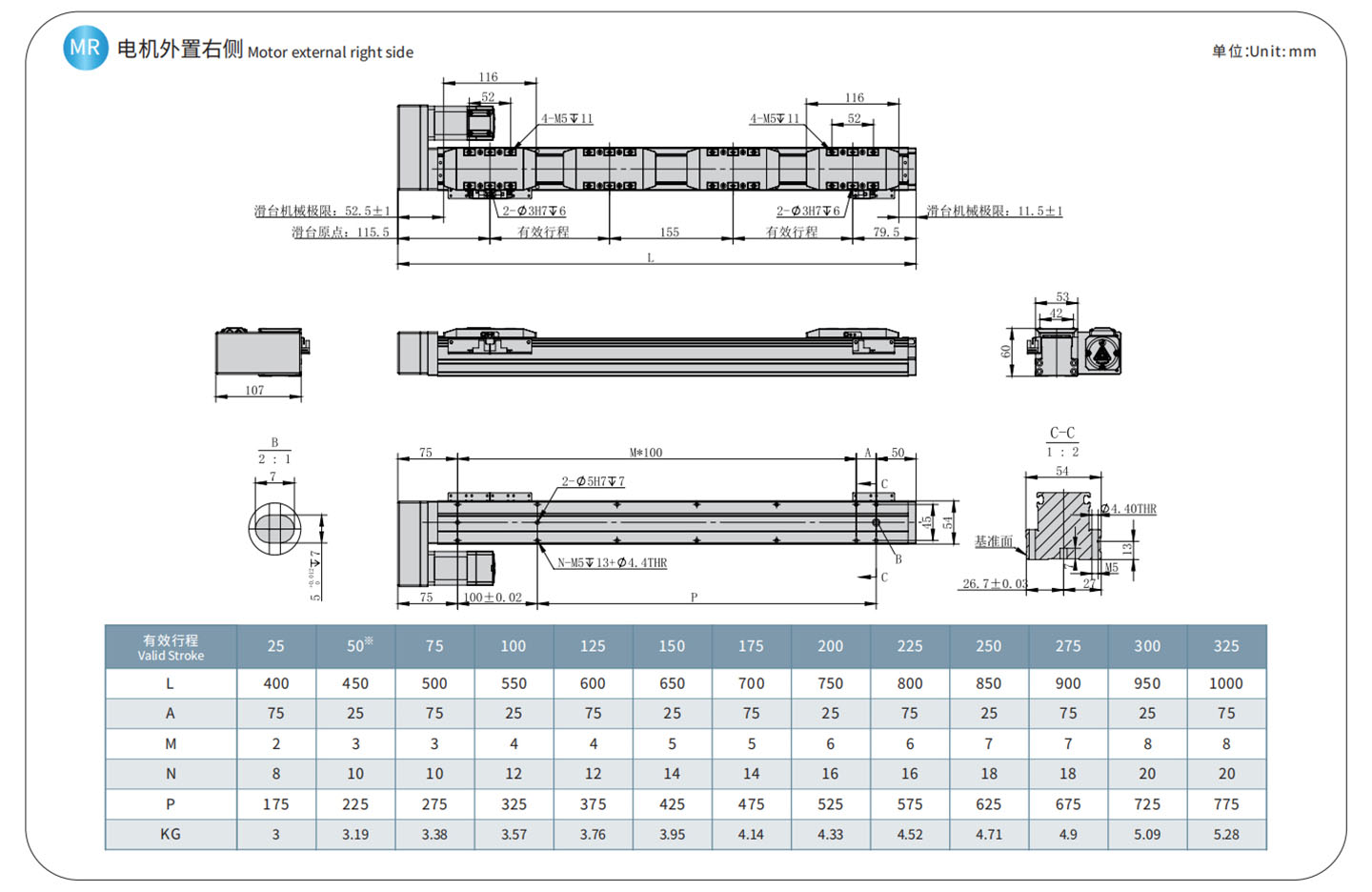

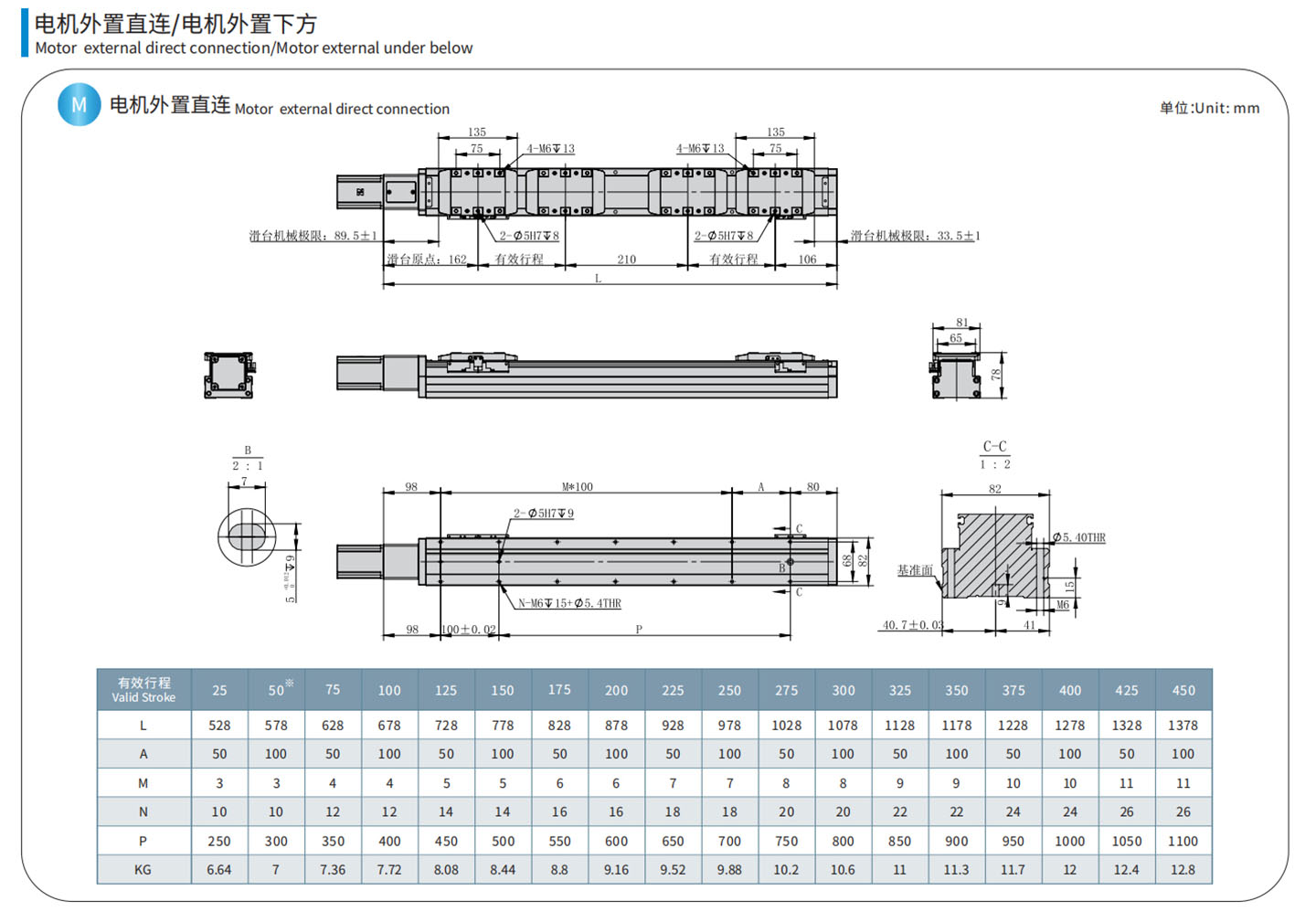

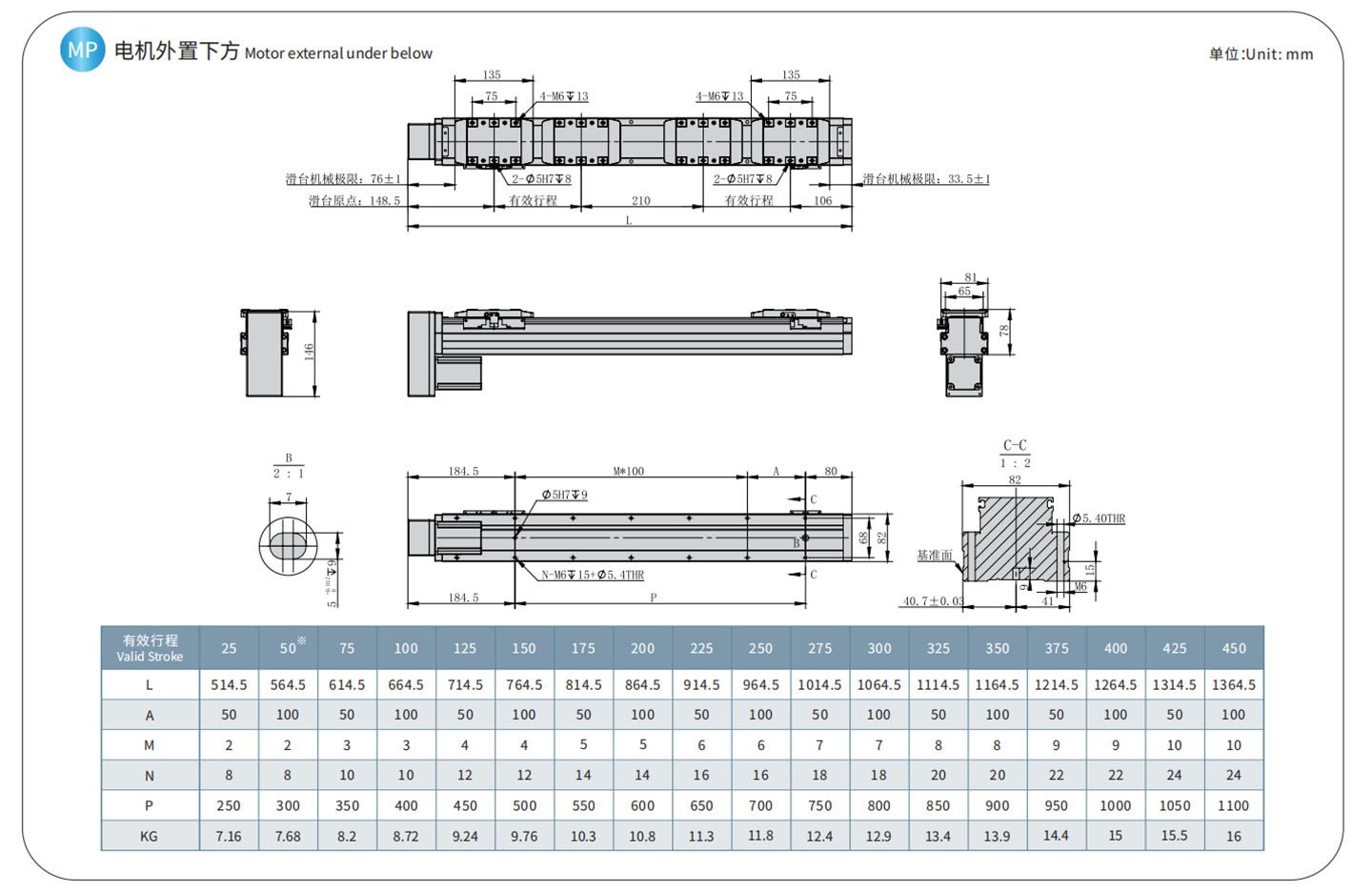

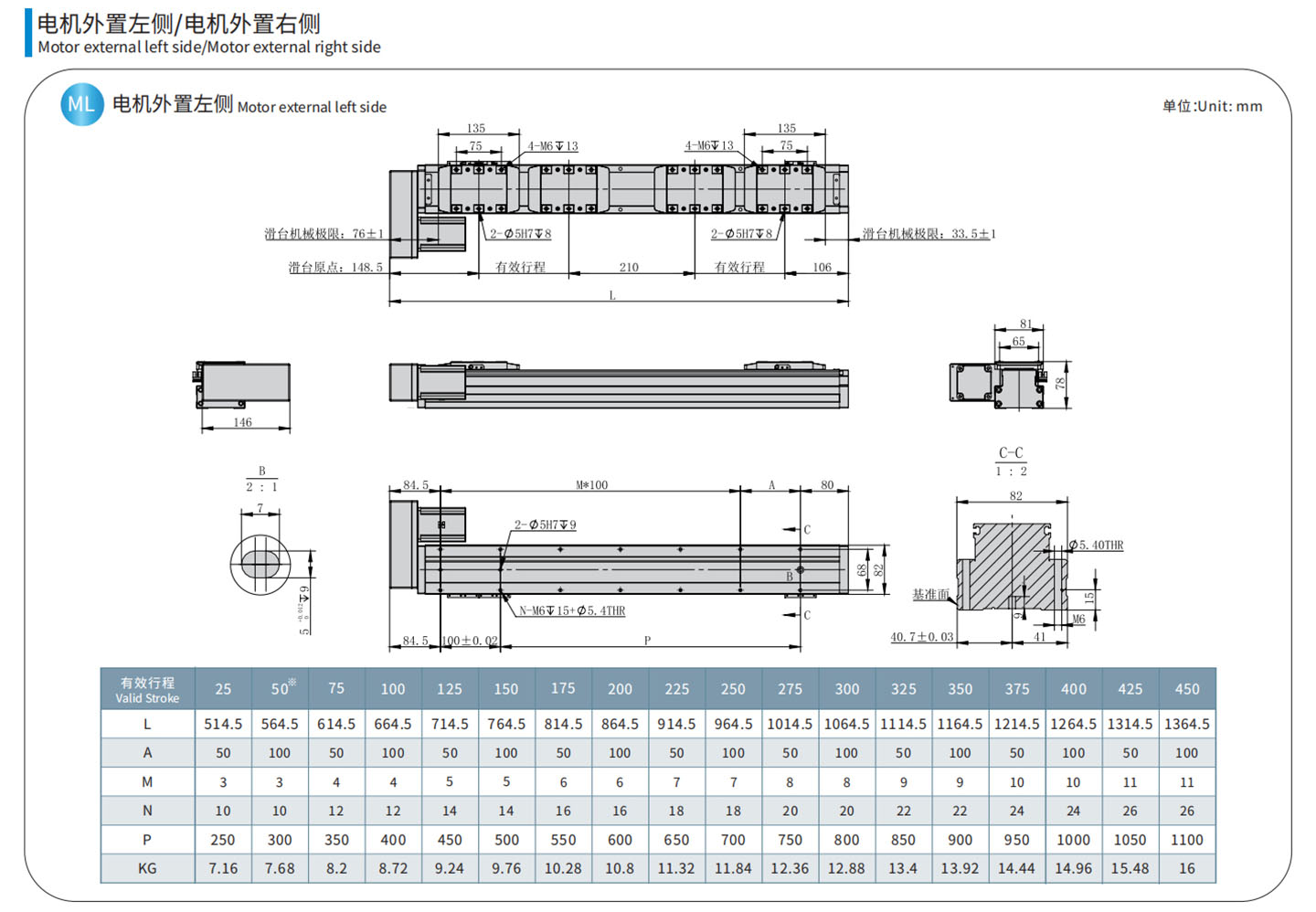

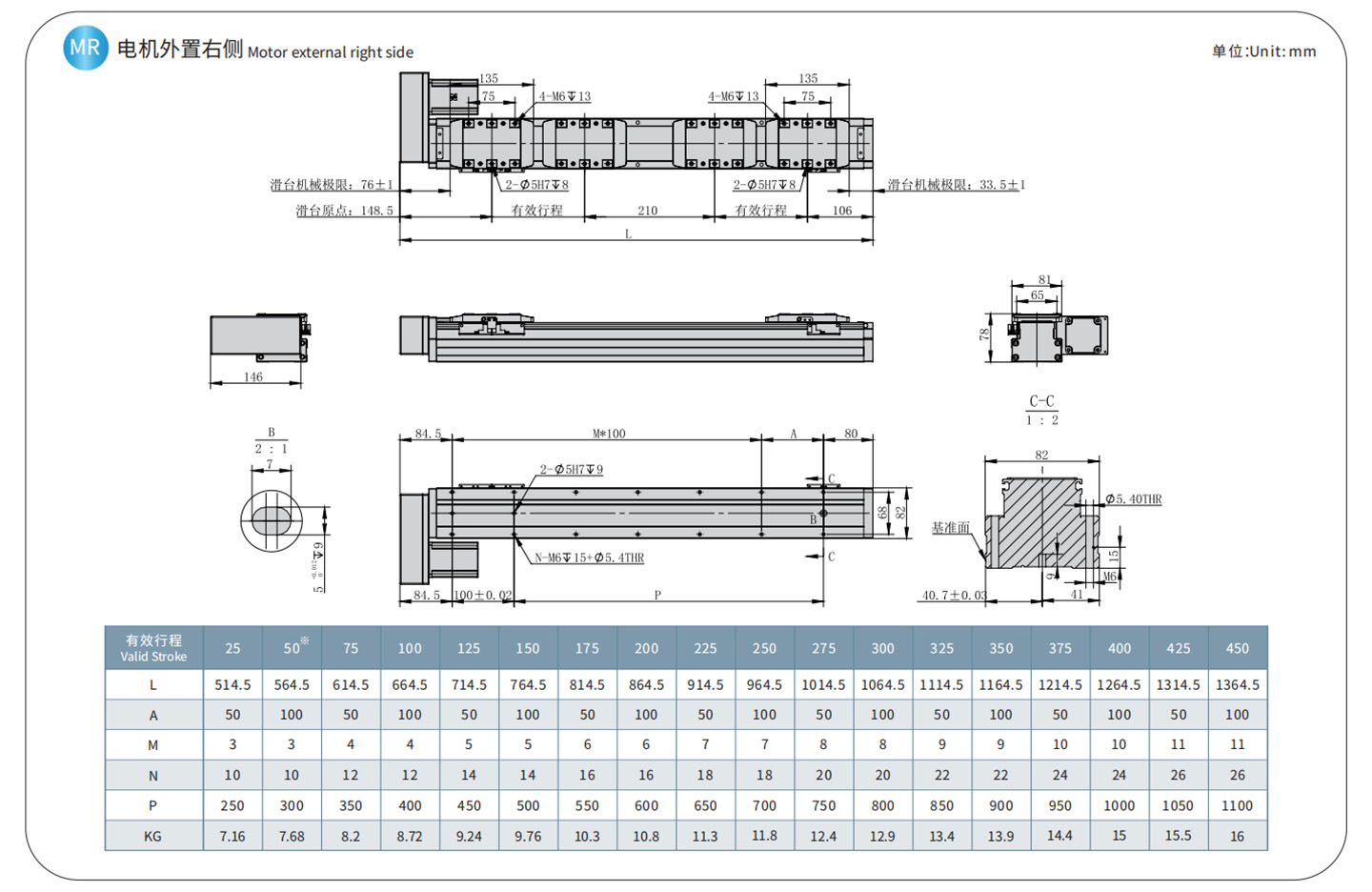

Stroke: 25 – 450mm

Max Speed: 500mm/s

When designing, the ball nut and the ball slider are fitted on the entire sliding seat, which has good consistency and higher precision. At the same time, a round ball nut is omitted, and the weight is reduced by 5%.

The aluminum base of the main body is embedded with steel bars and then the groove is ground. Since the original ball guide rail structure is omitted, the structure can be made more compact in the width direction and height direction, and the weight is about 25% lighter than that of the aluminum base module in the same industry.

Without changing the size of the overall structure, the sliding seat is integrally cast steel. According to the characteristics of the overall structure, a special 12mm outer diameter ball nut circulator is specially designed for this 40 model. The lead can be 20mm, and the vertical The load is increased by 50%, and the speed reaches 1m/s at the fastest.

The installation form is exposed, without dismantling the steel belt, two installation and use methods can be realized, lock-up and down-lock, and it is equipped with bottom installation pin holes and installation reference surface, which is convenient for customers to install and debug.

Considering the use of different motors during the design, a new type of turning connection method is specially designed, so that the same adapter board can be used in three different directions, which greatly improves the arbitrariness of customer needs.

More products