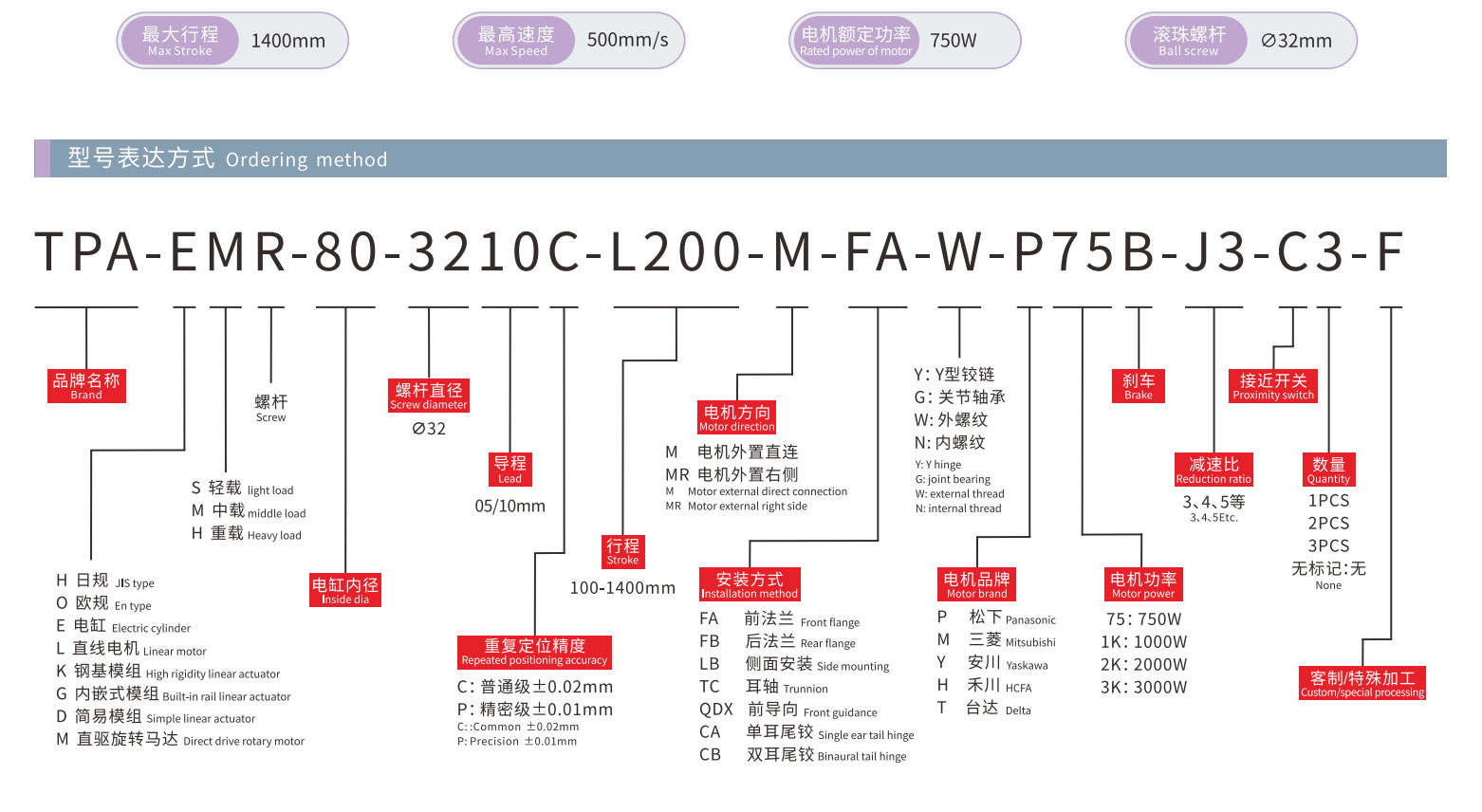

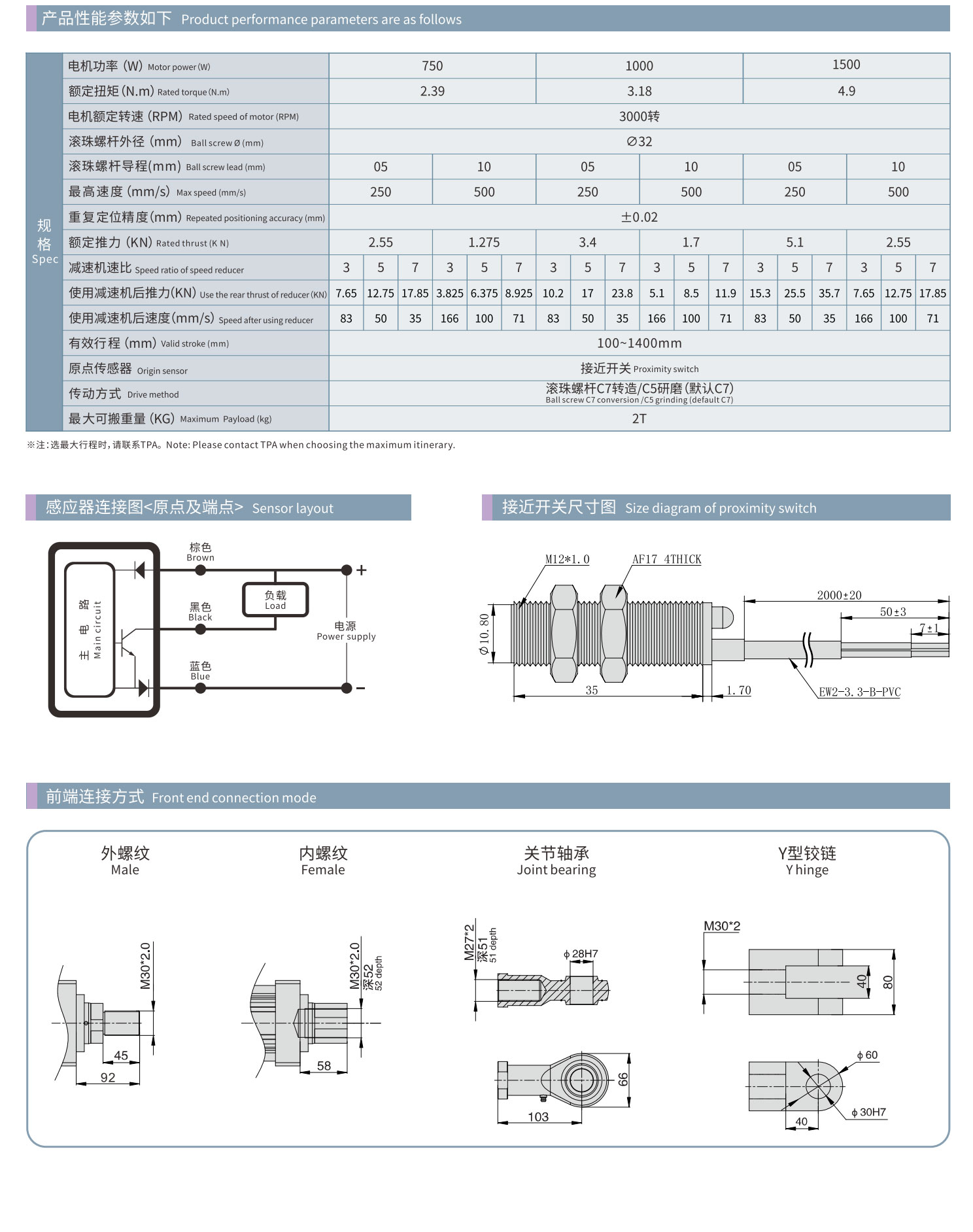

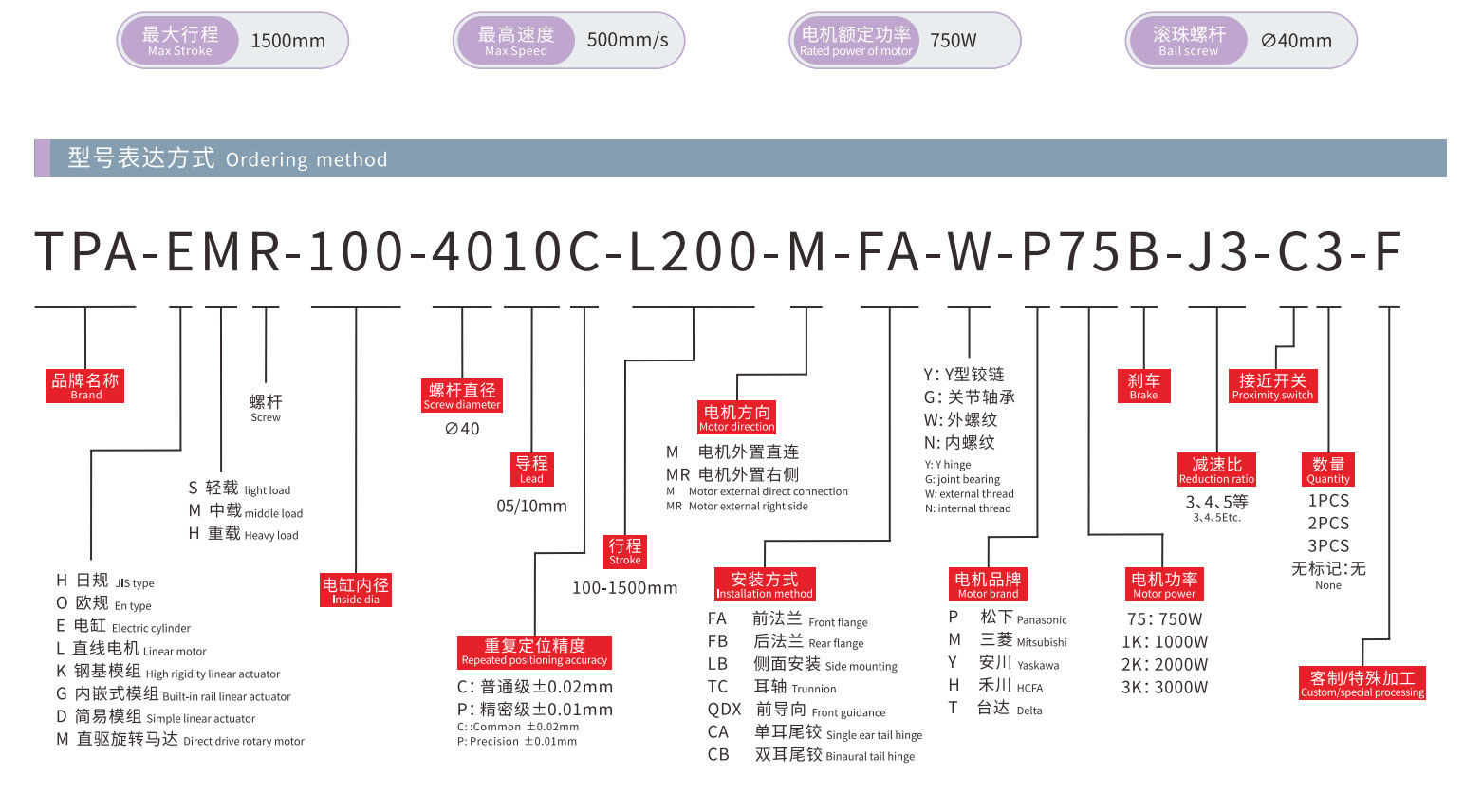

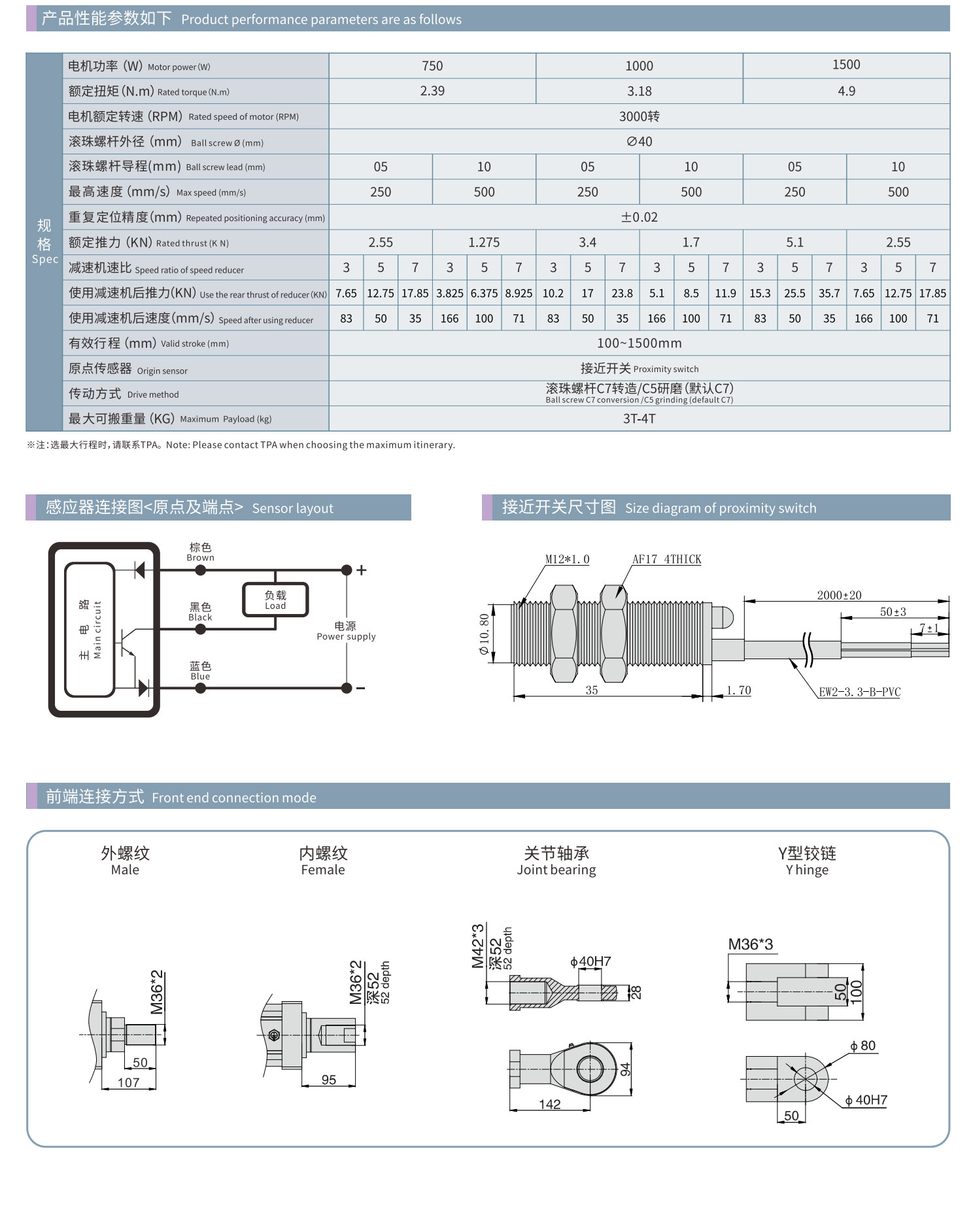

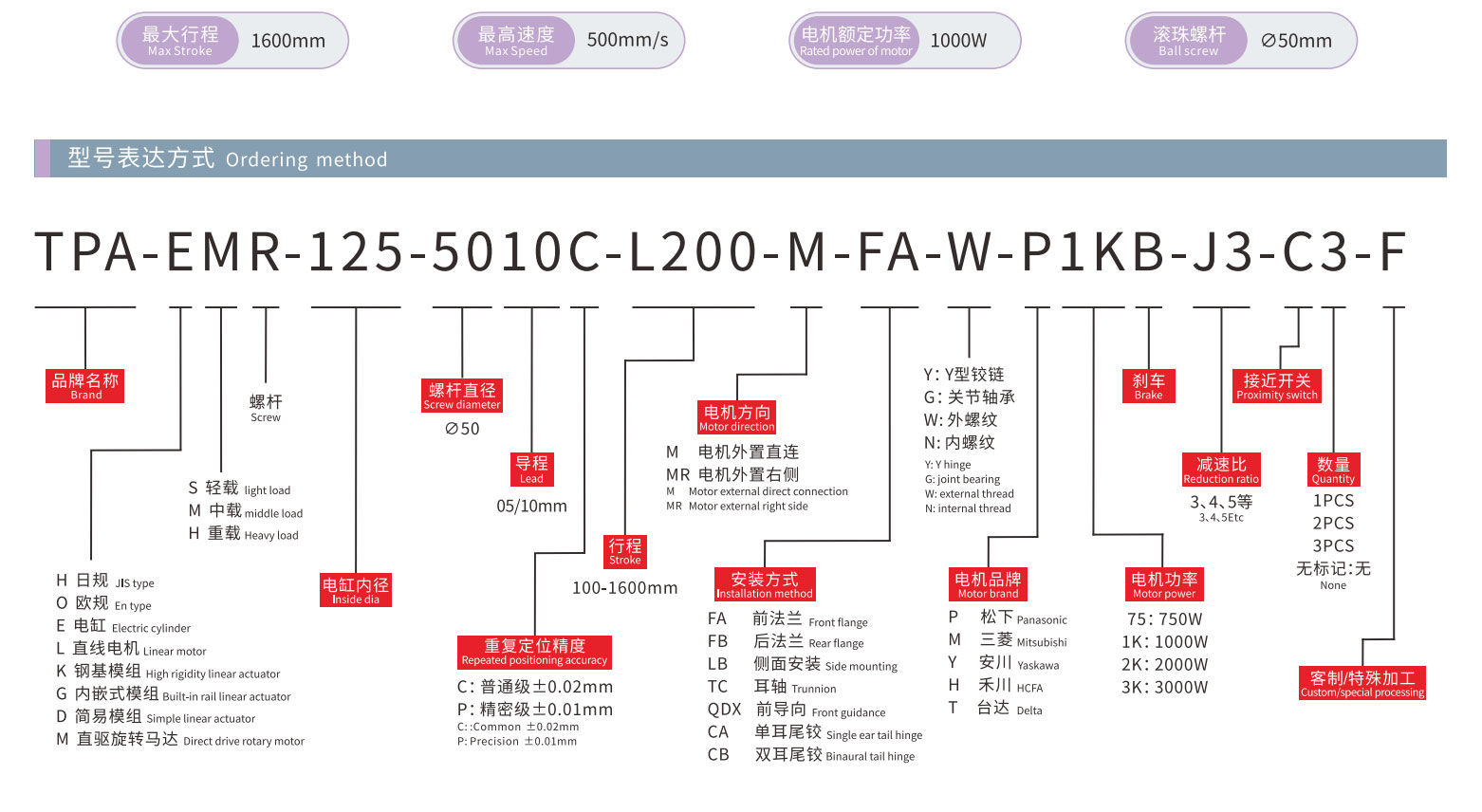

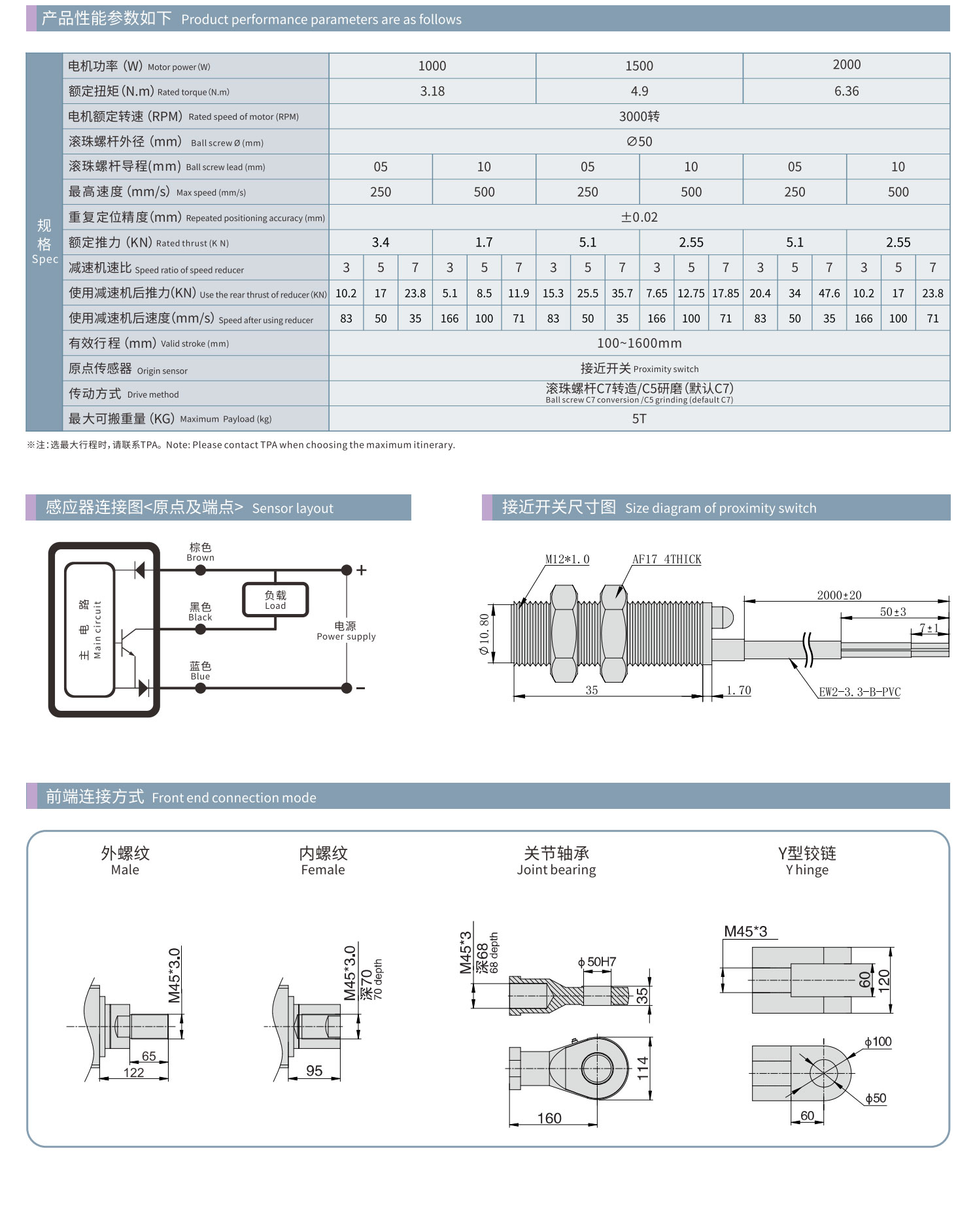

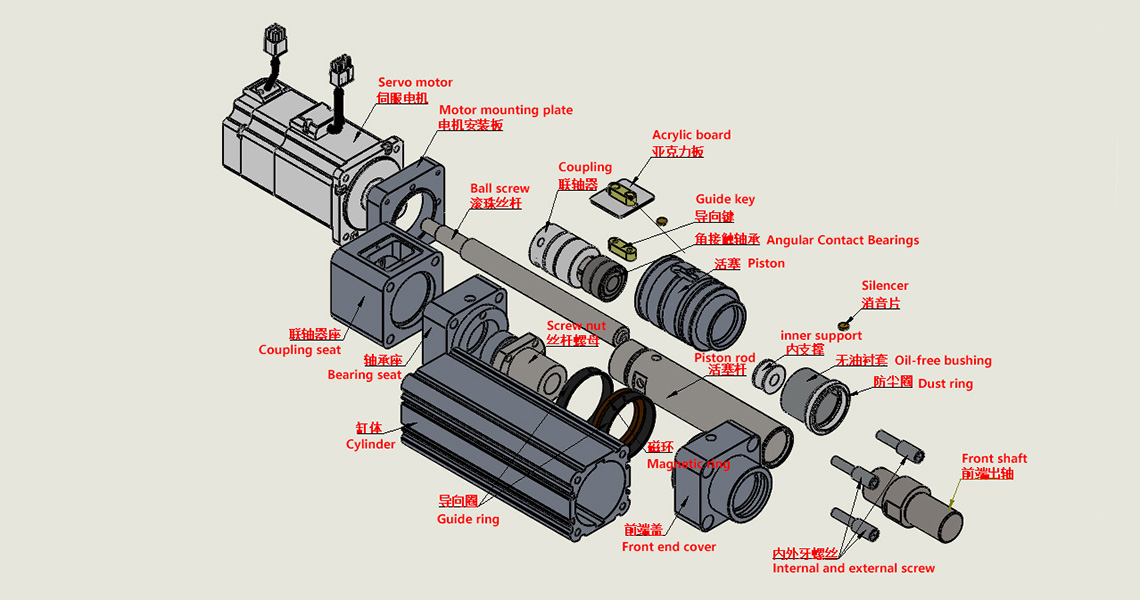

The EMR series electric actuator cylinder provides a thrust of up to 47600N and a stroke of 1600mm. It can also maintain the high precision of the servo motor and ball screw drive, and the repeat positioning accuracy can reach ±0.02mm. Only need to set and modify PLC parameters to complete precise push rod motion control. With its unique structure, the EMR electric actuator can work in complex environments. Its high power density, high transmission efficiency and long service life provide customers with a more economical solution for linear motion of the push rod, and it is easy to maintain. Only regular grease lubrication is required, saving a lot of maintenance costs.

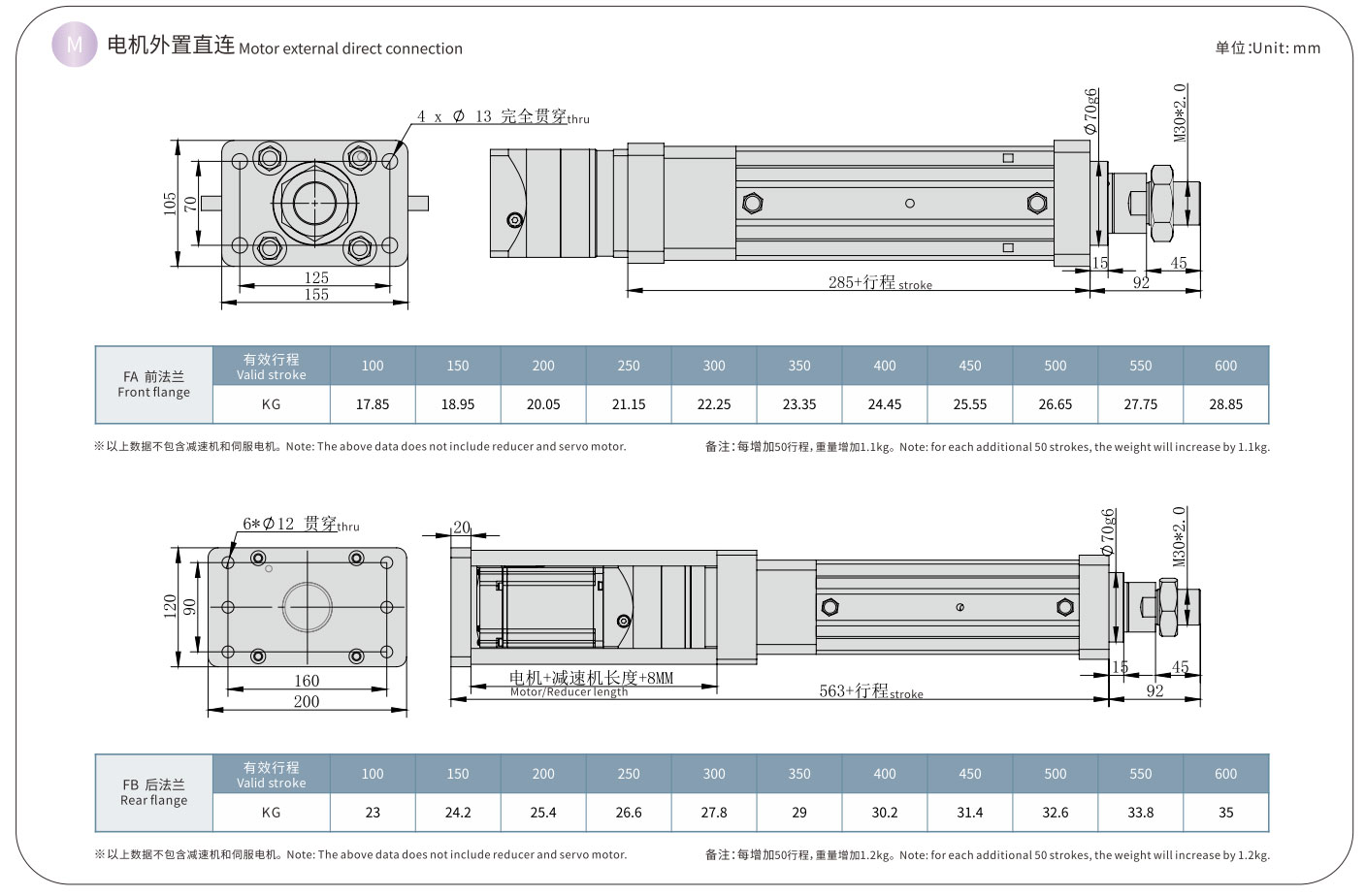

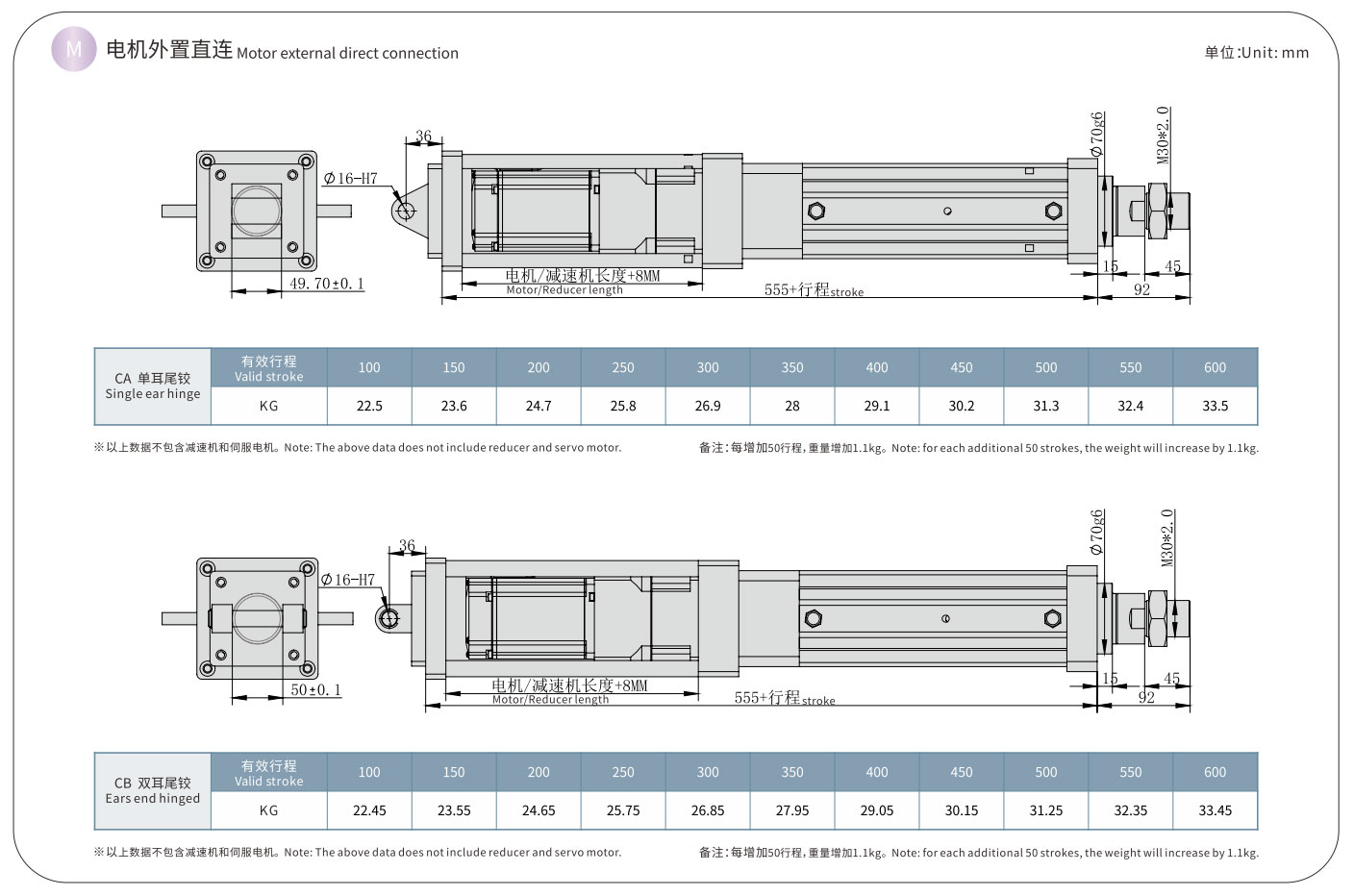

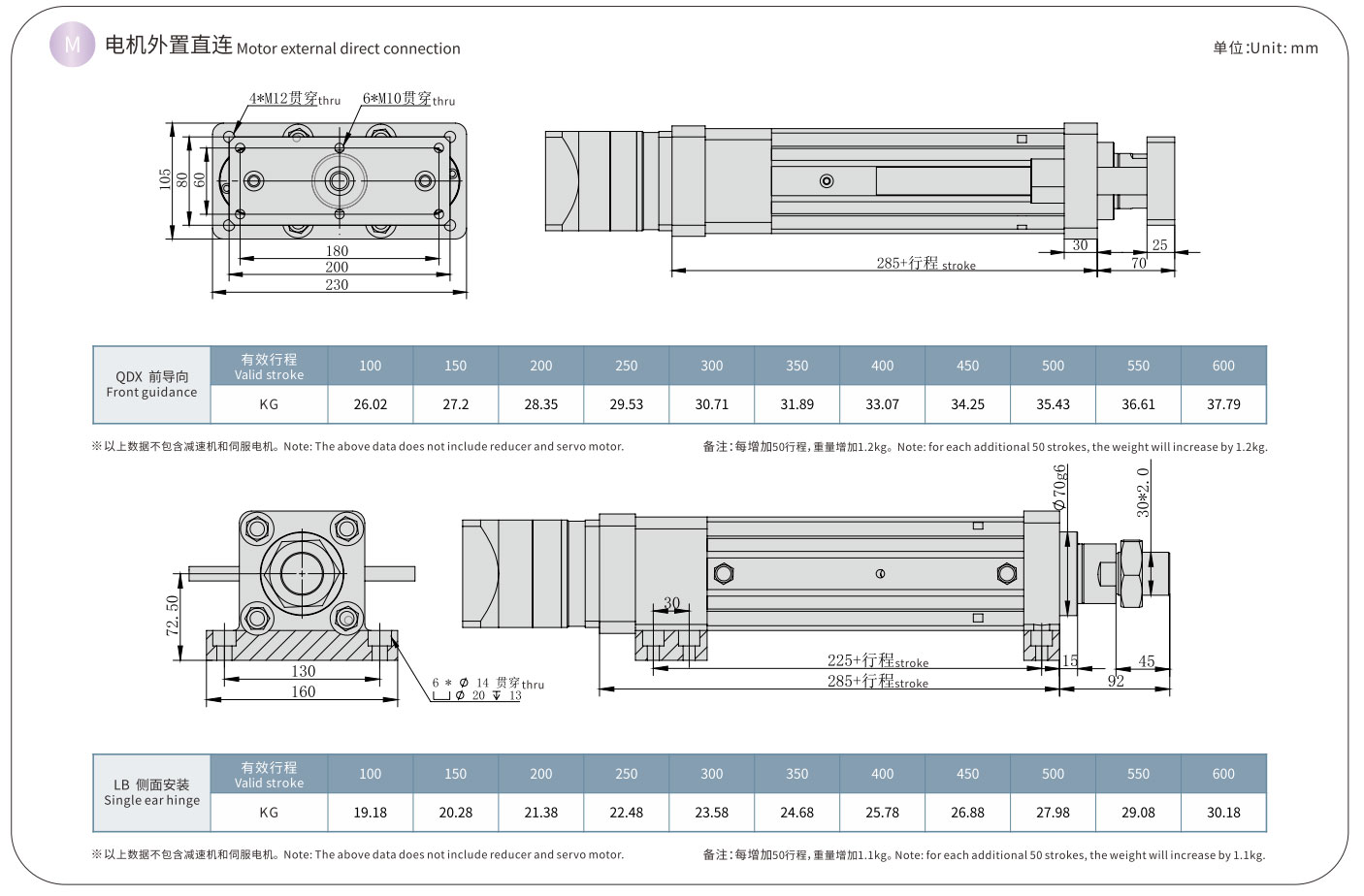

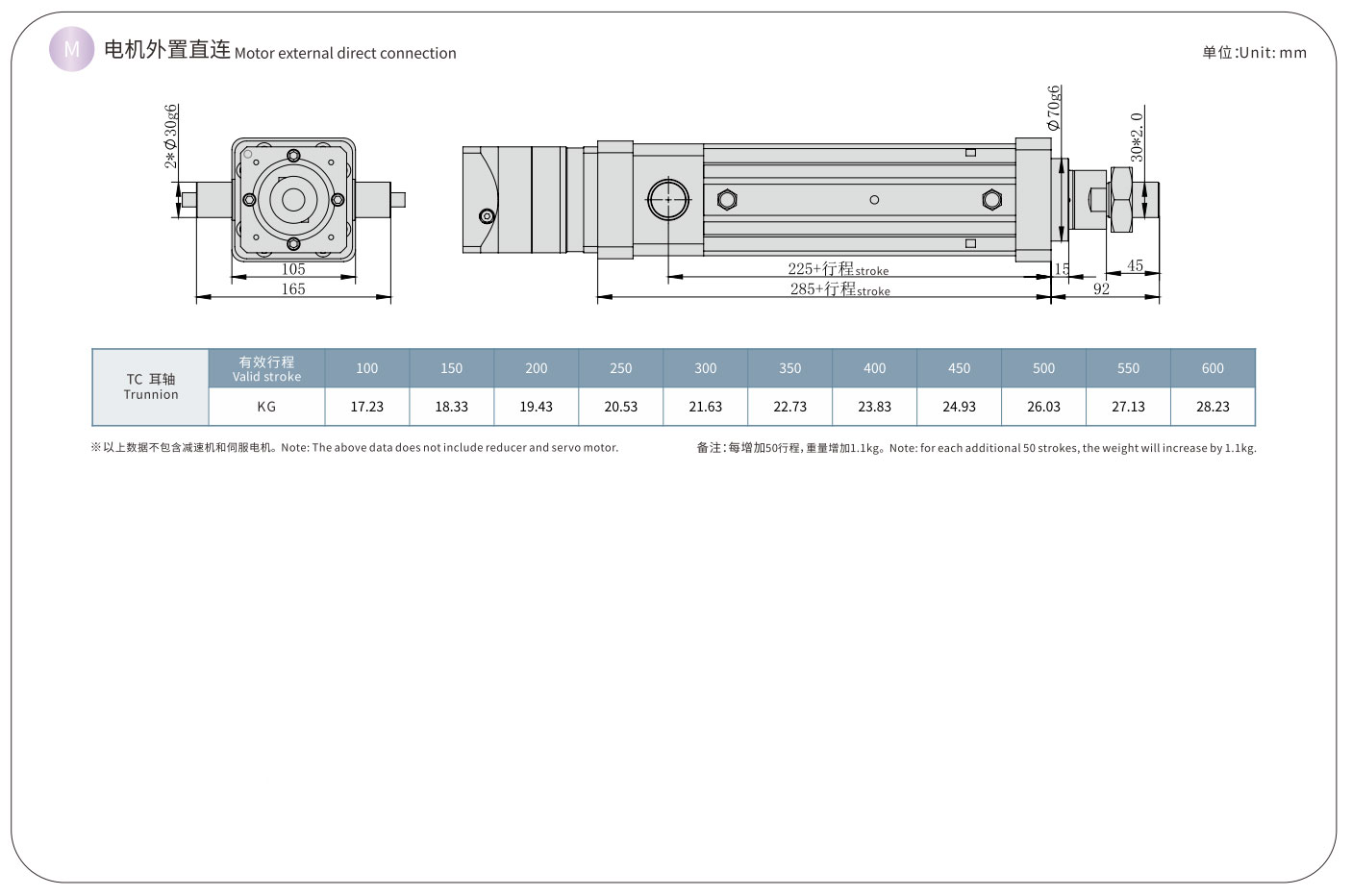

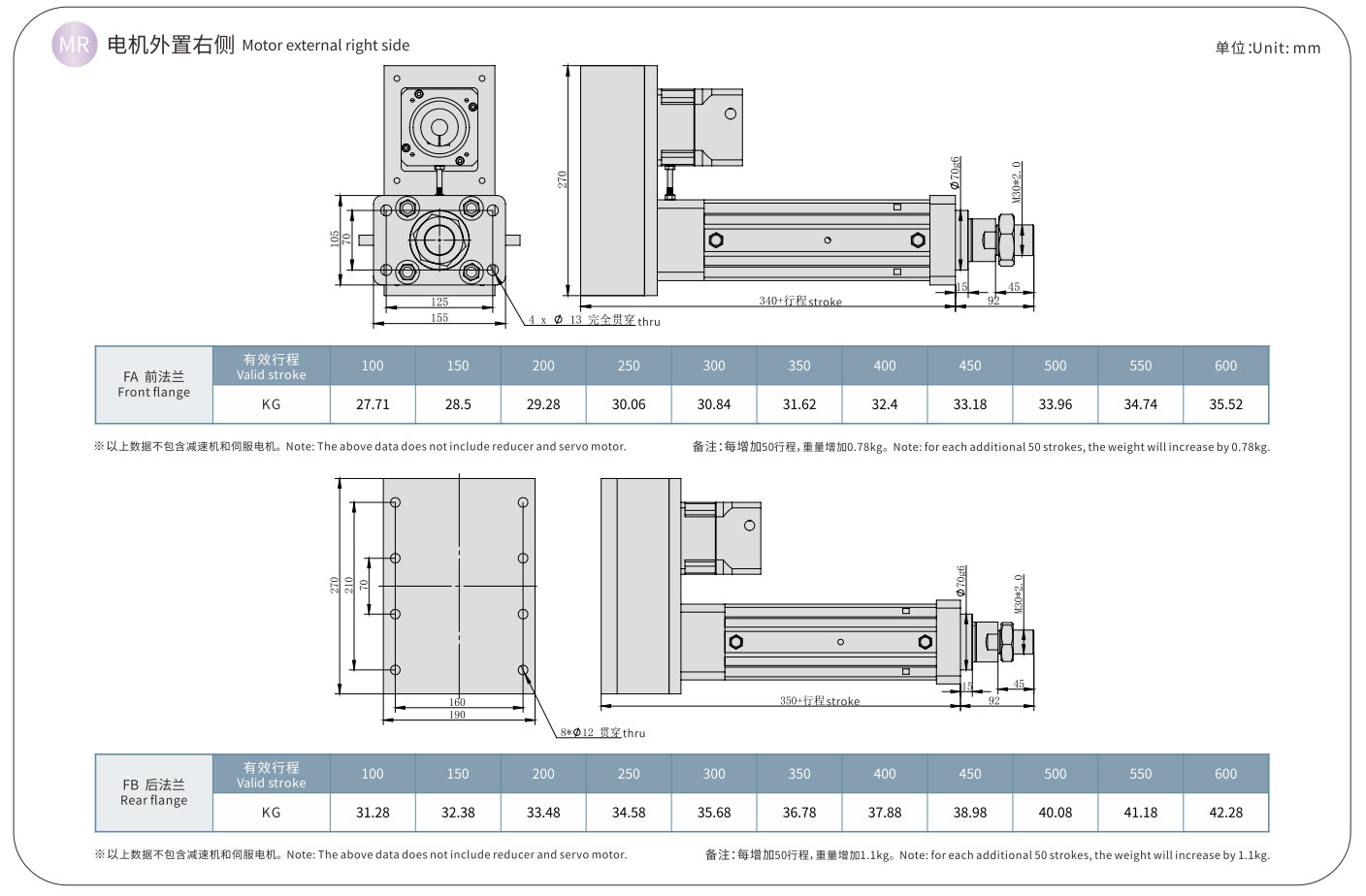

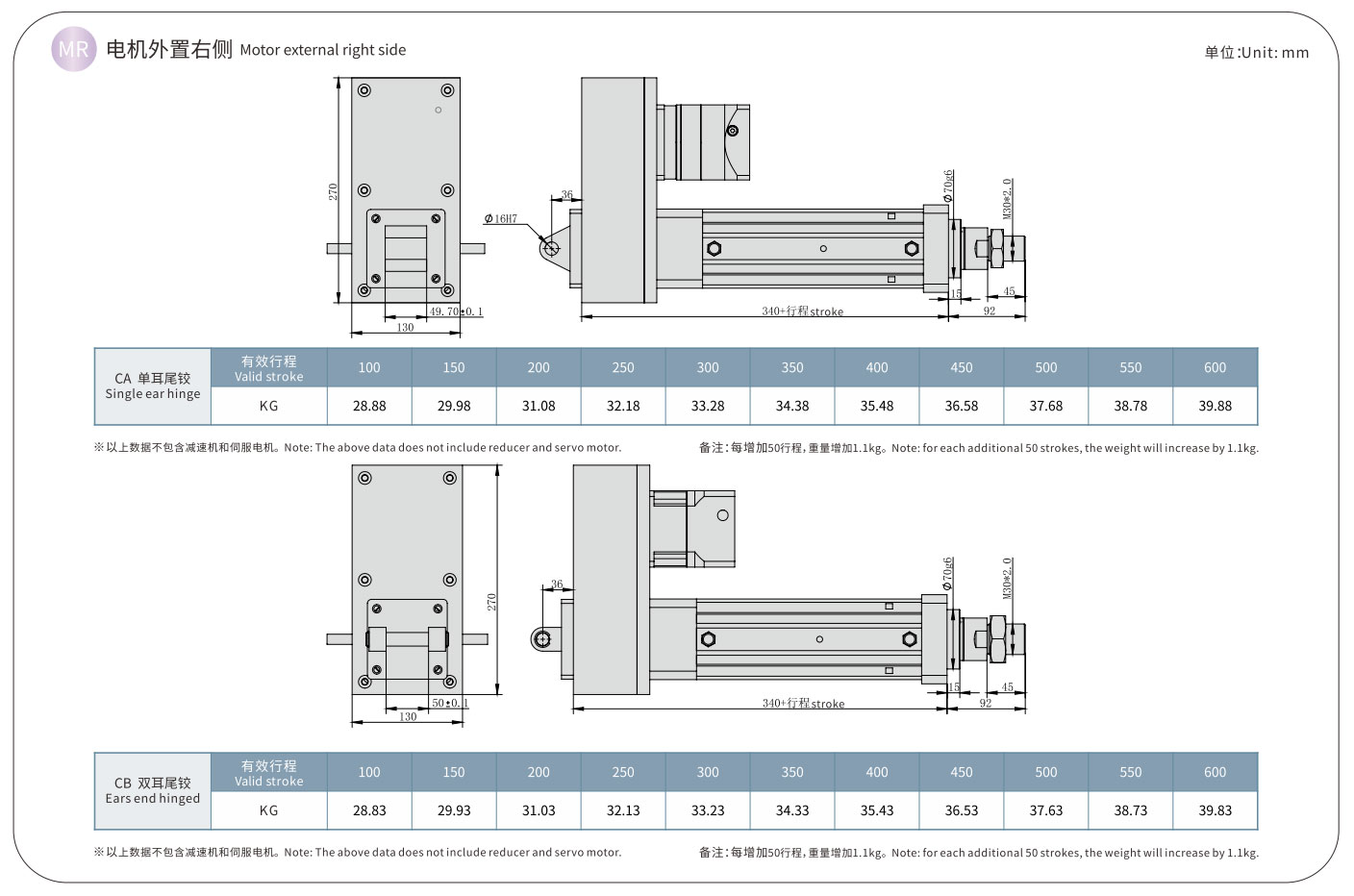

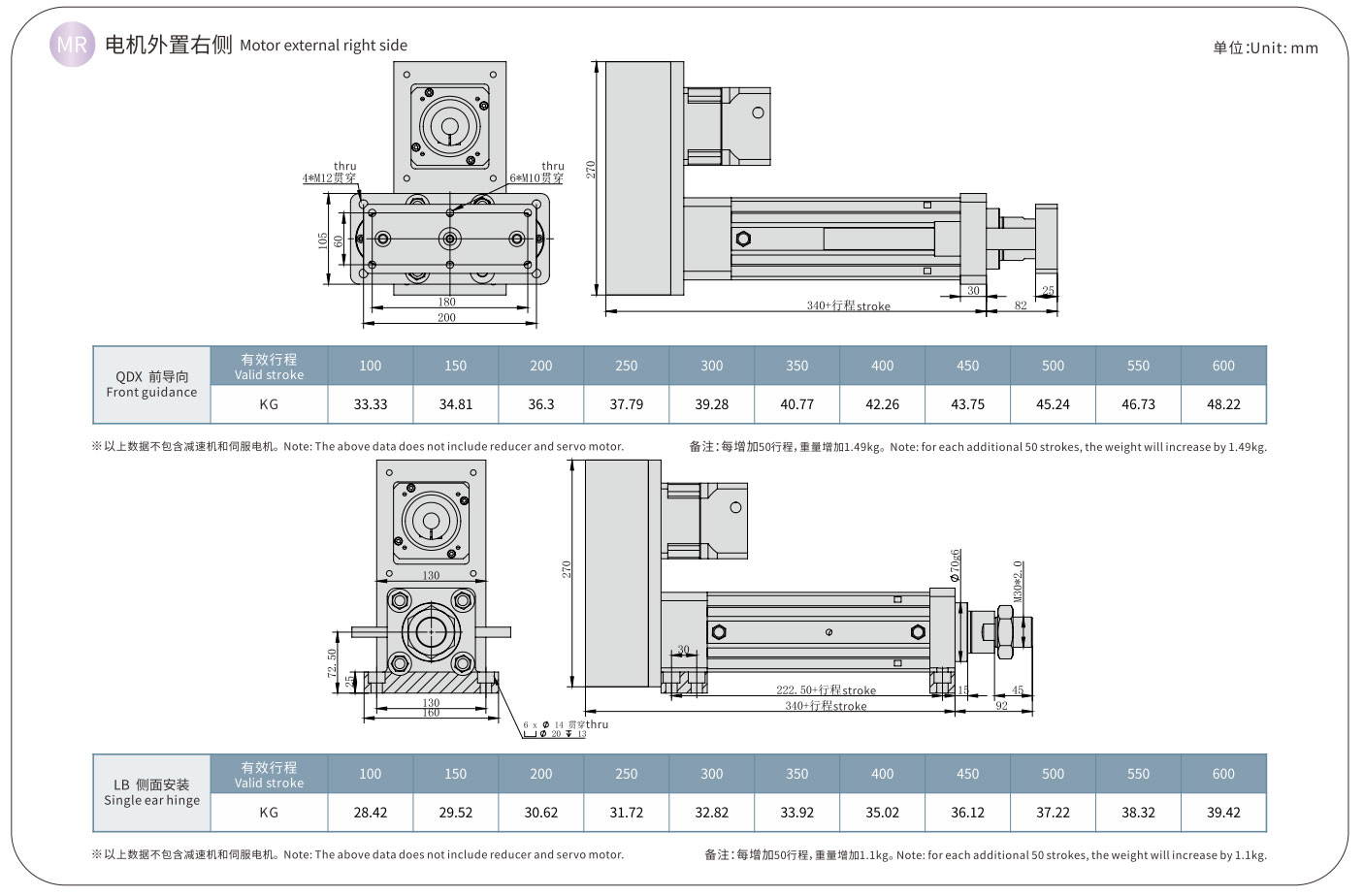

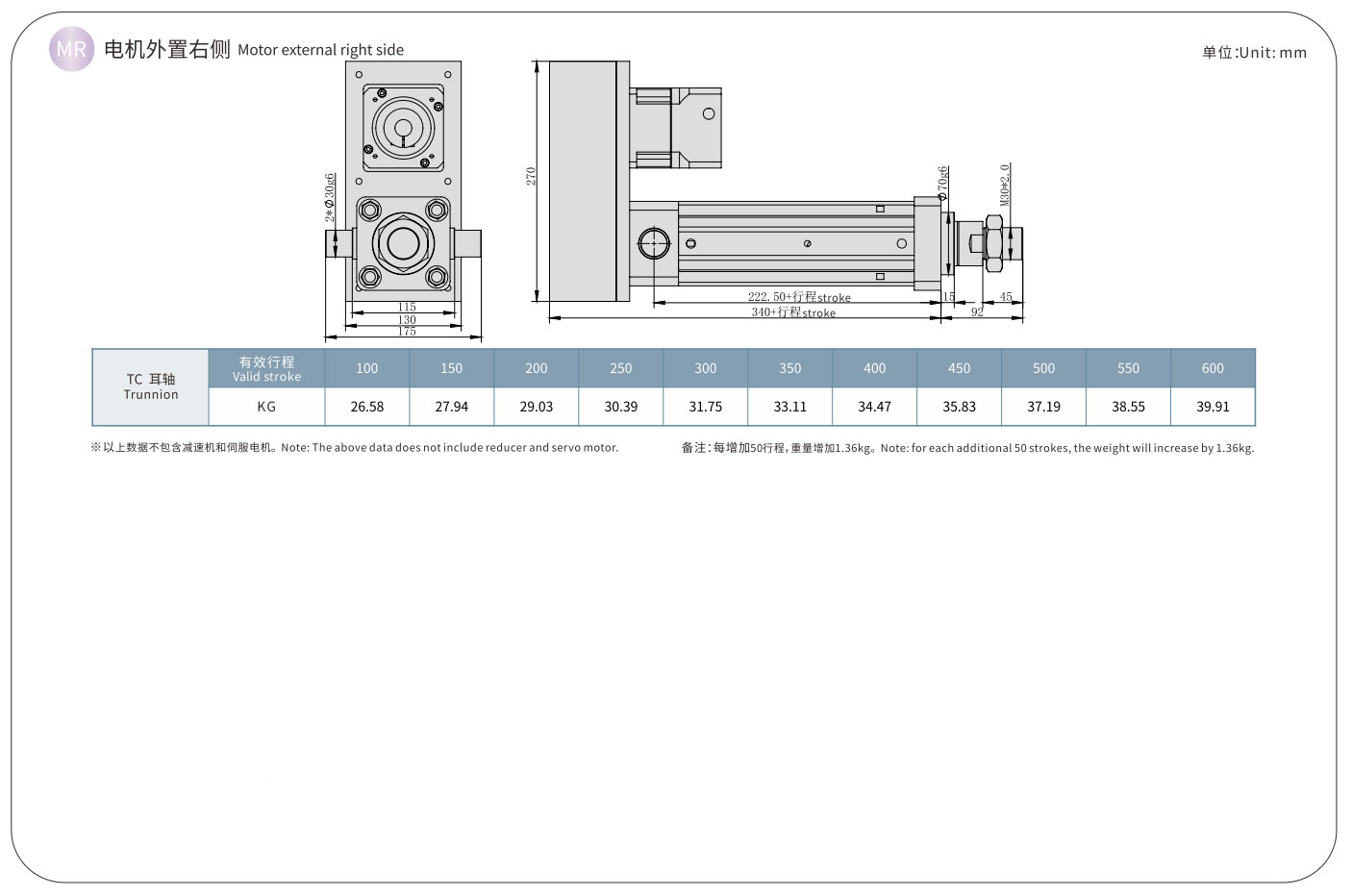

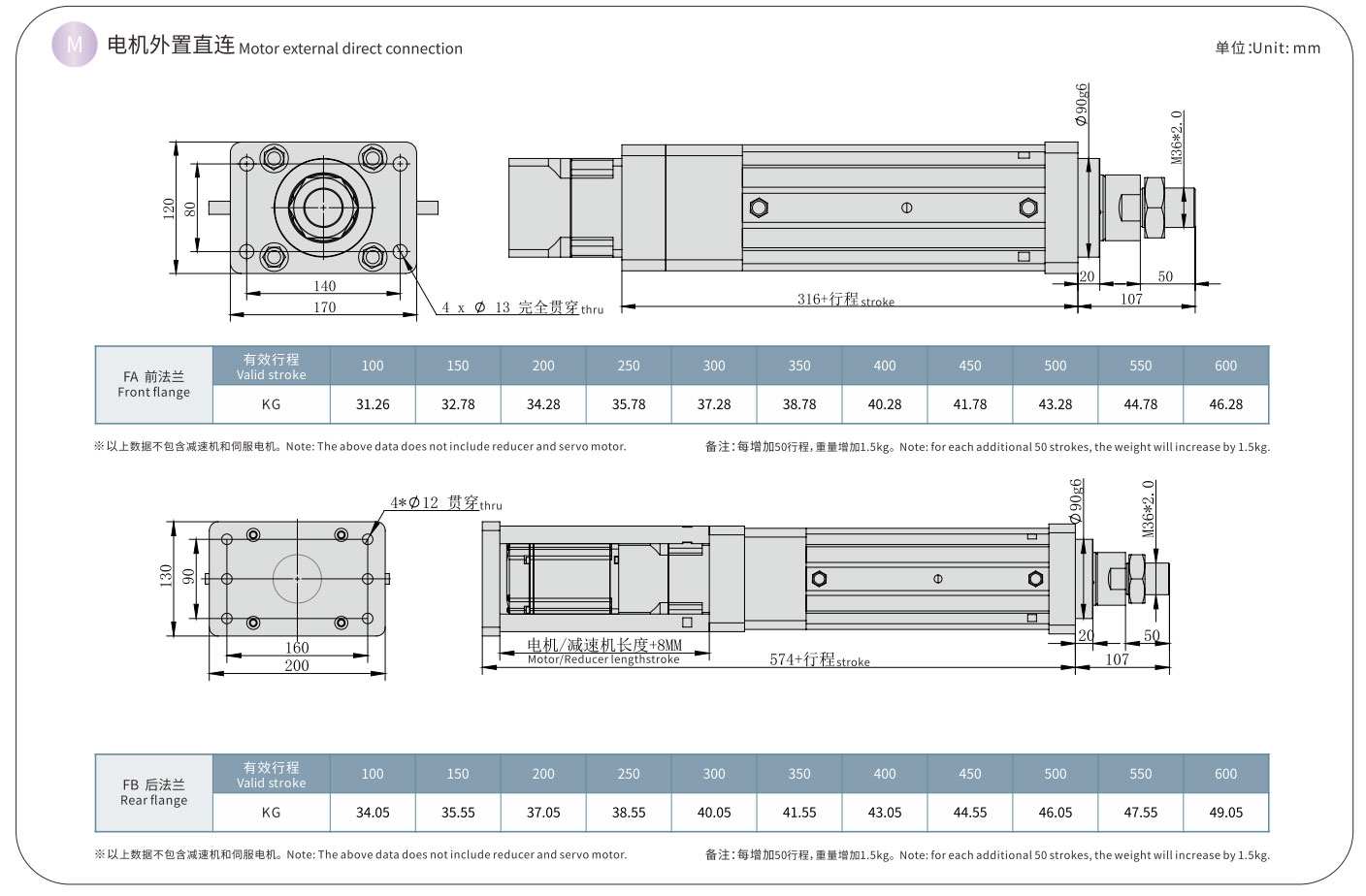

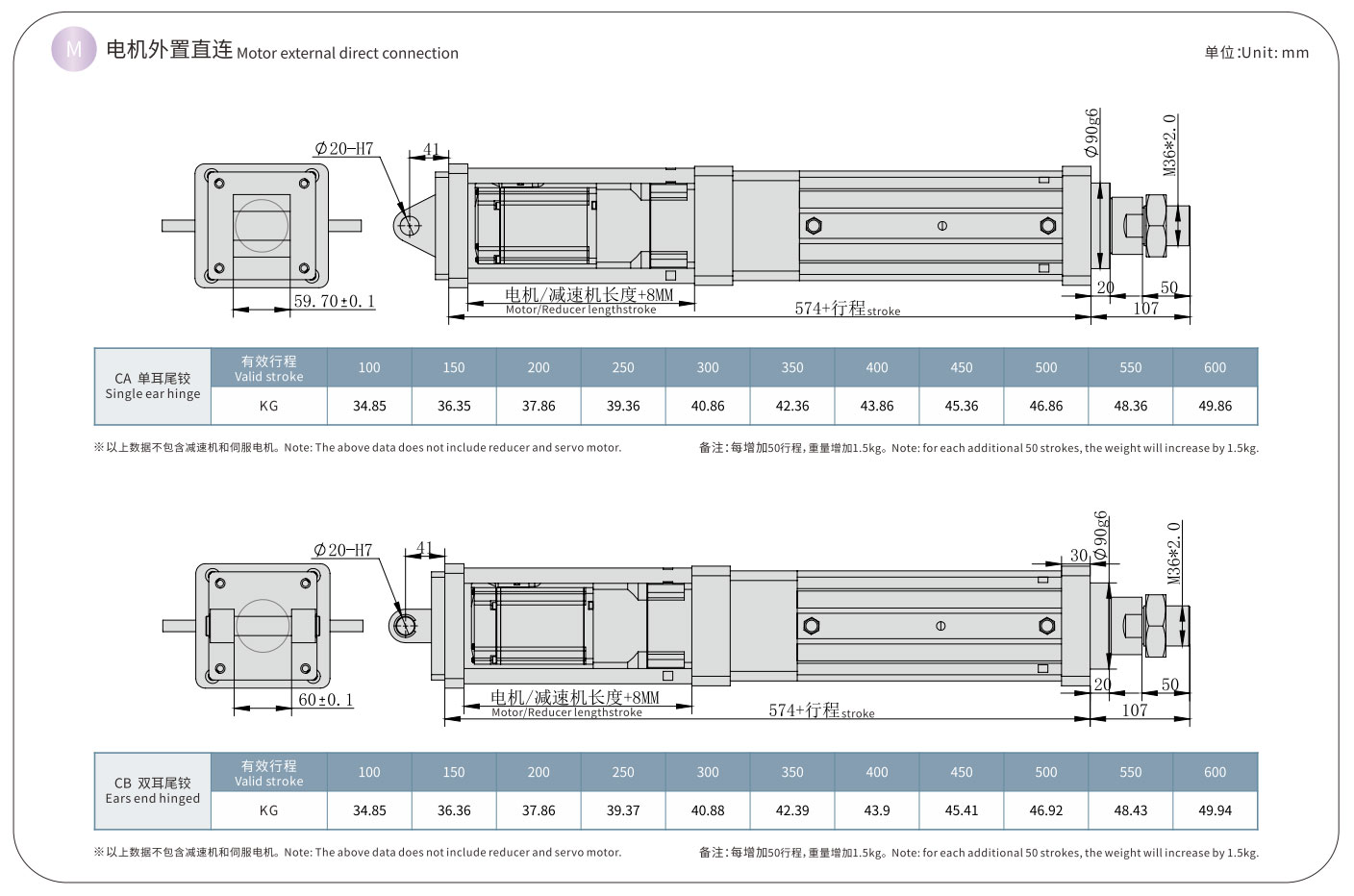

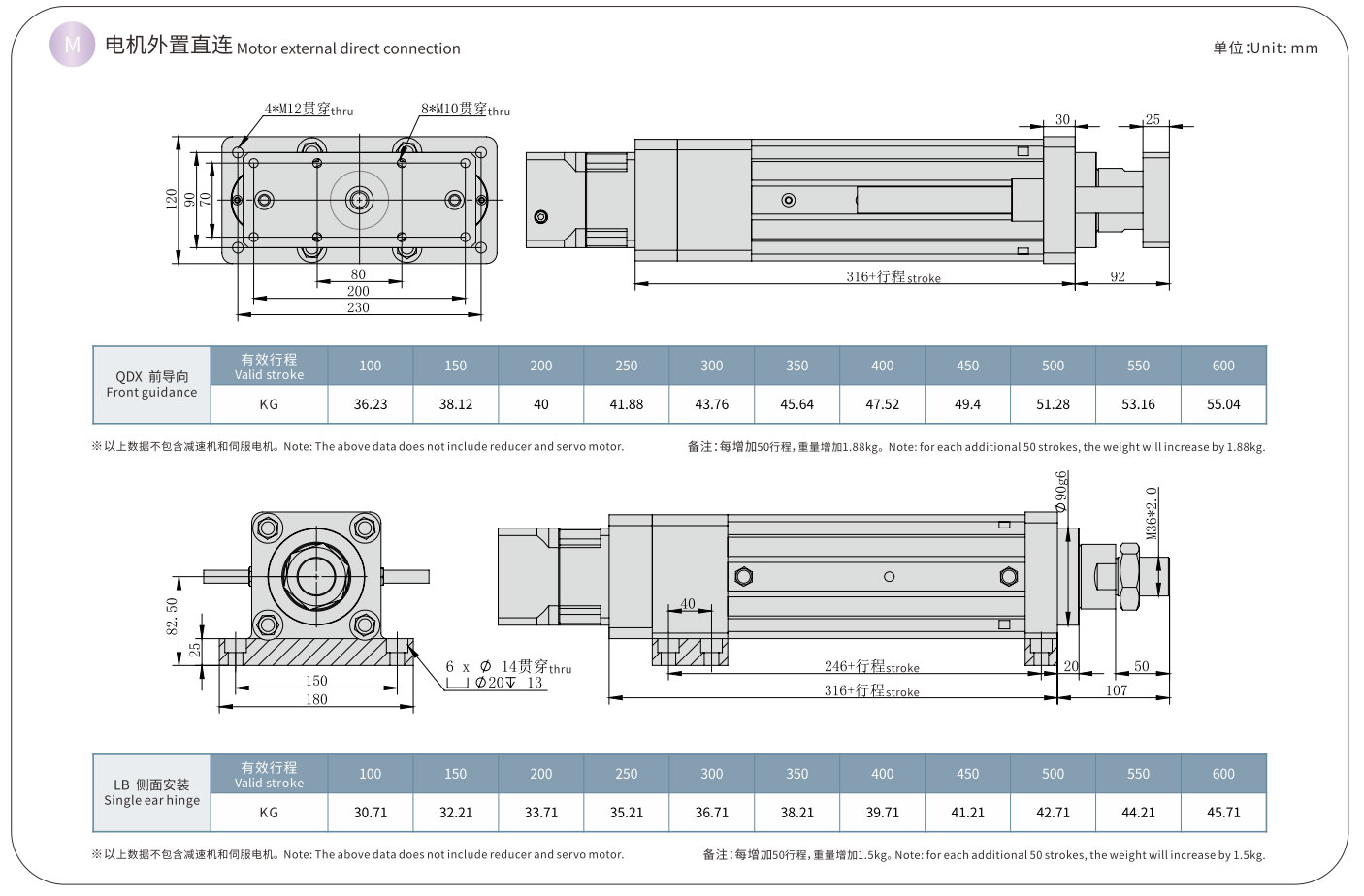

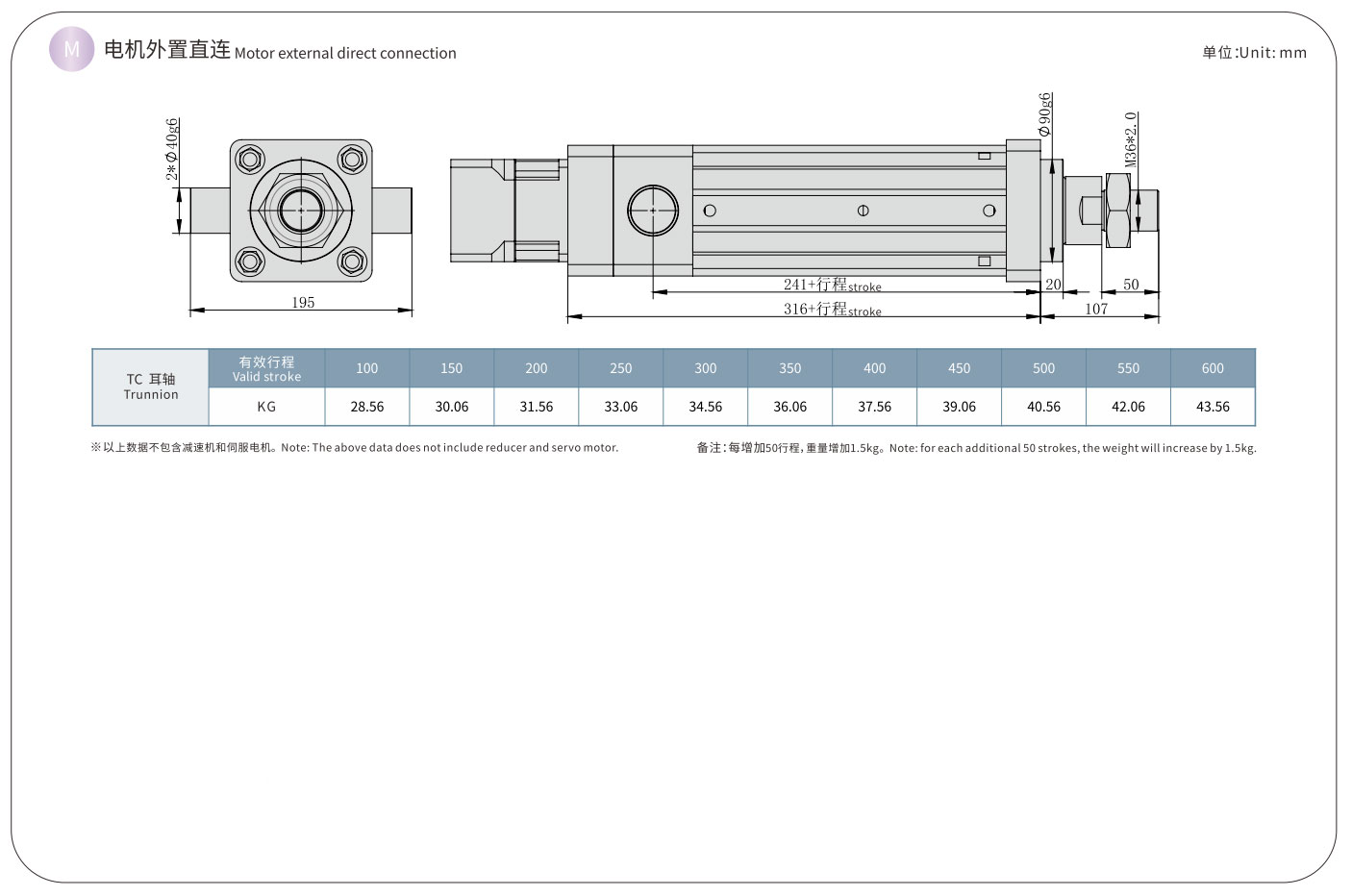

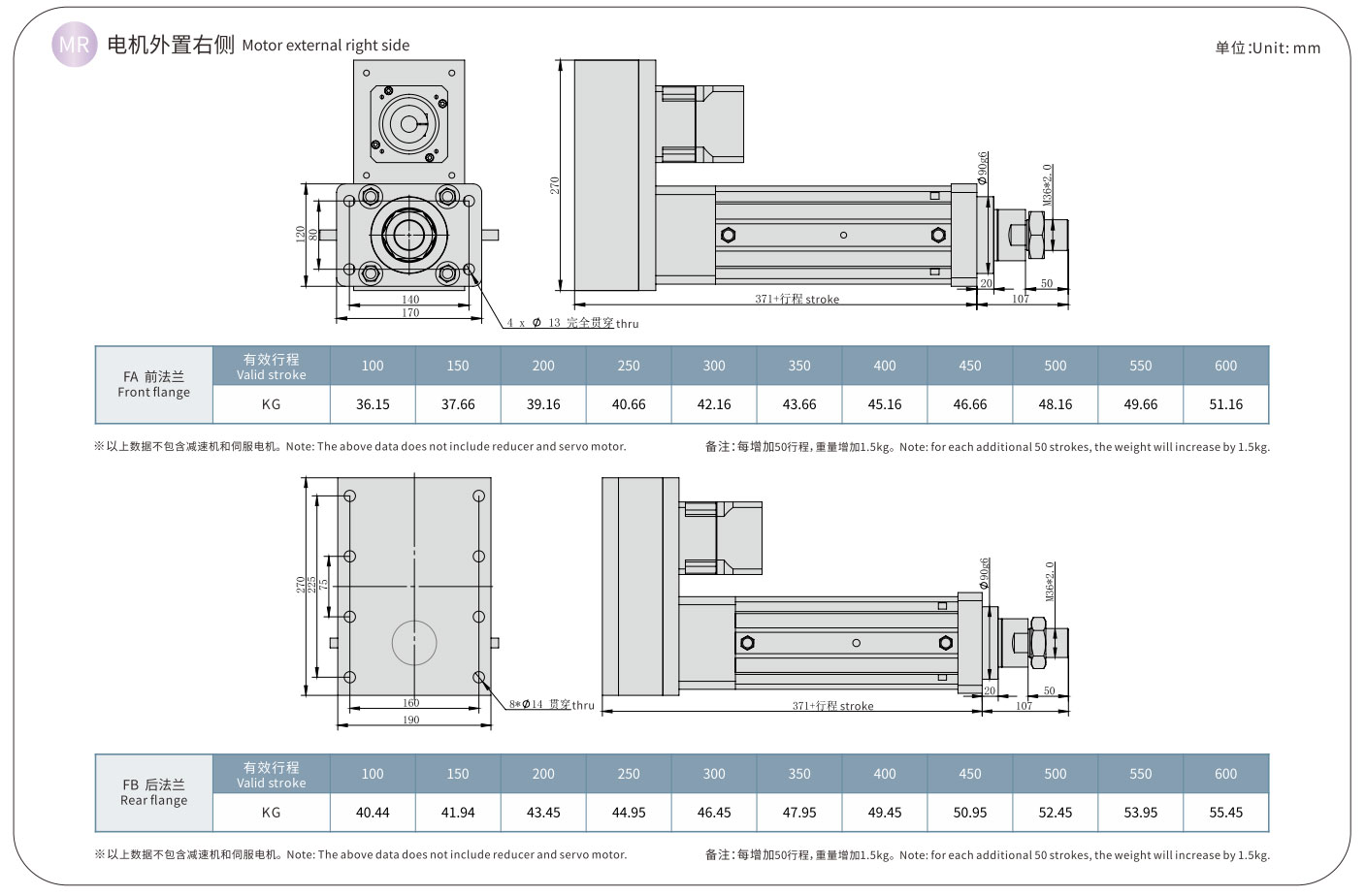

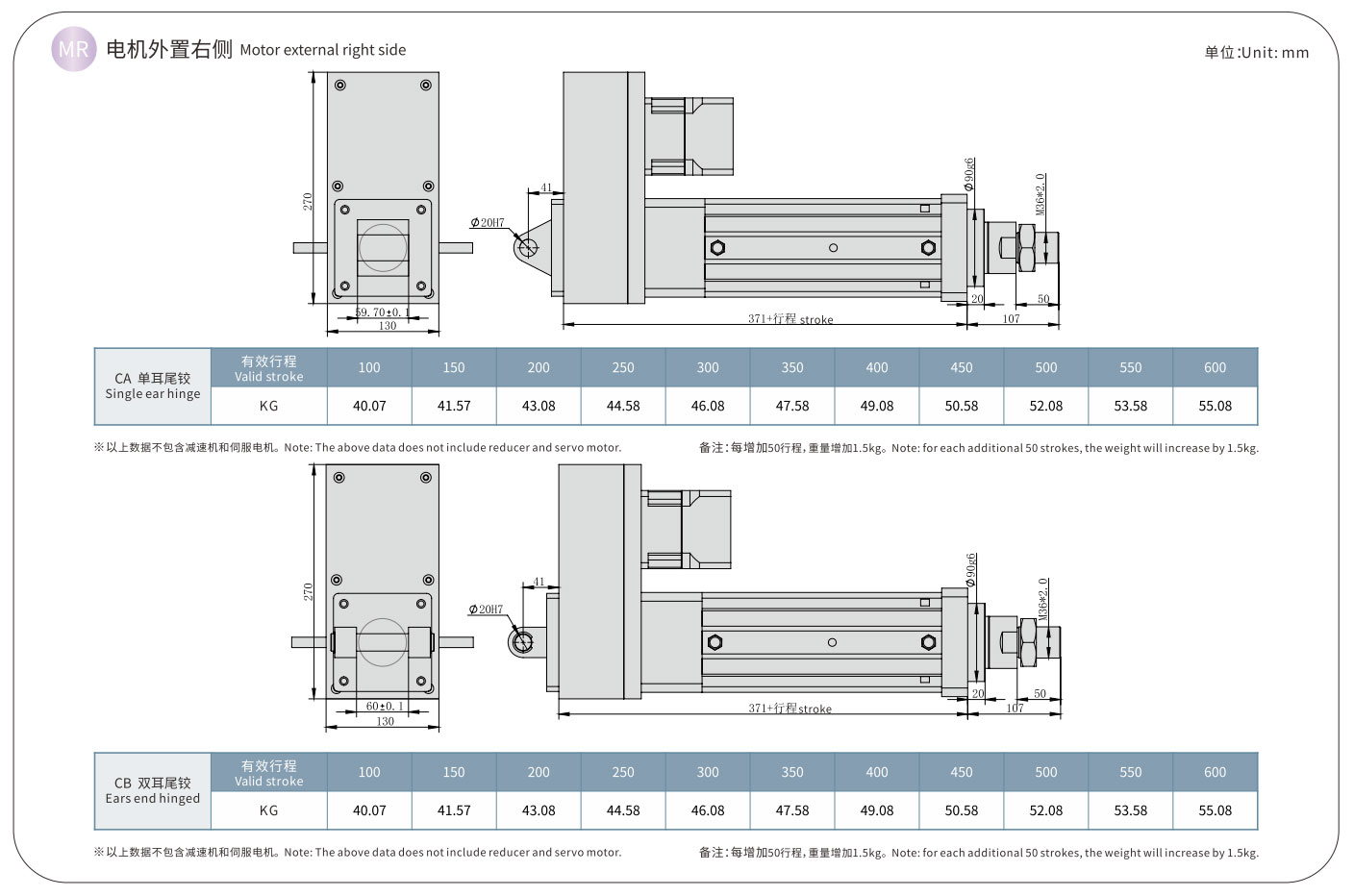

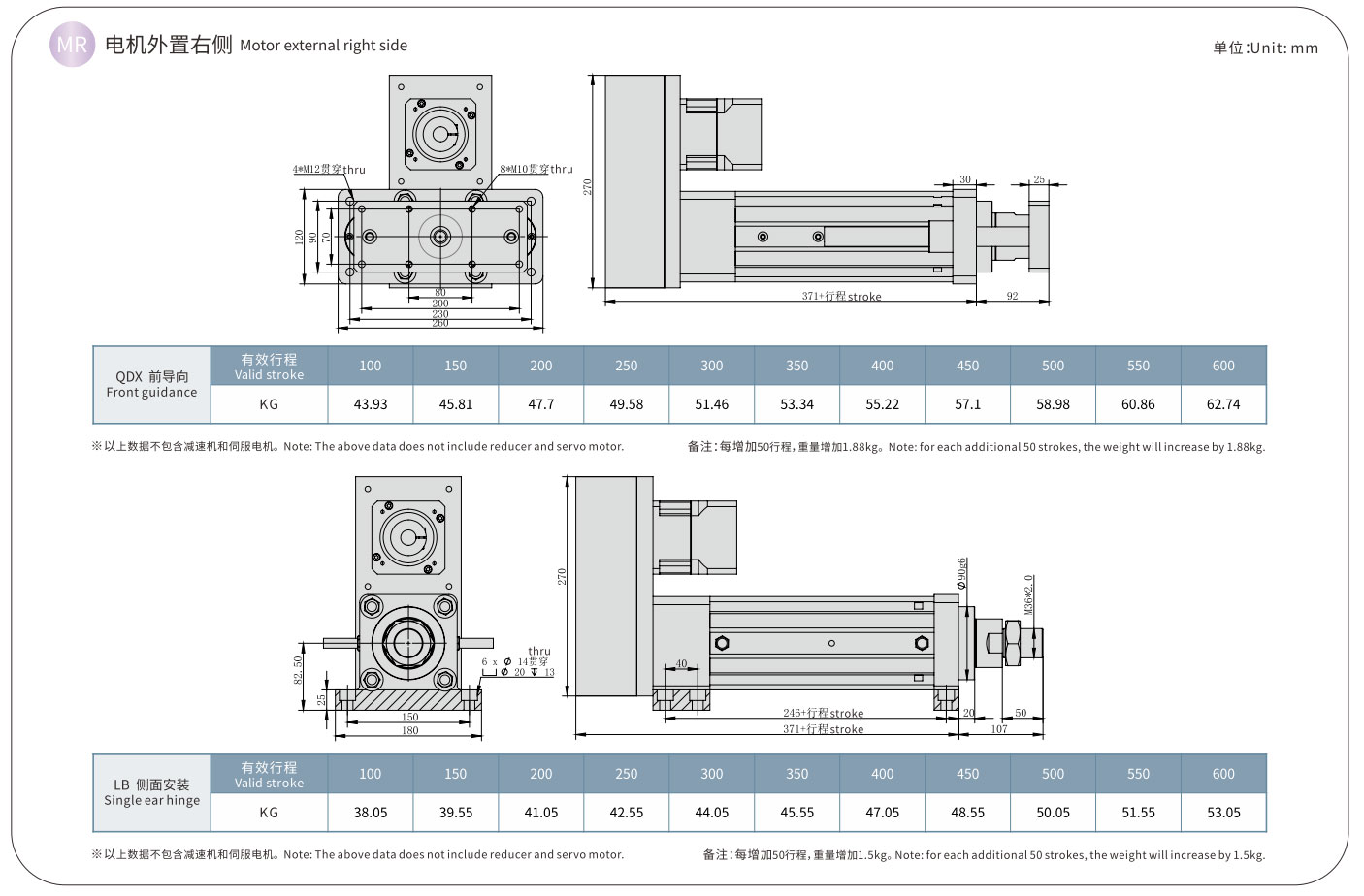

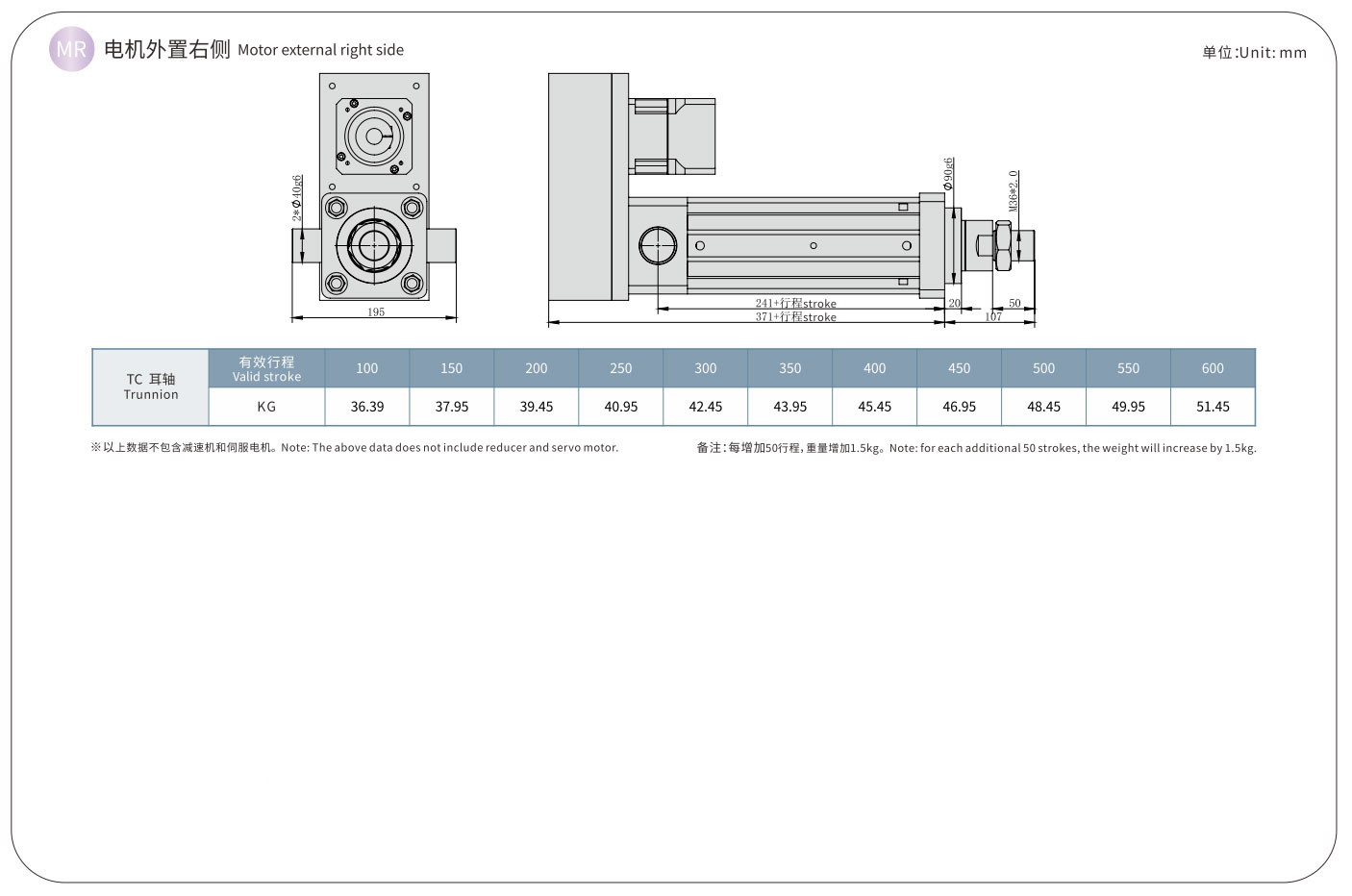

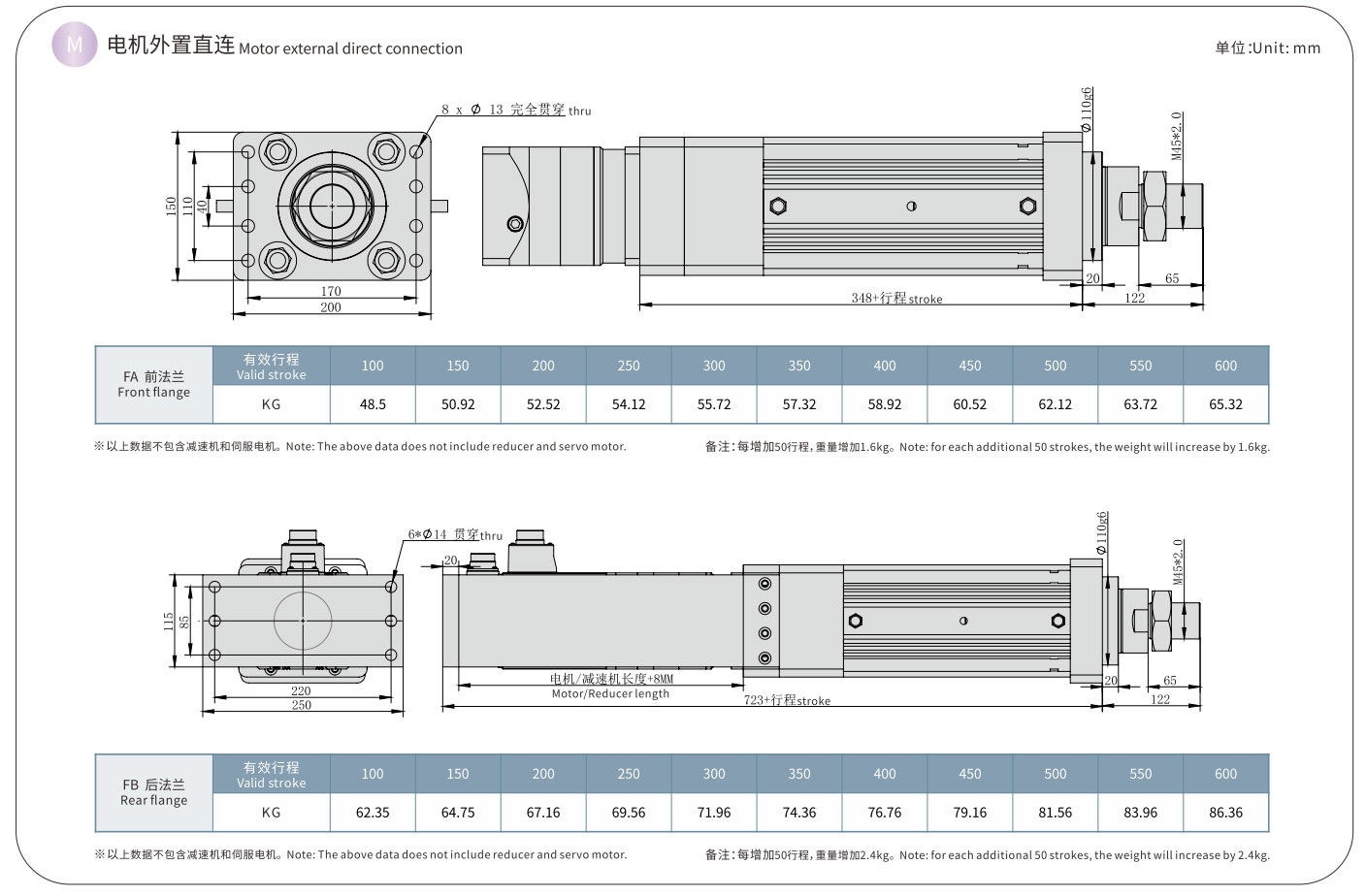

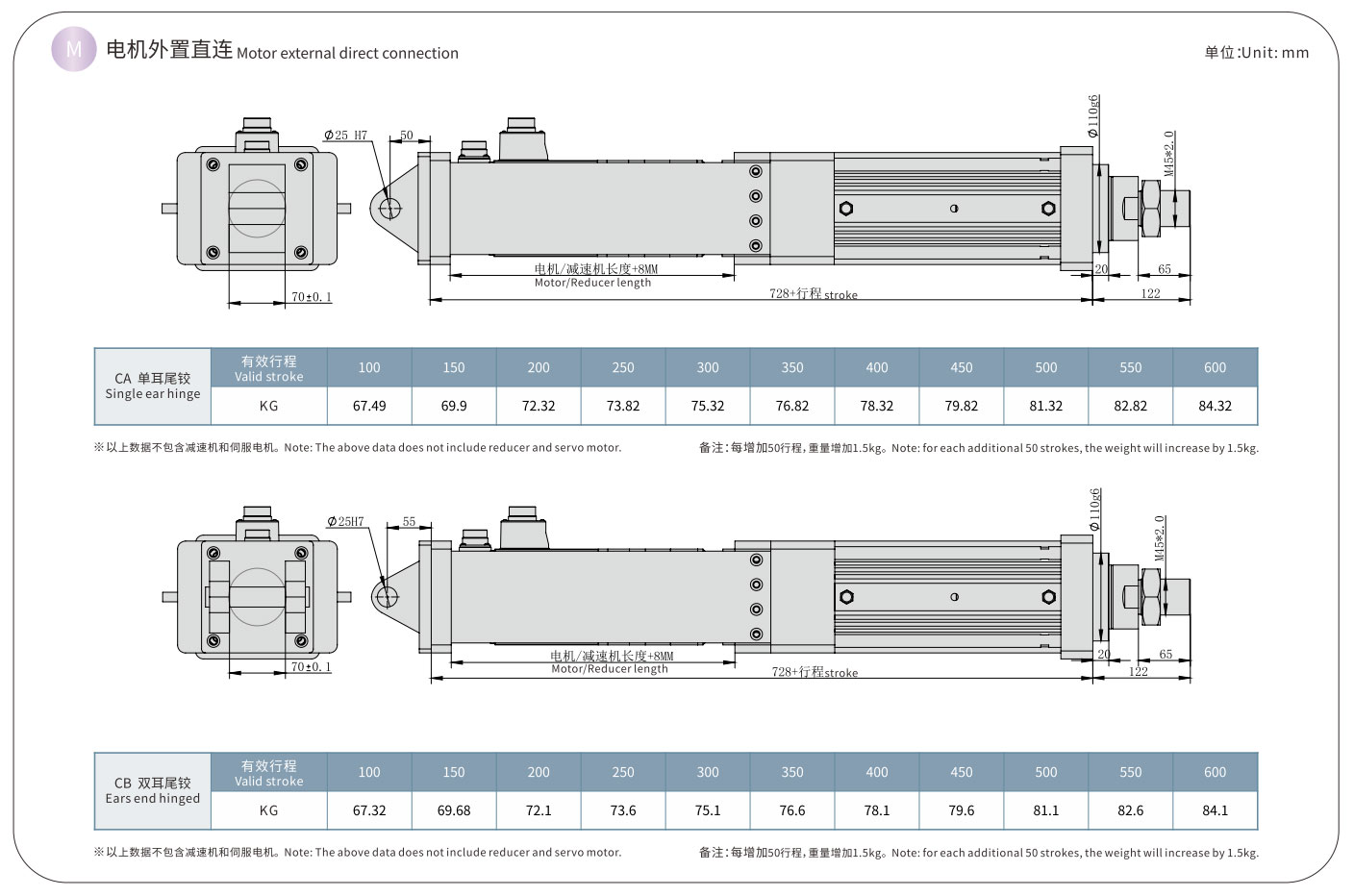

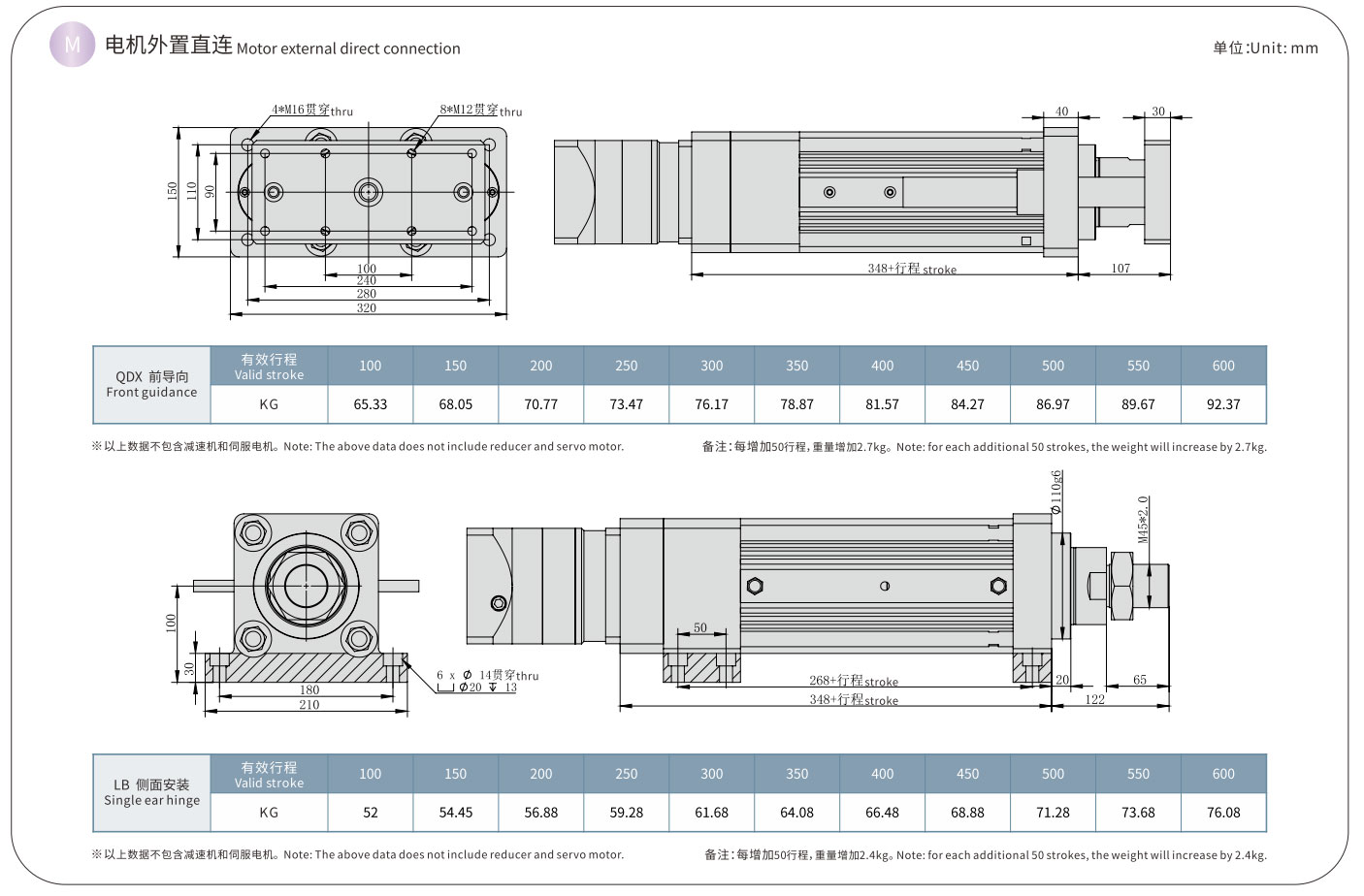

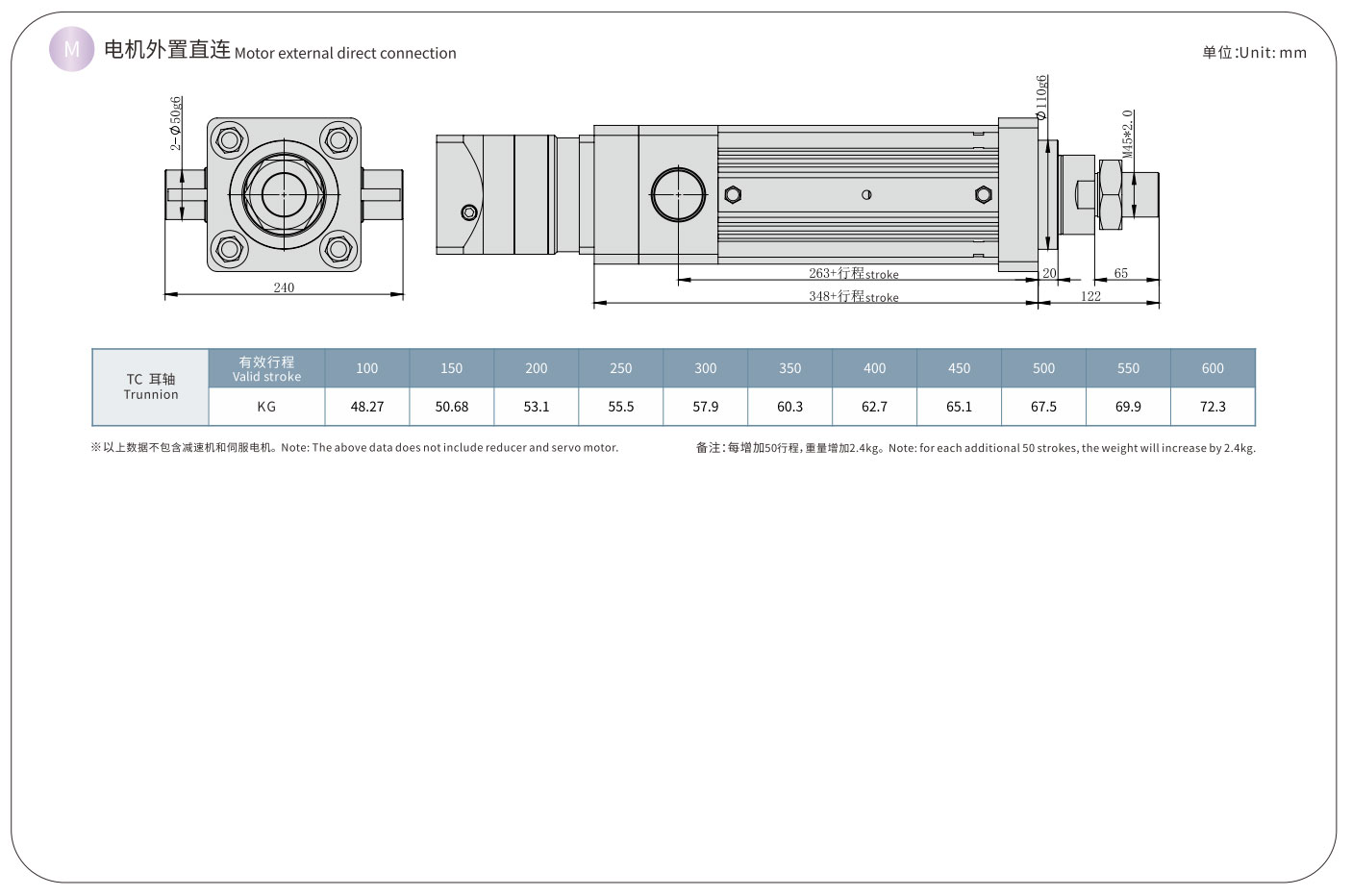

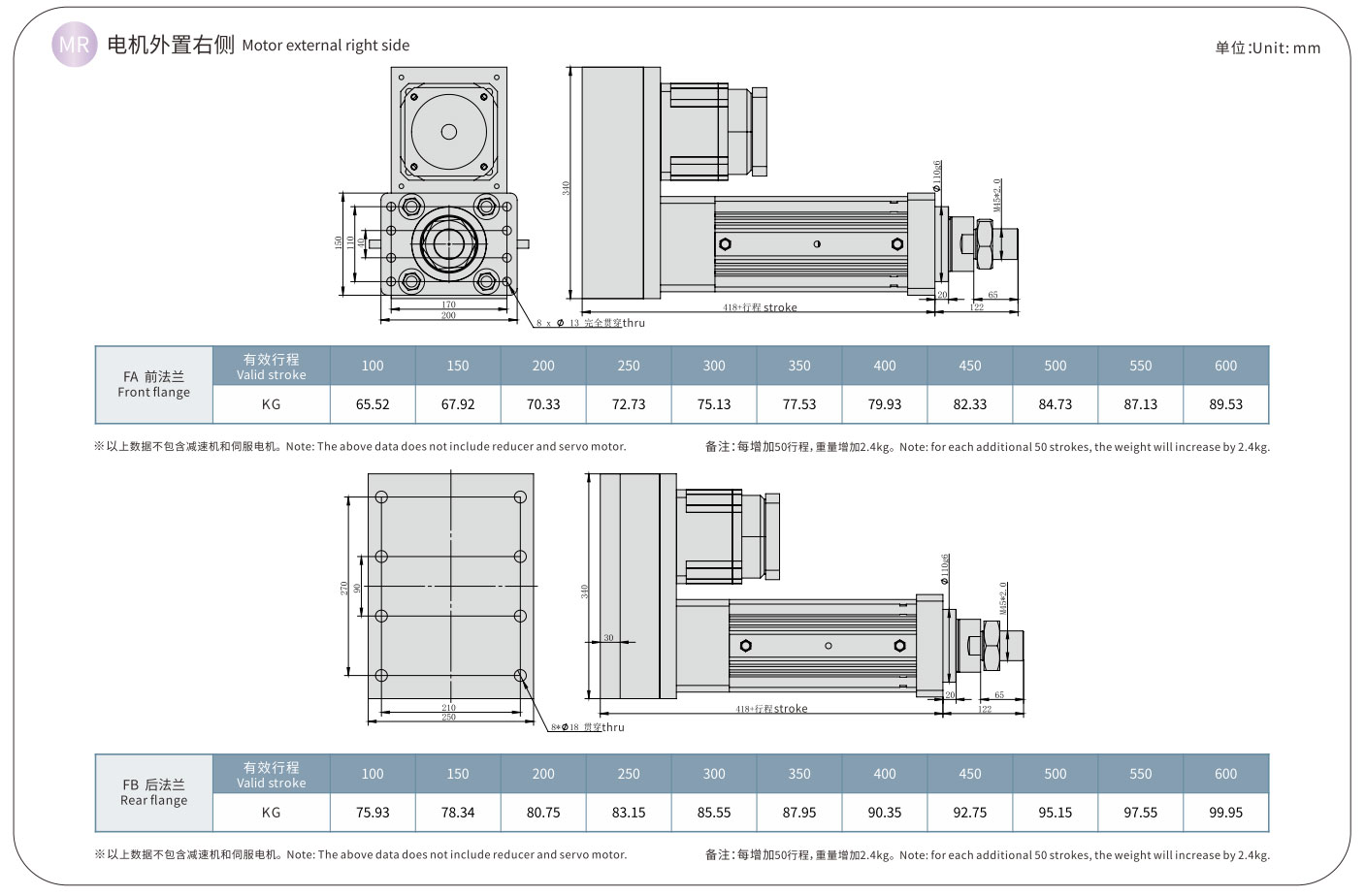

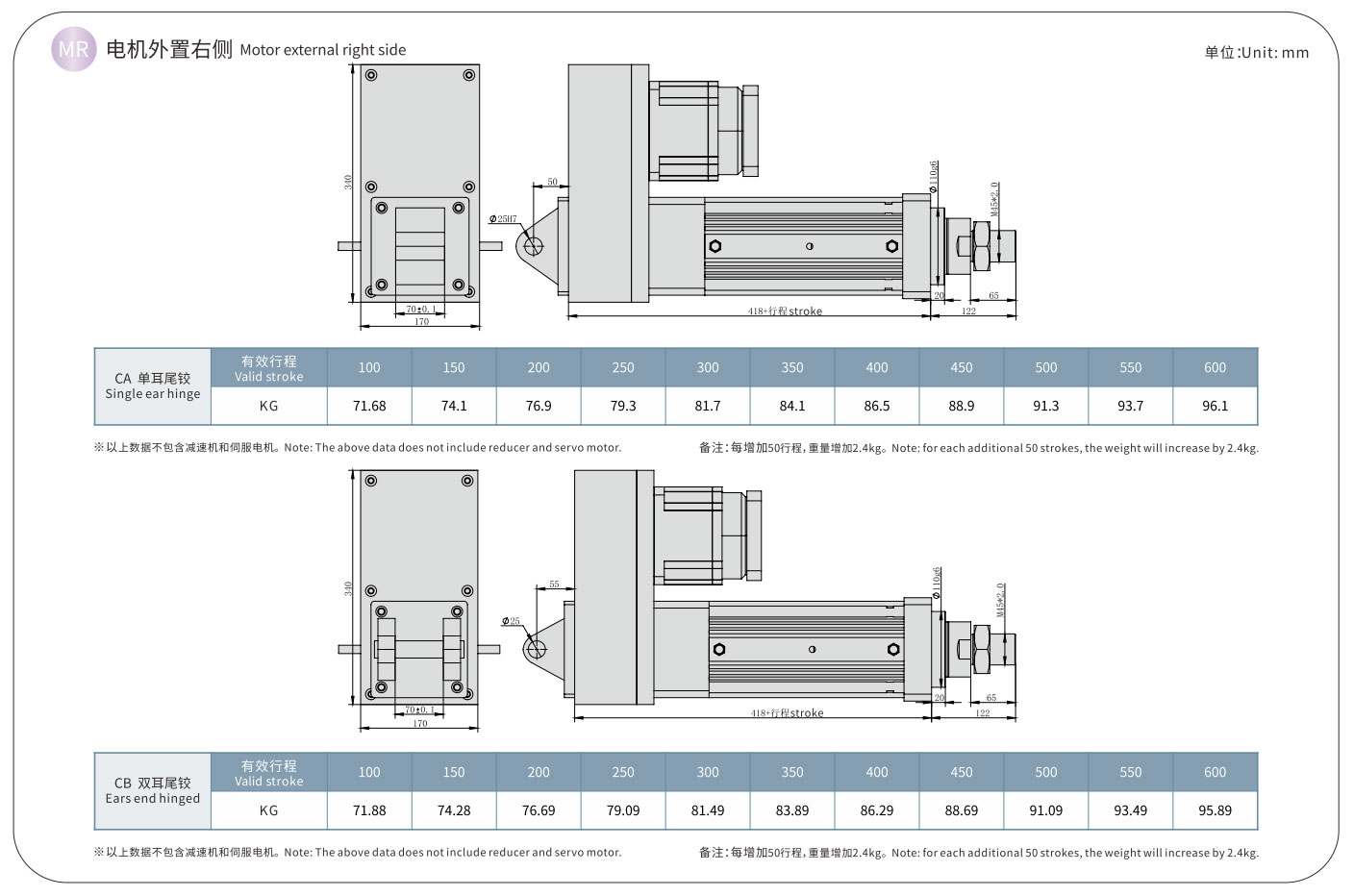

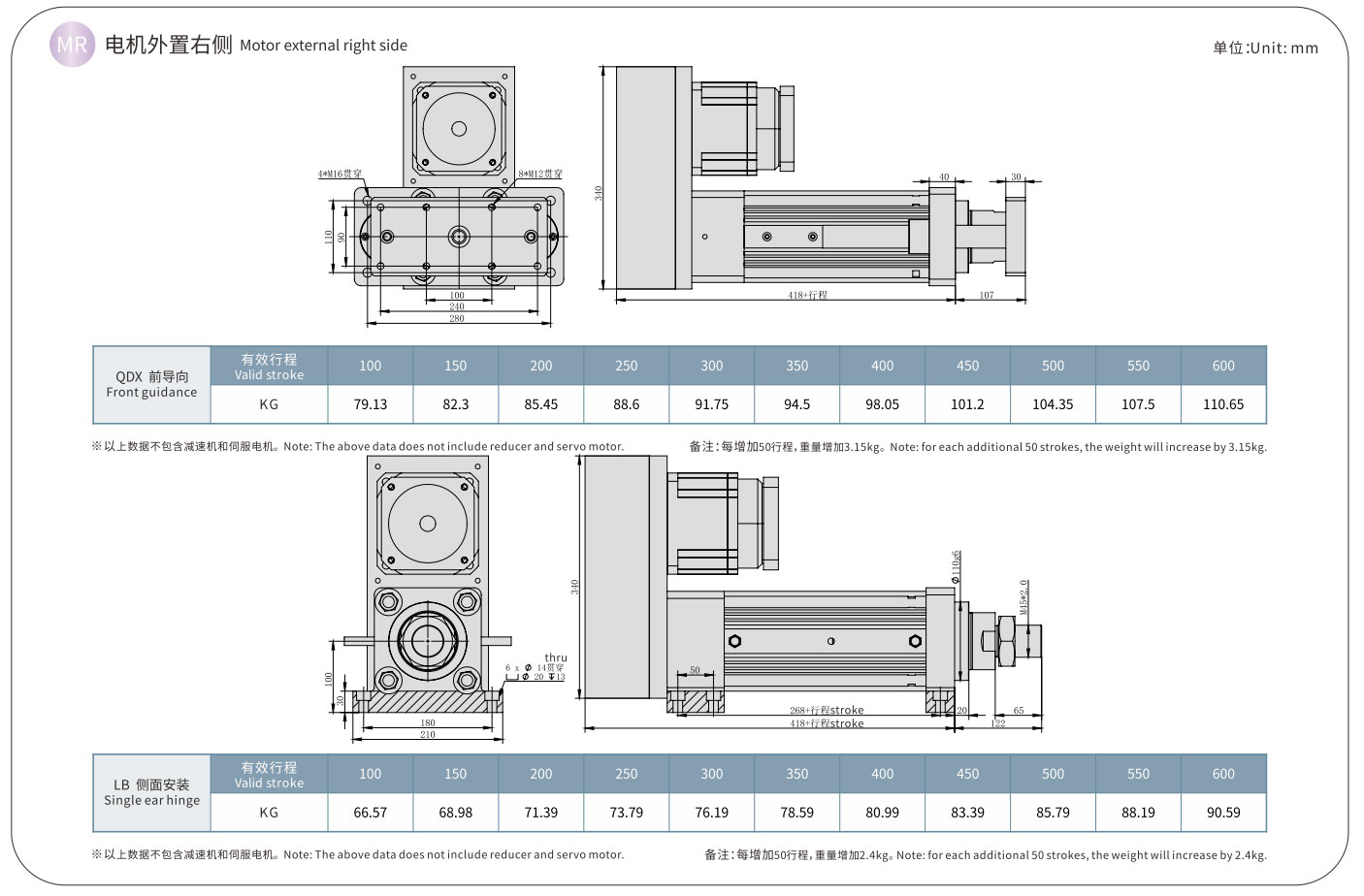

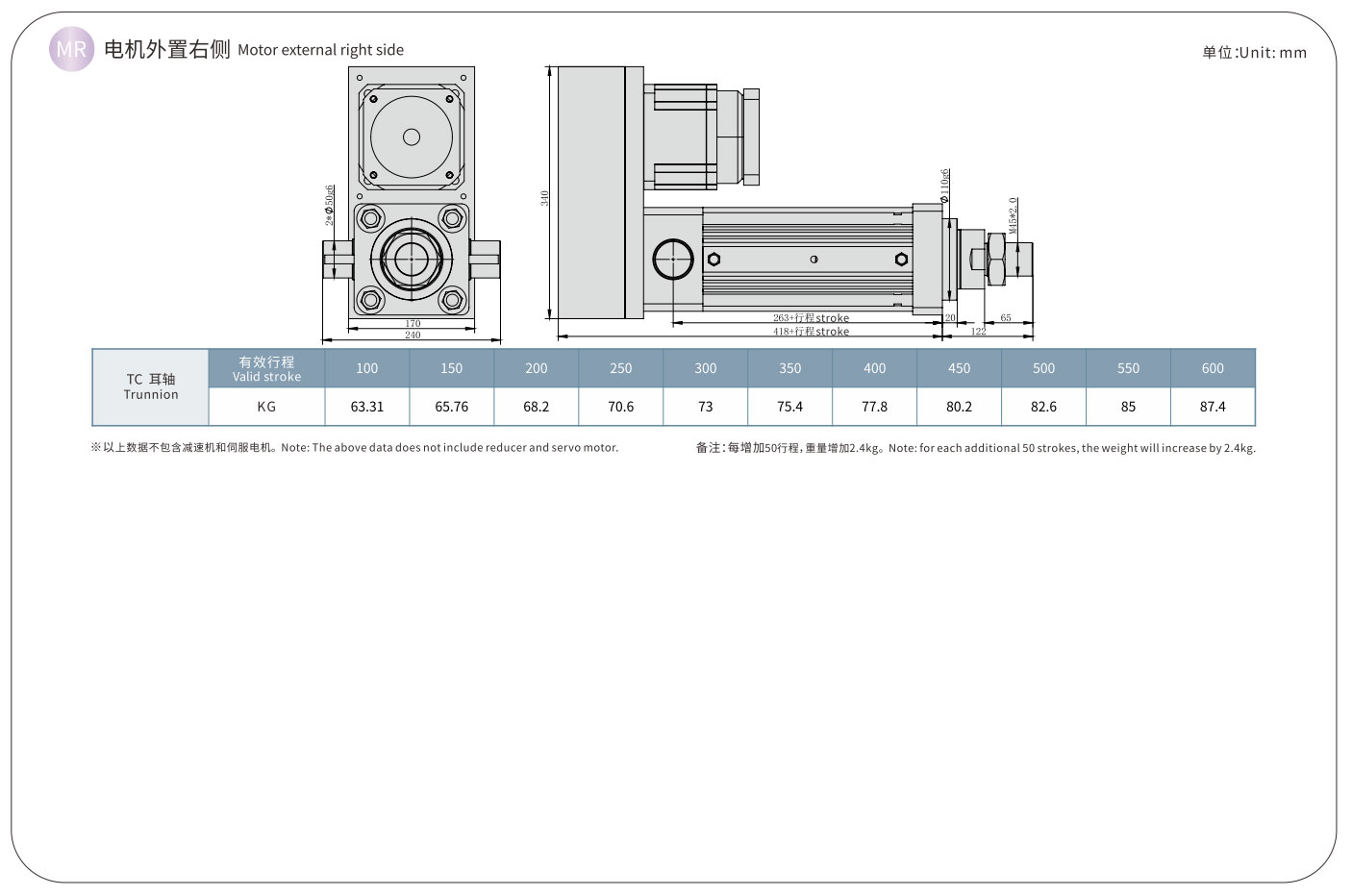

EMR series electric actuator cylinders can be flexibly matched with various installation configurations and connectors, and provide a variety of motor installation directions, which can be used for robotic arms, multi-axis motion platforms and various automation applications.

Features

Repeated Positioning Accurac y: ±0.02mm

Max Payload: 5000kg

Stroke: 100 – 1600mm

Max Speed: 500mm/s

EMR series electric cylinder adopts roller screw drive inside, the structure of the planetary roller screw is similar to that of the ball screw, the difference is that the load transmission element of the planetary ball screw is a threaded ball instead of a ball, so there are many threads to support the load, thereby greatly improving the load capacity.

Since the lead is a function of the pitch of the planetary ball screw, the lead can be designed as a decimal or an integer. The lead of the ball screw is limited by the diameter of the ball, so the lead is standard.

Planetary roller screw transmission speed can reach up to 5000r/min, the highest linear speed can reach 2000mm/s, and the load movement can reach more than 10 million times. Compared with the modern international advanced ball screw, its axial bearing capacity is more than 5 times higher , The service life is more than 10 times higher.

More products